Catalog excerpts

Thanks to its undisputed advantages, UV Bonding Technology has become even more common during the years: versatility , as it allows to bond different materials as well as complex shapes, and its short execution times with the relative cutback of production costs. its The information here contained are the result of our technical and practical experience that we gained over the years working in the field of industrial and artistic glass. Nevertheless, each application is to be carefully evaluated in all its details and never underestimated. We therefor invite you to contact our technical...

Open the catalog to page 2

INTRODUCTION TO BONDING A bonding is the operation of a permanent adherence between two surfaces of the same or different materials through adhesives. By definition is an adhesive a: “Non-metallic substance capable of joining materials by surface fixing (adhesion), in order that the achieved bond has an adequate inner strength (cohesion)”. The cohesion is the inherent strength of a material. The adhesion is the molecular bonds as a whole, which are generated between the in-contact material and adhesive with the involvement of their contact area (bonding area) as well the adhesive layer near...

Open the catalog to page 3

NECESSARY CONDITION FOR BONDING A necessary condition, yet not enough, to get a good bond is the adhesive’s capacity to wet the surface to be bonded (adhesive wettability). ASPECTS THAT AFFECT THE WETTABILITY OF THE SURFACES TO BE BONDED: • Flatness is the surface’s condition where all its points belong to the same plane. The better the flatness is the more effective the bonding will be. Smooth surfaces generally need liquid adhesives while the irregular ones require viscous adhesives, which have a higher ability to fill the interstices. • The Roughness of a surface is composed of inherent...

Open the catalog to page 4

BONDING - IMPROVING SURFACE TREATMENTS Subjecting the surface to several treatments, helps to improve the effectiveness of the bonding. There are three kinds of surface treatments to mark off: SURFACE PREPARATION FLAME TREATMENT CONTROLLED ENVIRONMENT Cleansing, Degreasing By using our FIXGLASS 1000 Acclimatization the working environment has to have a humidity of <40% and an air temperature between 12°C and 35°C REQUIRED RESISTANCE The adhesive to use has to be chosen also according to the stress the bonding components are subjected to, which could be: over-time-constant weight, for...

Open the catalog to page 5

UV ADHESIVES: BY-CHEMICAL-PROCESS-CURING ADHESIVES BY UV-RADIATION EXPOSURE The necessary condition to use UV adhesives is that at least one of the materials has to be transparent to radiation ; otherwise, the polymerization will not be possible. In order to polymerize and cure need these single-component adhesives a radiation with certain wavelength and intensity. UV-curing adhesives may contain several photoinitiators that can activate the hardening with a wavelength of 365 nm (UV-A) or 405 nm (Visible Light) . Adhesives containing 365 nm photoinitiators are considered traditional, while...

Open the catalog to page 6

2)1 Fast and controlled polymerization with consequent increase in production and decrease in costs. 3) Excellent adhesion, therefore high resistance. 5)1 Possible bonding with different materials such as metal, glass, wood, plastic, marble. 6)1 No need of glass-processing operation that weaken the glass itself. UV LAMPS Traditional lamps emit UV-A rays with a peak wavelength of 365 nm. The PVB serves as a filter to the passage of those UV-A rays, so the use of lamps with a peak wavelength of 405 nm (VISIBLE LIGHT) is required. The known-as "VISIBLE LIGHT ADHESlVES" contain photoinitiators...

Open the catalog to page 7

A SKILLFULlBONDINGlDEPENDS ON: • Materials to be bonded and their flatness • Use of a proper adhesive • Preparation of the surfaces to be bonded (cleansing, degreasing, flame treatment) • Environment where the bonding will take place • Proper realization • Use condition of the object (possible stress)

Open the catalog to page 8

CHOICE OF THE ADHESIVE The wide range of available adhesives let you make the right choice according to different criteria. The materials of the item: • float glass (FIXGLASS UV 627, 630 and 629) • laminated glass (FIXGLASS UV 635, 621 and 973); • glass-glass (FIXGLASS UV 627 and 635); • glass-metal (FIXGLASS UV 630 and 621); • UVA or VL ray-filtering materials (FIXGLASS UV 629, 630 and FIXGLASS UV GEL mixed with our activator, BICOMPONENTE). Environment where the bonding will take place: • damp environment (FIXGLASS UV 629 and 973) or not. Adhesive application method: • bonding for...

Open the catalog to page 9

PERFORMING AN UV-BONDING CONTROLLED ENVIRONMENT CONDITION 1) A bonding in an environment with a temperature between 12° C and 35° C and a humidity of less than 40% is recommended. 2) Choose the right adhesive according to the materials that have to be bonded, the stress they are subjected to and the environmental condition where the item will be located, with the support of the chart on our catalogue. 3) Check the flatness of the surfaces to bond in order to get a cheaper yet effective bonding. In order to verify the correct relative positioning of the pieces case of complex products, it is...

Open the catalog to page 10

PERFORMING AN UV-BONDING 6) Clean again the surfaces with FXTNT01 soaked in our FIXGLASS 1000 first and with a neat and dry cloth then, in order to eliminate probable residuals and dirt. USE OF THE ADHESIVE IN CASE OF LOW-VISCOSITY ADHESIVES 7A) Place firmly the pieces to be bonded with the help of supports and suction cups in order to leave the necessary space to let the adhesive to seep all across the surface by capillarity. 8A) Apply the adhesive sideways letting it seeping by capillary action. In case of adhesives with a higher viscosity, a longer seeping time is required. Be sure that...

Open the catalog to page 11

PERFORMING AN UV-BONDING IN CASE OF HIGH OR MEDIUM-VISCOSITY ADHESIVES 7B) Apply the adhesive before placing the parts to be bonded. 8B) Place firmly the pieces to be bonded with the help of supports, suction cups or templates, useful during the pre-bonding phase in order to avoid even the littlest moves. IN CASE OF THIXOTROPIC ADHESIVES 7C) Our FIXGLASS UV GEL is a highly viscous adhesive, which allows to be used for vertical bonding, given that it doesn’t drip. 8C) Place firmly the pieces to be bonded with the help of supports, suction cups or templates.

Open the catalog to page 12All Logli Massimo Spa catalogs and technical brochures

-

Intro

25 Pages

-

Systems for glass balustrades

101 Pages

-

Systems for outdoors

51 Pages

-

Systems for glass partitions

65 Pages

-

Glass holders and point fixings

71 Pages

-

Steel systems for sliding doors

63 Pages

-

Aluminium systems for sliding doors

151 Pages

-

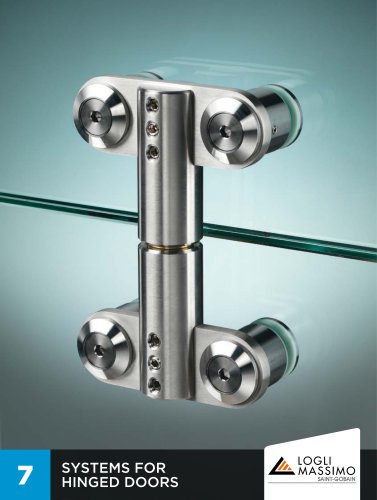

Systems for hinged doors

121 Pages

-

Pull handles and knobs

59 Pages

-

Systems for shower partitions

221 Pages

-

Systems for UV bonding

81 Pages

-

Accessories for glassworks

84 Pages

-

Analytical index

12 Pages

-

Defender Collection 2021

136 Pages

-

MECCANOGLASS

28 Pages

-

CRISTAL

22 Pages

-

LA PENSILINA

12 Pages

-

Single-point fixings

12 Pages

-

REGTER

8 Pages

-

Shower kit

88 Pages

-

DQ Carré Noir

20 Pages

-

LM Doccia

16 Pages

-

Doccia UV

16 Pages

-

Pivot-Up Square

16 Pages

-

Adhesive seals

8 Pages

-

Imbotte

16 Pages

-

Glass partitions

32 Pages

-

LMGW Series

24 Pages

-

LM series no glass cut out

18 Pages

-

LM Series

34 Pages

-

LMS Series

24 Pages

-

LMTR Series

26 Pages

-

Silicones & sealants

16 Pages

Archived catalogs

-

Doccia Flat

20 Pages