Catalog excerpts

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS RGK REGLAIR PRECISION CONTROL DAMPERS PRODUCT DESIGNATION RGK-10…, RGK-15…, RGK-17…, RGK-30…, RGK-50…, RGK-51… TECHNICAL SPECIFICATIONS Max. size WxH: 7900 mm x 7900 mm (subject to shipping) Max. slat length: 100 mm slat max. 2000 mm, 150 mm slat max. 2500 mm Max. air velocity: 20 metres per second Closing torque: M (Nm) = (0.23 x Q) + (B(m) x Q) Closing torque with MS: M (Nm) = (0.46 x Q) +( B(m) x Q) M = closing torque in Nm, B = damper width, Q = number of slats Closing direction: clockwise as standard Air flow direction: freely selectable Free cross section: > 60 % (more precise figures after calculation by manufacturer) ATEX RGK dampers are only approved in specific designs and with appropriate identification for Zones 1, 21 21 and 22 according 2, or 2, 22 according to ATEX Directive 2014/34/EU. to ATEX Directive 94/9/EC. If the fitter or operator changes the dampers in any way, the ATEX approval becomes null and void. It is important to ensure that the damper and additional equipment are installed in compliance with zoning requirements. In principle, avoid all damage caused by external influences. Never lift dampers by the slats or the outer linkages. Dampers with a maximum weight of 50 kg can be lifted by the C-profile frame. With heavier dampers, use at least four points at the corner angles as suspension points. Do not use individual slats under any circumstances as footholds during installation. Report any damage, e.g. deformation of slats, dents, impacts or warping of the C-profile frame etc. immediately to the supplier or manufacturer. This may impair the proper functioning of the damper and at best cause dangerous circumstances to occur. Mount the dampers warp-free, tension-free, on a flat surface and without any angular errors in the damper frame. When mounting, use the 4 corner holes provided as standard. With larger dampers, fit additional flange couplings at spacings of 200 - 500 mm. This is the responsibility of the planning engineer or fitter. When installation is complete, check the angle of the damper frame. It must be exactly 90°. Correct any deviations immediately. In addition check the free movement of the slats, linkage and gear wheels. Avoid as far as possible any reduction in freedom of movement on customer premises when installing insulation materials, installation ducts, auxiliary structures etc. If this is not observed, it can lead to considerable disruptions in operation, e.g. slats rub against the damper frame, increased damper torque, damper fails to open or close, reduced leak tightness, fatigue fractures on the axles etc. Only dampers which are equipped with collar bushings can be fitted with vertical slats (also called standing slats). In addition, make sure with this damper application that additional bolts or reinforcements are affixed with dampers larger than 1000 x 1000 mm. The lower frame profile on which the entire slat weight rests must also be supported by the customer. Sagging can lead to damper damage and plant outages. ATEX: Under no circumstances may ATEX dampers be fitted after a fall or impact with visible or concealed damage. On models with side seals (Di, DIN, CEN, S etc.) protect the units from impurities of all kinds during the installation phase. Drilling swarf and concrete chips can damage the side seals. Before starting up the dampers, wipe the side seals thoroughly until they are dry.

Open the catalog to page 1

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS ATEX: All relevant national and international standards and regulations for Ex zones must be observed. On dampers with ATEX functionality in particular, the damper housing must be earthed using the earthing braids attached by the manufacturer. No mechanical changes may be made to the product. In addition do not attach any components (motors, limit switches, etc.) to the damper if they have not been analyzed for ignition risk by the appropriate manufacturers or approved for ATEX zones. It is prohibited to drill holes or fit bolts or screws...

Open the catalog to page 2

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS RGK REGLAIR PRECISION CONTROL DAMPERS Depending on the degree of soiling of the medium, carry out a dry clean from time to time. In addition operate the dampers at least four times a year according to the plant-specific conditions. This prevents the slat seals from sticking in closed state. The slide bearings can be blown off using compressed air as required, although they are basically maintenance-free (lubrication). Otherwise the RGK models operate maintenance-free. Only LUCOMA genuine spare parts may be used for all repair and...

Open the catalog to page 3All Lucoma catalogs and technical brochures

-

Non-return damper

1 Pages

-

inspection Doors

2 Pages

-

WSG-H3

1 Pages

-

Anleitung-Grillair

2 Pages

-

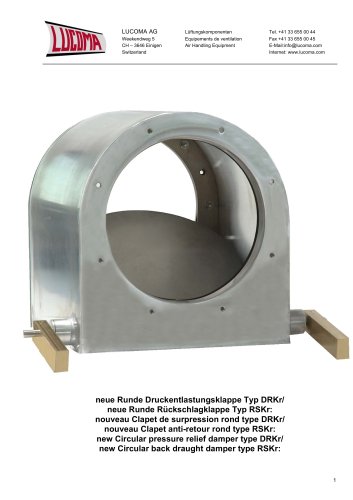

Anleitung-DRKr-RSKr

2 Pages

-

Anleitung-RSK-DRK

2 Pages

-

RSK

4 Pages

-

DRK

4 Pages

-

RGKr

1 Pages

-

wsg

8 Pages

-

control dampers

6 Pages

-

New range

4 Pages