Website:

KESSEL

Website:

KESSEL

Group: Kessel

Catalog excerpts

Hybrid drainage systems for gravity sloped wastewater pipes For industrial and domestic applications

Open the catalog to page 1

Constant running of a standard lifting station even with gravity sloped drainage. Why? Lifting stations are often installed as a safety measure even though gravity sloped drainage is available. The disadvantage is that these systems must pump every single litre of collected wastewater. This leads to constant operation of the pumps, high energy usage, wear and tear on the system as well as nuisance noise - with the new KESSEL Hybrid Lifting Station, all these problems are solved. The Pumpfix and Ecolift XL Hybrid Lifting Stations offer safe and reliable protection against backwater and come...

Open the catalog to page 2

System concepts and system advantages of the Hybrid Lifting Stations page 04 - 05 Systems for industrial applications Backwater lifting station Product information Page 06-07 Installation example Page 13 Systems for domestic applications Backwater pumping station Pumpfix F Komfort page 14-19 Product information Page 14-15 Backwater inspection Planning made easier page 22 - 23 Scan this QR code to directly view the corresponding product video. SmartSelect simply makes planning easier - calculation module for lifting WORTH KNOWING

Open the catalog to page 3

The New Hybrid Lifting Station Family We have made the direct connection safe and reliable Normal mode: Water drains with gravity Backwater: Backwater flap is closed Pump activates, wastewater is discharged Pumpfix and Ecolift XL The Pumpfix and Ecolift XL Hybrid Lifting Stations use natural gravity wastewater flow to the sewer during normal operation. The flap closure system automatically activates only during backwater and the pumping system then pumps any collected wastewater into the surcharged sewer. This allows drainage fixtures connected to the system to be used even during times of...

Open the catalog to page 4

The direct connection saves energy A standard lifting station must collect every litre of incoming wastewater and pump it into the sewer which is a constant use of valuable energy. The KESSEL Hybrid Lifting Stations function differently - they only activate when they are actually needed. This makes them much more ecological as well as economical systems - reducing energy and maintenance. The Pumpfix and Ecolift XL systems offer significant energy savings as well as reduce service and maintenance costs. The direct connection is quiet Despite modern mechanical components and noise insulation,...

Open the catalog to page 5

Product description / Product advantages of the Ecolift XL Hybrid Lifting Station for industrial applications ENGINEERING SYSTEM BASE For indoor / free standing installation, for installation in a concrete floor, or outdoor underground installation in combination with the engineering systems chamber SAFETY / RELIABILITY Pneumatic level sensing and alarm sensor offer twice the reliability INTEGRATED CLOSURE VALVE With safety lock to prevent accidental closure PRESSURE OUTLET CONNECTION Quick-release, no tools required INLET / OUTLET Up to size Ø 160 mm GROUNDWATER RESISTANT New chamber can...

Open the catalog to page 6

SmartSelect simply makes planning easier - calculation module for lifting stations at smartselect.kessel.com ENGINEERING SYSTEMS CHAMBER For use in combination with the Ecolift XL Hybrid Lifting Station for installation in the concrete slab or outdoors underground CHAMBER COVERS Available in a stainless steel class A/L15 (tileable or not tileable) or in load classes B and D VERTICALLY ADJUSTABLE UPPER SECTION Available with Ø 600 mm or Ø 800 mm diameter with optional waterproofing connection flange ADDITIONAL INLET CONNECTIONS Three areas are available for easy on-site connection of conduit...

Open the catalog to page 7

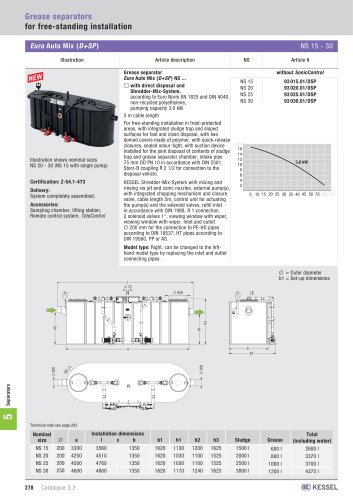

Hybrid Lifting Stations Backwater lifting Station Ecolift XL for free-standing installation Engineering system base Ecolift XL Mono / Duo Illustration and dimensioned drawing Products Voltage Article description Engineering system base with welded chamber ring Backwater Lifting Station Ecolift XL Mono / Duo for wastewater with sewage and wastewater without sewage For free-standing installation in frost-protected rooms Inlet / outlet Ø 160 mm Mono version with one SPF pump and Comfort Plus control unit 1 with one motor-driven backwater flap for wastewater without sewage 2 with two...

Open the catalog to page 8

Hybrid Lifting Stations Backwater lifting Station Ecolift XL for minimum installation height Engineering system base Ecolift XL Mono / Duo Illustration and dimensioned drawing Products Voltage Article description Duo version with two SPF pumps and Comfort Plus control unit 3 with one motor-driven backwater flap for wastewater without sewage 4 with two motor-driven backwater flaps for wastewater with sewage Mono version with one SPF pump and Comfort Plus control unit 1 with one motor-driven backwater flap for wastewater without sewage 2 with two motor-driven backwater flaps for wastewater...

Open the catalog to page 9

Hybrid Lifting Stations Backwater lifting Station Ecolift XL for installation depth up to 5m Engineering system base Ecolift XL Mono / Duo Illustration and dimensioned drawing Products Voltage Article description Engineering system base with welded chamber ring Backwater Lifting Station Ecolift XL Mono / Duo for wastewater with sewage and wastewater without sewage For outdoor underground installation, or installation in a concrete floor in combination with an engineering system chamber Inlet / outlet Ø 160 mm Mono version with one SPF pump and Comfort Plus control unit 1 with one...

Open the catalog to page 10

Hybrid Lifting Stations Engineering system chamber System chambers Ø 1000 with access opening Ø 600 / Ø 800 mm Illustration and dimensioned drawing Products Installation depth mm Article description Engineering system chamber for combination with the engineering system base Ecolift XL made of polyethylene with access opening Ø 600 mm Upper section with round cover, made of cast iron 1 Class A/B 2 with access opening Ø 800 mm Upper section with cover, made of stainless steel 3 Round, class K 3 4 Square, class A/L 15, not tileable, non-slip 5 Square, class A/L 15, tileable Covers surface...

Open the catalog to page 11All KESSEL catalogs and technical brochures

-

Backwater protection

12 Pages

-

Backwater Valve

8 Pages

-

Tailor-made

24 Pages

-

Aqualift F XXL 400 V – 60 Hz

12 Pages

-

Pump technology

58 Pages

-

Hybrid drainage systems

24 Pages

-

Separators

57 Pages

-

Drains-and-Channels

107 Pages

-

Lifting-stations

69 Pages

-

Hybrid-lifting-stations

19 Pages

-

Backwater-Valves

41 Pages

-

Catalogue3.2

326 Pages

-

Euro Auto Mix & Pump (PV+S )

1 Pages

-

Euro Mix & Pump (M+S )

1 Pages

-

Euro Auto Mix (D+SP )

1 Pages

-

Euro Mix (D+S )

1 Pages

-

Euro Standard (D )

1 Pages

-

Catalogue 3.1

310 Pages

-

Drains and channels

112 Pages

-

lifting stations

64 Pages

-

Hybrid lifting stations

20 Pages

-

Backwater protection

36 Pages

-

Brochure Ecolift

8 Pages

-

Brochure "Staufix"

8 Pages

-

EasyClean Grease Separators

8 Pages

-

Aqualift F Compact

6 Pages

-

Separators

30 Pages

-

Parking deck drains

18 Pages

-

Shower channels

15 Pages

-

Bathroom drainss

15 Pages