Catalog excerpts

Your New Zeatihj Experience Leadcom Seating

Open the catalog to page 1

Leading public seating manufacturer that helps makes your business unique! Leadcom Seating is a leading specialist public seating manufacturer offering a huge range of auditorium and cinema seating, waiting area seating, lecture hall seating, church seating and coach and bus seating. Unlike many other seating manufacturers who simply just assemble seating components outsourced from other suppliers, 99% of Leadcom’s products are expertly tooled in our own fully-fitted workshops. And this is only after raw materials have arrived and been tested in our own industry-dedicated testing facility....

Open the catalog to page 4

In what aspects Leadcom Seating makes the difference from all the others? 2 Yearly production capacity – ONE MILLION seats High flexibility for lastminute order 1 Rich manufacturing resources – 120,000 sqm of full range workshops, 3 manufacturing facilities Full package of custom project management service provided by experienced sales teams Unparalleled custom design capabilities – strong engineer team Quick and efficient response from professional staff every step of the way Impressive delivery time – guaranteed by second-tonone production capac

Open the catalog to page 5

A: Office Building B: Reception Hall A: Punching Workshop B: Hydraulic Machine C: NC Punching Machine D: NC Punching Machine > Production capacity -1,000,000 seats/ year with annual raising speed of 10%-20%. > Over 850 people employed. > Strong engineer team (22 people).

Open the catalog to page 6

MANUFACTURING FACILITIES Our manufacturing machinery features only the most up-to-date technology, with advanced techniques utilised for every step of the production process. Every part of your chair - back, seat, armrests, leg, beam, writing table, footrest, cover as well as other components and accessories needed for a solidly comfortable seat are expertly-tooled on-site in our fully-fitted workshops. Each component is manufactured individually and then assembled under strict supervision and control. In this way, we not only ensure product quality while at the same time keeping costs to a...

Open the catalog to page 7

MANUFACTURING FACILITIES We continually recruit, develop and further motivate our skilled and talented employees. Every two weeks we offer all employees training and educational courses on the effective use of technology and tools, work safety, ethics, laws and regulations. These are provided to ensure our staff is not only well-trained for the working process, but at the same time have the opportunity to contribute to, and benefit from, our growth. Continuous improvement is a very important part of our operating culture, and we continually invest our people through career advancement...

Open the catalog to page 8

MANUFACTURING FACILITIES We don’t like untidiness and chaos! Everything from raw material sourcing to finished products is organised and correctly-stored at our manufacturing facilities following established lean techniques and efficiency principles. With Leadcom Seating, you can be assured that your order is in good hands and under total control.

Open the catalog to page 9

QUALITY CONTROL At Leadcom Seating, the quality control department adheres to strict quality standards on every single component during every stage of the production of each product. We have established a system of recognised quality control according to the international ISO9001 and ISO14001 quality management system standards with quality control inspections during all phases of production. Before the production process even begins, we select the finest materials for our products. Our quality control inspectors make sure that everything from raw materials to finished products meets and...

Open the catalog to page 10

CORE BUSINESS - solutions for auditoriums, cinemas, waiting areas, lecture halls, coaches & buses Cinema Recliner Auditorium Seating Lecture Hall Seating Cinema Seating Waiting Area Seating

Open the catalog to page 12

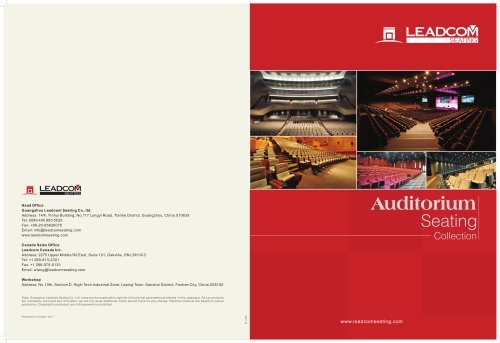

AUDITORIUM SEATING TOP SELLERS

Open the catalog to page 13

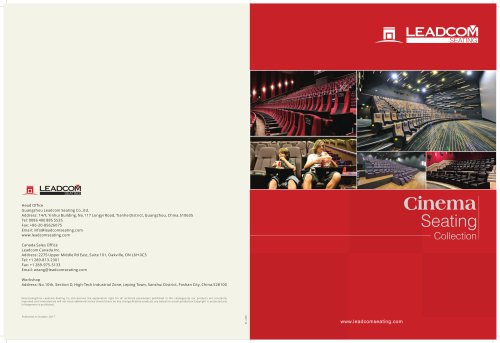

CINEMA SEATING TOP SELLERS

Open the catalog to page 14

CINEMA RECLINERS

Open the catalog to page 15

WAITING AREA SEATING TOP SELLERS

Open the catalog to page 16

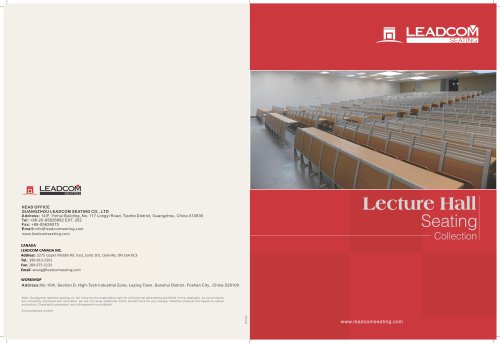

LECTURE HALL SEATING TOP SELLERS

Open the catalog to page 17

COACH & BUS SEATING TOP SELLERS CIVIC PIONEER CIVIC EXPERT CIVIC STANDARD

Open the catalog to page 18

How your chairs be equipped Plastics — 100% new polypropylene materials, completely eco-friendly, recyclable and fully durable (not easily broken). Cushion (foam materials) — raw materials are imported from BASF Germany that are capable of delivering years of service while at the same time providing deluxe seating comfort. Wood works — all woodwork goes through a seven-layer painting process to provide a perfect finish that does not tarnish easily. Quality powder coating finish for metal parts — all metal parts undergo a strict and higher-than-standard processing before being...

Open the catalog to page 19

OUR SALES MARKETS We have five dedicated international sales teams for your seating projects, responsible for five main international geographic divisions: • Africa, middle east • North & South America • Europe • Asia & Oceania • Canada All queries are directed by our sales support representatives to the appropriate international sales team according to the country where the project is located. Each sales team is comprised of a divisional manager, sales manager and sales representatives, responsible for their own specific international region. The NO. 1 supplier in China market excel at...

Open the catalog to page 22

Who are involved with your project? Customer service Sales team PMC – sourcing, manufacturing, packing, storage Engineer team Before Production Seat planners Engineer team Technical team Technical team After sales service

Open the catalog to page 23

PRODUCT PROCESSING Hardware processing PUNCHING AND FORMING IN PUNCHING WORKSHOP ROBOT WELDING INTRODUCED FROM JAPAN WITH CARBON DIOXIDE AS SHIELDING GAS ELECTROSTATIC COATING DEGREASING, DERUSTING PHOSPHATING, PASSIVATING

Open the catalog to page 24

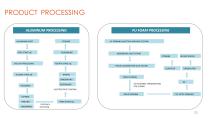

PRODUCT PROCESSING ALUMINUM PROCESSING ALUMINUM SHEET PU FOAM PROCESSING PU FORMING INJECTION MACHINE TESTING ASSEMBLING LINE TESTING STORAGE MOLD CLEANING AND GLUE FILLING QUALIFIED CHROMATING DEGREASING MOLD CLOSING 45-55 DEGREE PRESERVATION FOR 3-5MIN. ELECTROSTATIC COATING MOLD OPENING TAPPING DRILLING DEBURRING machinery processing

Open the catalog to page 25All Leadcom Seating catalogs and technical brochures

-

Leather swatch

8 Pages

-

Leadcom_Colour_Swatch_2016

6 Pages

Archived catalogs

-

Leadcom Seating Cinema Seating

10 Pages