Catalog excerpts

LOAD BEARING PROFILE LG153-840

Open the catalog to page 1

Load Bearing Profile LG 153-840 is mainly used for roof structures with large spans as support for thermal and hydro-insulation.It can be used also as concrete form works. The arrow indicates the polyester 15 ym protected side. Note! Load bearing profiles are delivered with the narrow flange oriented upward. Please check the correct position of the profile before installation. SERVICES AND OPTIONS Steel sheet perforation Standard perforation percentage is 15%. The perforated holes are 3 mm diameter, these being distributed on an equilateral triangle path with 7,4 mm side. Because of the...

Open the catalog to page 3

864 840 No. Thickness Weight Limit yield point Tensile strength Zinc Coating nominal core Dimensioning tables according to EN 1993-1-3. I.Ultimate limit state (ULS; Q). Compare design load where safety factors must be included to table values (1.ULS). 2.Serviceability limit state. Deflection limit f = L/150 (SLS; Qj. Serviceability limit state safety factors = 1.0. 3Serviceability limit state. Deflection limit f = L/200 (SLS; Qj. Self-weight of the sheet has been taken into account with 1.35 safety factor 4.Serviceability limit state. Deflection limit f = L/300 (SLS; Qj. Continuous uniform...

Open the catalog to page 4

Middle support width: 160 mm Thick Span lenght L [m] Middle support width: 160 mm Thick Span lenght L [m]

Open the catalog to page 5

Maximum width [mm] 864 840 No. Weight Limit yield point Tensile strength Dimensioning tables according to EN 1993-1-3. Compare design load where safety factors must be included to table values (1.ULS). Serviceability limit state safety factors = 1.0. Self-weight of the sheet has been taken into account with 1.35 safety factor Continuous uniform load in [kN/m2]. I.Ultimate limit state (ULS; Q). 2.Serviceobility limit state. Deflection limit f = L/150 (SLS; Qj. 3Serviceability limit state. Deflection limit f = L/200 (SLS; Qj. 4Serviceability limit state. Deflection limit f = L/300 (SLS; Qj....

Open the catalog to page 6

3. Span structure Material factor End support width: Middle support width:

Open the catalog to page 7

LOAD BEARING SHEET The upper side is 10 µm epoxy paint protected while the lower side (exposed) is protected with polyester paint 15 µm. 1. Lower side polyester paint 15 µm 2. Pretreatment 3. Galvanizing 4. Steel 5. Galvanizing 6. Pretreatment 7. Primer coat 8. Epoxy paint 10 µm The designer must take into account the exposed side when choosing the accurate installation of load bearing profile. Due to unexposed upper side, the load bearing profile is not affected by the UV or weather conditions but can be affected by the internal conditions such as production lines, condense or contact with...

Open the catalog to page 8

INSTRUCTIONS - LOAD BEARING PROFILE LG153-840 CRANE UNLOADING For lifting, the packages must always be fixed in at least two points at a certain distance between them, but not less than half of the packages length. Lifting must be performed with straps made of synthetic fibre (nylon), having the width of 10 cm or more, so that the load is distributed on the straps and does not cause panel deformation. Do not use chains or sharp metallic accessories ( see fig. 1) LIFTING DEVICE NYLON STRAPS SECURITY ELEMENTS Adequate spacers must be used under or above the package, made of solid and robust...

Open the catalog to page 9

INSTRUCTIONS - LOAD BEARING PROFILE LG153-840 STORAGE The packages must be stored at a distance from the ground of at least 20 cm, both in the storehouse, as well as at the site. The materials must be stored on dry wooden supports, longer than the width of the package and with an adequate distance between the supports (depending on the length of the package). Also, three packages shall be stacked, without exceeding this number. The packages supplied by Isopan are packed according to these rules. We recommend to store the panels in the original package. It is not recommended to store the...

Open the catalog to page 10

The panels must be handled according to the occupational safety standards, using the adequate protection means (gloves, protection clothes, coveralls etc.). The manual handling of a panel must be performed by lifting the panel from the package towards its side, avoiding the contact with the panel underneath. Avoid translation movements in case of a contact between panels (as a result of these movements, the panel surface can be scratched). (see fig. 3) INSTALLATION The staff in charge with the panels installation must be qualified and must have the correct technical knowledge in order to...

Open the catalog to page 11

www.isopan.com ITALY REGISTERED AND ADMINISTRATIVE HQ Via Augusto Righi 7 37135 Verona | Italy T. +39 045 8088911 ISOPAN SPA Verona | Italy T. +39 045 7359111 Frosinone | Italy T. +39 07752081 WORLD ISOPAN IBERICA Terragona | Spain T. +34 977 52 45 46 ISOPAN EST Pope$ti Leordeni | Romania T. +40 21 3051 600 ISOPAN DEUTSCHLAND GmbH OT Plotz | Germany T. +49 3460 33220 ISOPAN RUS Volgogradskaya oblast’ | Russia T. +7 8443 21 20 30 ISOCINDU Guanajuato | Mexico T. +52 1 472 800 7241 SALES COMPANIES ISOPAN FRANCE Merignac | France T. +33 5 56021352 ISOPAN MANNI GROUP CZ Praha | Czech Republic...

Open the catalog to page 12All ISOCINDU SA DE CV catalogs and technical brochures

-

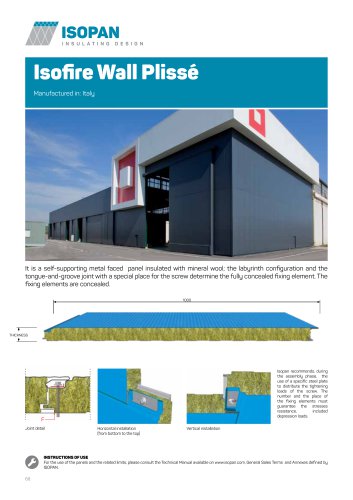

isoparete_en_0

2 Pages

-

ISOPAN ISOLITE

8 Pages

-

ISOPAN_LEAF_BROCHURE_EN_LOW

3 Pages

-

ISOPAN_ZOOTECNIA_EN_LOW

4 Pages

-

ISOPAN_LEED_BCC_V4

2 Pages

-

LEAF_DATASHEET_REV1_ENG

2 Pages

-

MANNI_GROUP_WINE_AND_STEEL

16 Pages

-

ISOFARM_REV0

20 Pages

-

ISOPAN_ARK_WALL_GAMMA_COLORI

24 Pages

-

General Catalogue

60 Pages

-

Brochure isocindu

4 Pages