Catalog excerpts

Acoustic Soil & Waste Plumbing & Drainage Solutions

Open the catalog to page 1

Acoustic Soil & Waste The Marley dBlue acoustic soil & waste system is designed for use where improved levels of soundproofing are required. Used in conjunction with the acoustic pipe clips, the dBlue system is designed to reduce noise and acoustic vibrations to a level of applications as well as hospitals and hotels and other commercial applications, where reduced noise levels are preferred. P.4 Research into the system Material formulation P.5 Triple-layer pipe structure P.6 Noise reduction in soil and waste systems P.7 Reduction of noise inside the pipeline and its transmission P.8...

Open the catalog to page 2

Acoustic Soil & Waste dBlue The system Triple-layer pipe structure Material formulation Aliaxis – Research & Development Institute Research into the system One of the first soundproof soil and waste systems, developed and designed as a European project at the Aliaxis Research & Development Institute. The main objective of this project was to develop a new generation soundproof soil & waste system that could be used not only in buildings with a high specification but also in multi-occupancy apartment buildings, hospitals, hotels and other commercial applications. At the same time, it also...

Open the catalog to page 3

Acoustic Soil & Waste dBlue Noise reduction in soil and waste systems Every object in motion makes noise transmitting its vibrations – in the form of pressure or negative pressure waves – to the surrounding air. There are two types of noise in soil and waste systems: Air borne noise – coming from pipelines, generated by waste water flowing inside. In this case, a soundproof soil and waste system should limit the propagation of air borne noise and keep it inside the pipes. This is achieved by using a special material formula (using minerals), a three-layer pipe structure, the quality of...

Open the catalog to page 4

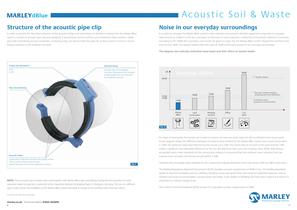

Acoustic Soil & Waste dBlue Structure of the acoustic pipe clip Noise in our everyday surroundings In order to provide the described reduction of the acoustic bridge and transmission of vibrations coming from the Marley dBlue system, a system of acoustic pipe clips was designed. A special body section and the use of elastomer inlays provide a stable grip while maintaining acoustic properties. Cushioning inlays are placed inside the pipe clip at three points to ensure a secure fixing is achieved to the building’s structure. It is useful to compare the Marley dBlue system’s noise reduction...

Open the catalog to page 5

Acoustic safety of rooms Acceptable noise levels The acceptable noise level that a human being can be exposed to while performing everyday activities and relaxing is described as "the threshold noise level value". According to the valid regulations, there are two categories of noise tests: Category I: Noise measured outdoors, i.e. in the neighbouring area, surroundings and open space. According to European Directive No.2002/49/EC, generally speaking, the noise acceptable in a built-up area at daytime is 60dB Category II: Noise measured indoors. "Building acoustics. Protection of rooms...

Open the catalog to page 6

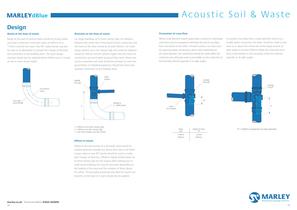

Acoustic Soil & Waste dBlue Design 3. Suspended pipe work 1. arrier passage and pipe clip location B The location of pipe clips is an important factor that has to be taken into consideration while designing and installing the system. Additionally, detail “A” presents the recommended method of passing a soundproof duct through a construction barrier. Each passage should be secured with a sleeve made of material that prevents moisture and ensures acoustic insulation (preventing acoustic bridges with the building’s construction elements – ceilings, walls). Fig. 17 The arrangements of brackets...

Open the catalog to page 7

Acoustic Soil & Waste dBlue Design Bends at the base of stacks Branches at the base of stacks Prevention of cross-flow Bends at the base of vertical stacks should be of long radius and have a minimum centre line radius of 200mm on a 110mm nominal size stack. Two 45° radius bends may also be used as an alternative to provide the change of direction and connection to the building drain. The same design principle should also be adopted where offsets occur in stacks of one or more storey height. For single dwellings up to three storeys high, the distance between the centre line of the lowest...

Open the catalog to page 8

7. Full dimensional standardisation With a view to facilitating installation works and connecting the Marley dBlue system to other soil and waste systems as well as connecting those systems to the Marley dBlue soil and waste system, full dimensional standardisation of the system was maintained, according to EN 1451. This means that connections of all diameters can be made without any need to use adapting connectors for non-standard diameters. Basic examples of connections are presented opposite. CAST IRON Transitional coupling marley.co.uk Technical hotline: 01622 852695 Acoustic Soil &...

Open the catalog to page 9

Acoustic Soil & Waste dBlue Installation Cutting pipes and jointing Prior to cutting the pipe and jointing it to another pipe or fitting, measure the necessary pipe section allowing for the pipe socket depth. Photo. 1 Photo. 2 Cut the pipe using a pipe cutter (Photo 1) or a fine-toothed saw (Photo 2), with particular attention to keeping the angle 90°C. Photo. 3 Photo. 4 Another important factor prior to making the connections is to bevel the pipe end properly, using a chamfering tool or coarse file to provide a 15° bevel on the end of the pipe. Photo. 5 Photo. 6 When connecting the pipe...

Open the catalog to page 10

Acoustic Soil & Waste dBlue Installation Photo. 9 Photo. 10 Using a level (Photo 9), determine the length of the Marley dBlue soil stack. On the run line, measure the points (Photo 10) where the pipe clips will be fixed and horizontal connections to the sanitary fittings made. Photo. 11 Photo. 12 Photo. 13 Photo. 14 In the final stage, put the pipe or fitting inside the pipe clamp under socket (Photo 14) and connect the two parts of the open pipe clip with a drill-driver (Photo 15). Photo. 15 Photo. 16 Next, drill holes applicable for the diameter of fixing (Photo 11) on the pipe line. Fix...

Open the catalog to page 11All Marley Plumbing & Drainage catalogs and technical brochures

-

New Product Guide MARCH 2021

3 Pages

-

Roofing Accessoiries

33 Pages

-

Multikwik®

50 Pages

-

Underground

27 Pages

-

PRODUCT PORTFOLIO

11 Pages

-

Rainwater

23 Pages

-

ABOVE AND BELOW GROUND

41 Pages

-

soil waste

27 Pages

-

ABOVE GROUND

35 Pages

-

Anti-flood valve datasheet

2 Pages

-

HPDE Drainage

27 Pages

-

Sanitary Systems technical guide

17 Pages

-

Sanitary Systems Brochure

13 Pages

-

Marley Range

11 Pages

Archived catalogs

-

underground drainage system

23 Pages

-

PRODUCT PORTFOLIO_2017

11 Pages

-

RAINWATER_2017

19 Pages

-

Marley Sanitary

13 Pages

-

Marley Rainwater

28 Pages