Catalog excerpts

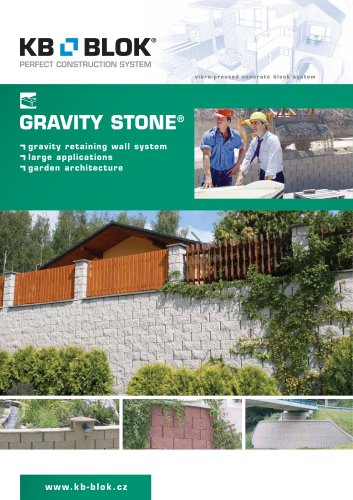

vibro-pressed concrete block system GRAVITY STONE® gravity r etaining wall system lar ge applications gar den ar chitectur e

Open the catalog to page 1

GRAVITY STONE ® - large applications Introduction The GRAVITY STONE® system has been designed for construction of gravity retaining walls. The system is composed of several concrete blocks that may be combined in many retaining wall variants. Block joints are dry: blocks in a single course are lock-joined, while two neighbouring courses are connected by plastic pins. The inner space of the wall is filled by a suitable fill material. The blocks of the system are made on production facilities purchased in the USA, by vibro-pressing technology with low water coefficient. High concrete strength...

Open the catalog to page 2

vibro-pressed concrete block system Benefits of the GRAVITY STONE ® system Aesthetics Retaining walls made of the GRAVITY STONE® system show high aesthetic value. Different colours of blocks as well as different surface finishing options of the facing block may be selected when designing the wall. Smooth surface or split facing blocks are available as well as seven basic colour options. The individual blocks allow for different wall shapes as regards ground plan (curved, bent walls, etc.) as well as vertical configuration. The main aesthetical benefit of the walls is seen in breaking up...

Open the catalog to page 3

GRAVITY STONE ® - large applications Geologic survey Prior to commencement of the construction, a geologic survey must be made the scope and cost of which must correspond with the size and complexity of the construction. It is not recommended to commence the project and the construction itself without geologic survey. Preliminary wall design The suitable wall type must be decided upon within the preliminary wall design. GRAVITY STONE® system walls may be divided into two groups: modular and reinforced. for lower heights than reinforced walls. A dug-in modular wall is economically more...

Open the catalog to page 4

vibro-pressed concrete block system Facing block The facing block may be made in seven basic colours and the following surface finish options: smooth surface and split block. It is used as a front face block in both modular walls (made of blocks only) and reinforced walls (by geogrids). The approximate weight of the block is 33 kg. Anchoring dowel The anchoring dowel connects the facing block and the anchoring element, thus creating the necessary structural depth of a single anchor. The dowel is made in natural colour only. The approximate weight of the block is 24.5 kg. Anchoring element...

Open the catalog to page 5

GRAVITY STONE ® - large applications Anchoring principle of the GRAVITY STONE® system The individual elements of the system are interconnected into different anchoring configurations in order to provide for the required weight of the gravity retaining wall. The connection is of the grove and tongue type moulded in each block. This is a quick and easy connection that does not require any tools, mortar or bonding agent. The three basic anchor configurations are the following: Single anchor This configuration consists of a facing block, an anchoring dowel and an anchoring element. The overall...

Open the catalog to page 6

vibro-pressed concrete block system Assembly and filling of GRAVITY STONE® walls GRAVITY STONE® walls are built by dry assembly, which is easier and faster than construction of traditional walls using mortar. Wall assembly is easy and it may be done even by non-qualified personnel under supervision of an experienced and trained foreman. Connecting pins Each facing block, special facing block 400 and facing block 95 has two T-shaped openings on the top side. Plastic connecting pins are inserted into the openings as shown in the picture. The pins are inserted perpendicularly to the face of...

Open the catalog to page 7

GRAVITY STONE ® - large applications Right angle bent walls The GRAVITY STONE® system also makes it possible to build walls bent in right angle. Construction of such angles requires proceeding in accordance with the following recommendations regarding the correct structure and the aesthetic layout of inner and outer corners. Inner corners The corner bond is crucial when constructing inner corners. The figure shows an example of an inner corner with a single anchor. Bond of a wall of an inner corner with a single anchor Reinforcement direction Extension of a geogrid in the next reinforcement...

Open the catalog to page 8

vibro-pressed concrete block system Geogrid in 2nd reinforcement direction to be positioned in this extent in the next bed joint Outer corners with geogrids are reinforced so that there is always just one geogrid in the bed joint. This means that the geogrid that overlaps with the perpendicular geogrid in the corner should be positioned in the next bed joint. The figure shows a diagram of an outer corner reinforced by geogrids. Geogrid in 1st reinforcement direction reaches as far as the end of the wall Outer corner reinforced by geogrids Note: It is recommended to construct vertical...

Open the catalog to page 9

GRAVITY STONE ® - large applications Convex walls The minimum radius of a convex wall is given by the angle of taper of the rear section of the sides of the facing blocks. The angle is approximately 8.5°. This means the minimum radius is approximately 1.5 m. With convex walls, some anchoring dowels and elements must be left out and some lock joints must be removed in some cases. Taper angle of the rear section of facing blocks and maximum angle of rotation of adjacent blocks Minimum radius of a convex wall Reinforcement direction Reinforcement direction Overlapping geogrids to be separated...

Open the catalog to page 10

vibro-pressed concrete block system The process of building a wall: 1 Make an excavation or a dig in the slope at the location of construction of a retaining wall. Lay down and properly compact the gravel pad used as the wall foundation. Install a drainage pipe in the lowest point of the gravel pad. A vibration plate is used for compaction the gravel pad – see figure. The compacting is done by three passes over the surface of the pad. Check whether the upper face of the gravel pad is level before installing the first course of blocks. Installation of the first course Preparation of the face...

Open the catalog to page 11All KB BLOK catalogs and technical brochures

-

catalogue of colours

139 Pages

-

Geostone

28 Pages