Website:

KERAKOLL

Website:

KERAKOLL

Catalog excerpts

Breaking news! GeoLite® is here GeoLite : he first geo-mortar for t monolithic concrete repair ® The technical and performance limits of popular cement and chemical-additive based mortars and the complex, layered systems used to repair concrete are a thing of the past, now that GeoLite®, the revolutionary, eco-friendly, mineral geomortar, can passivate, repair, finish and protect deteriorated concrete in a single solution. Result: naturally stable repairs which crystallize with the concrete to form a monolithic element with a durability akin to mineral rock.

Open the catalog to page 1

What is GeoLite®? GEOLITE® IS THE DEFINITIVE SOLUTION TO REPAIRING CRACKS AND DEBONDING ONCE AND FOR ALL GeoLite® is the new range of mineral geomortars resulting from Kerakoll's research into innovative GreenBuilding materials for use in the eco-friendly restoration of concrete. GeoLite® means innovative mineral products that are easy to apply, and which provide the definitive solution to the limits of traditional cement-based, modified-polymer mortars. GeoLite® repairs concrete guaranteeing a monolithic repair with a high level of natural dimensional stability, and the same kind of...

Open the catalog to page 2

GeoLite®: mineral elements only to guarantee rock-like durability China Clay and Natural Bauxites Kerakoll Geolegante® (geo-binder) Kilning Mineral, monolithic Restoration Silicates and amorphous Aluminates Zirconia Cristallina® (Crystalline zirconium) Inert fine silicates Micronized clinker Alkaline Mineral Salts Zirconia Cristallina® (Crystalline zirconium) Kerakoll Geolegante® (geo-binder) Fine Siliceous Sand (grain size 0 - 0.5 mm) Micronized Pure White Carrara Marble Carbonate (grain size 0 - 0.3 mm) Quartz Sand (grain size 0 - 0.4 mm) KERAKOLL’S GROUNDBREAKING NEW GEOLEGANTE®...

Open the catalog to page 3

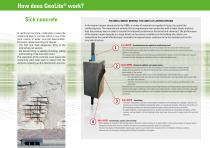

How does GeoLite® work? Sick concrete In reinforced concrete, carbonation causes the reinforcing steel to corrode, which is one of the main causes of wider concrete deterioration. Corrosion causes two things to happen: - the first and most dangerous thing is the diminishing rod section;. - the second thing is spalling (cracking, pitting and breaking of the concrete cover). The separation of the concrete cover leaves the reinforcing steel wide open to attack from the elements, speeding up the deterioration process. POLYMER-CEMENT MORTAR: THE LIMITS OF LAYERED REPAIRS In the layered repairs...

Open the catalog to page 4

GeoLite® the first ever crystallization-based monolithic restoration product for concrete: passivates, reconstructs, corrects imperfections and protects Passivates GeoLite® provides perfect barrier protection of reinforcing bars thanks to the exclusive rheology and extra-fine grain size, doing away with the need for the protective polymer-cement coatings currently used. The non-standard reserve basicity of Kerakoll's new geo-binder gives the steel very high electrochemical passivating values, and thus fully certified oxidation-protection of the reinforcing bars, the first ever of its kind....

Open the catalog to page 5

EN 1504-compliant GeoLite® GeoLite®: three different quality marks, three times as safe. GEOLITE®: THE ONLY EN 1504-COMPLIANT MONOLITHIC REPAIR All the materials to be used in the maintenance, repair, strengthening and protection of existing reinforced concrete structures must be CE-marked in accordance with European regulation EN 1504. GeoLite® is the world's first range of geo-mortars to obtain three different CE marks: - GeoLite® meets every requisite of EN 1504-7 (passivation of reinforcing bars), EN 1504-3 (structural repair) and EN 1504-2 (protection); - GeoLite® Magma meets every...

Open the catalog to page 6

GEOLITE®: SIMPLIFIES REINFORCED CONCRETE REPAIR AND PROTECTION SPECIFICATIONS, ACCORDING TO EN 1504-9 GeoLite® can be used to carry out repairs based on the Principles and Methods for repair and protection laid down in European standard EN 1504-9. The monolithic nature of the repair guaranteed by GeoLite® makes the job of architects and engineers much simpler when it comes to drawing up specifications; this in turn guarantees the easier and more effective execution of the reinforced concrete maintenance job, in accordance with applicable regulations. In particular, with GeoLite® the...

Open the catalog to page 7

GeoLite®: geo-mortar with setting times to suit the application GEOLITE®: THE FIRST EVER RANGE OF R4 GEO-MORTARS WITH CUSTOMIZABLE SETTING TIMES Kerakoll's research team has developed 2 versions of the groundbreaking GeoLite® range: thixotropic with three mixable setting times (80, 40 and 10 minutes) and fluid with two setting times (60 and 20 minutes). GeoLite® adapts to the needs of the building site, with a setting time to suit the type of job and climatic conditions making sure you always get the workability you need without altering the technical properties of the product (Structural...

Open the catalog to page 8

GeoLite®: innovative, safe and eco-friendly technology GEOLITE® MICROSILICATO REGENERATES CONCRETE STRUCTURES BY CRYSTALLIZATION Concrete is a compact material with pores and micro-pores which are invisible to the human eye. GeoLite® MicroSilicato is the revolutionary new geo-paint that contains geo-active silicate micro-particles which penetrate the pores in the concrete; interstitial crystallization then occurs with the cementitious matrix, sealing off the pores and protecting them from environmental chemical aggression. GeoLite® MicroSilicato protects concrete from carbonation and blocks...

Open the catalog to page 9

GeoLite® on site Layered system and technologically obsolete products, more than 5 products, 5 application steps, 6 days work PASSIVATING MORTAR Application of anti-corrosion, two-component cementitious mortar to protect reinforcing bars ADDITIVES Preparing the polymermodified mortar with added seasoning additives or retardants LARGE-GRAIN MORTAR Application of fibrereinforced, modifiedpolymer mortar with controlled shrinkage to rebuild the concrete FINE-GRAIN MORTAR Application of twocomponent cementitious mortar as a concrete finish layer 6th day ELASTOMERIC PAINT Application of...

Open the catalog to page 10All KERAKOLL catalogs and technical brochures

-

Resyflex® CP3

2 Pages

-

Biocalce® Marmorino

3 Pages

-

BioGesso® Stucco mangiaVOC®

3 Pages

-

Biocalce® Intonachino Fino

3 Pages

-

Biocalce® Muratura

3 Pages

-

Isobuild® Eco Block

3 Pages

-

Keradecor Zinkover

2 Pages

-

Keradecor Prontofix

2 Pages

-

Kerakover Acrilsilossanico

2 Pages

-

Kerakover Acrilex Fondo

2 Pages

-

Rasobuild® Eco Top Fino

3 Pages

-

Kerabuild Ghiaia

1 Pages

-

Geolite_1220

4 Pages

-

Fugalite® Bio Parquet

7 Pages

-

Biogel® No Limits®

3 Pages

-

Tapetex Plus

1 Pages

-

Bioscud

6 Pages

-

Aquaform OD - OD Plus

3 Pages

-

Aquastop Green

7 Pages

-

Fugalite® Bio ParqueT

5 Pages

-

Warm Collection

52 Pages

-

Fugabella® Color

24 Pages

-

Biogel® Gel Adhesives

20 Pages