Catalog excerpts

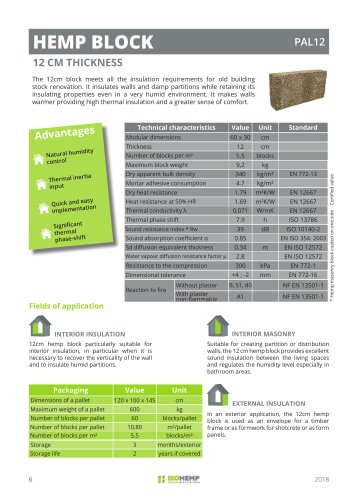

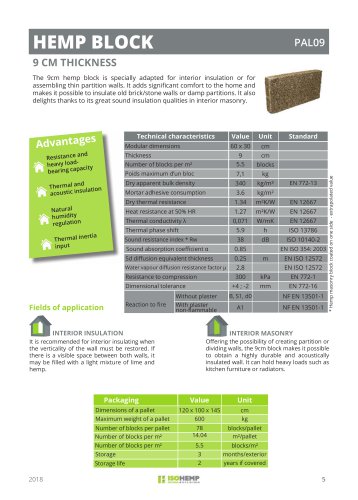

Specifications – IsoHemp Masonry Masonry in IsoHemp blocks Generality The masonry will be installed so that it is straight and plumb, in accordance with the rules. They must comply with all the regulations and standards (including the Eurocodes). The stability plans define the characteristics of the masonry elements (blocks) as well as the mortar. These must be scrupulously respected. The mortar used on site is subject to approval by the architect and the design office. The technical data sheets for the masonry units and mortar will be sent to the architectural and stability offices for approval, at least 15 working days before they are used. The walls will be joined together by harpooning the elements. If this is not possible, a strap connection will be used, to be approved by the design office. The elements must be assembled (or matched) with alternating vertical joints (overlapping) to ensure that the masonry is monolithic. The masonry must be protected from the weather as it is built. Masonry with glued hemp concrete blocks Hemp blocks are made in Belgium. They are self-supporting masonry units but cannot play a structural role. They are made from hemp shives and a mixture of air and hydraulic lime. The hemp shives have a grain size of between 2 and 20 mm. The concrete is made up of +/- 80% hemp shives, the remainder being lime and the water used to hydrate the binder. The product is molded, pressed, hardened and air-dried without energy input. The blocks are 60 cm long and 30 cm high, 36 cm wide blocks are 20 cm high and 30 cm and 36 cm wide blocks have vertical mortise and tenon joints. They are manufactured in variable widths ranging from 7.5 cm to 36 cm. The dry bulk density of the blocks is between 306 and 374 kg/m³. Compressive strength greater than 0.22 MPa. Thermal conductivity λ is 0.071 W/mK. The dimensional tolerances of the blocks are +4/-4 mm on the length and width and +1/1.5 mm on the height in accordance with standard NBN-EN-772-16. The manufacturer has an ATG on the masonry elements

Open the catalog to page 1

Specifications – IsoHemp Masonry Installation must strictly comply with the manufacturer's instructions. The contractor is deemed to have read the manufacturer's documents specifying the installation technique, such as "the installation guide". The architecture and design offices may require the contractor to undergo on-site training with the manufacturer, who will provide a certificate of attendance and specify the persons present. The hemp blocks are glued together using the adhesive mortar prescribed by the manufacturer. The first bed of blocks should be laid in a full bath of...

Open the catalog to page 2

Specifications – IsoHemp Masonry Walls thickness 7,5 cm ; QP m² Characteristics: see architectural and stability plans and manufacturer's specifications. Wall thickness 9 cm ; QP m² Characteristics: see architectural and stability plans and manufacturer's specifications. Walls thickness 15 cm ; QP m² Characteristics: see architectural and stability plans and manufacturer's specifications. Walls thickness 20 cm ; QP m² Characteristics: see architectural and stability plans and manufacturer's specifications. Walls thickness 25 cm ; QP m² Characteristics: see architectural and stability plans...

Open the catalog to page 3

Specifications – IsoHemp Masonry Doubling an existing wall Hemp blocks should be used to line an existing wall, either from the inside or the outside. They should be assembled in accordance with the above specifications. A space of +/- 3 cm must be left between the existing wall and the masonry made of hemp blocks. This space will be filled progressively, primarily with hemp concrete aggregates. However, a mixture of hemp shives, hydraulic lime and air lime can also be made on site using a lime mixture preformulated in the factory specifically for this purpose and shives delivered in bulk....

Open the catalog to page 4

Specifications – IsoHemp Masonry In the case of a metal or wooden structure, the masonry of hemp blocks is an infill between the posts and beams. These structural elements are encased using U blocks, which are laid vertically around the columns and horizontally around the beams. For beams that are higher than the U-blocks, the latter are raised using specially adapted elements. The Isohemp masonry will be connected to the structure using angle-type anchors in accordance with the structural stability study. Walls thickness 30 cm ; QP m² This item includes drilled blocks and U-blocks. Walls...

Open the catalog to page 5All ISOHEMP catalogs and technical brochures

-

IsoHemp Hemp block

3 Pages

-

Catalogue 2022 EN IsoHemp

32 Pages

-

Product catalogue

24 Pages

-

Folder - Hempcrete blocks

4 Pages

-

Folder - Hempro system

2 Pages