Catalog excerpts

Specifying Art Diffusion Division 6 (6400 Architectural Millwork) Interlam has a standard lead time of 1 to 4 weeks for the majority of Art Diffusion Carved MDF wall panel orders. Specific lead times are determined upon receipt of both the deposit and approved shop drawings. Lead times are based on a “first come first served” basis and are solely dependent upon our current work load. Interlam does not charge nor accept additional charges to rush orders. All orders will be manufactured as fast as possible in the order they are received. The Art Diffusion Carved MDF wall panel product offers the customer an extremely broad variety of patterns, materials, finishes and installation choices. In order to translate a customer requirement into an accurate product specification, it is important to understand all of the product options and terms used to describe these options. Product specification terms and options are discussed below along with helpful illustrations. It is important to first select a core material based on specific project needs, such as contribution towards "Leed" credits, FSC Certified fibers with COC, Class A fire rating, radius applications, interior or exterior applications, formaldehyde emissions or moisture resistance. Core materials are available to fit most special needs such as radius or serpentine installations, opaque wall dividers or exterior applications. Not all core materials are available in all sizes, finishes and or patterns. Consult the specific pattern page to determine available thickness and sheet size for each individual core. Lead times will be increased if a non-standard sheet size or thickness is required for any given job. Flame Spread Performance of MDF / IDF Wood Panels: Unless otherwise stated, Interlam’s IDF or Carved MDF wood panels are not certified for a specific flame spread rating. Untreated [2] MDF has been tested for flame spread by a number of different manufacturers and the results met the Class III or C rating. The Department of Housing and Urban Development(HUD) in their Manufactured Home Construction and Safety Standards(Section 3280.203) accepts MDF 3/8 inch and thicker as having a flame spread rating of 76 to 200 for general use. The American Wood Council (AWC) of the American Forest and Paper Association (AF&PA) has published information in their “Design for Code Acceptance” series (DCA1) relating to Flame Spread Performance of Wood Products. The document can be found at www.awc.org. Table 1 in that document places MDF in the Class III or C rating. Likewise, Table 2 in that document places factory finished products (i.e. printed or with overlays) containing untreated particleboard and MDF substrates in the Class III or C flame spread rating. Smoke data specific to every product is currently not available; however other manufacturers have found typical values of 100-200 for smoke developed. The AF&PA document states that “a smoke-developed index was measured for some of the wood products listed in Tables 1 and 2”. None of the products tested exceeded 450, a limiting value commonly used in building code regulations. Interlam's MDF treated with fire-retardant [3] (FR) additives are certified by Underwriters Laboratories to have a Class A or Class I flame spread rating and must be specifically ordered as an available option with an up charge. [2] Without a fire-retardant additive [3] Trade names: Premier® FR, VESTA FR MDF Color Consistency of IDF, MDF, SDF, FR & Valchromat Products: Our Carved MDF wall panel products are manufactured from recycled/recovered forest products; therefore due to the color of the raw material, the raw unfinished Art Diffusion products will have variations in color and fibre. This condition is relevant when the designer wishes to clear coat the raw product. The end result will be a natural variation of color and fibre found naturally within the fibre used for the manufacturing of the board products. Interlam will not guarantee a color match of raw boards. Interlam currently utilizes three mills for the fabrication of raw products, each of which contain distinct variations. This variation is especially noticeable when a class A fire rated board is used. The mills have begun to die the center core a pale orange color to distinguish it from other board products. Due to previously stated variables, we do not offer stain as a stock finish. Pattern Number: Every pattern has an identifying number such as “SOT-001”, “W1208” or “POP001”. The pattern choice is the second step after choosing a material for the core. A full page is dedicated to each pattern online at Updated: 01/02/2012

Open the catalog to page 1

www.interlam-design.com complete with pattern characteristics and photos of the actual product. Do not place an order without requesting a sample and verifying the scale of the pattern. A hand has been included in the pattern shots for use as scale; however this alone cannot give a true representation of the pattern appearance. Panel Size: The standard panel size is 48” x 96” (4’ x 8’). Custom panels can be produced up to 60” wide and up to 120” long. Not all core materials are available in the larger sizes. Please contact Interlam to determine material availability for custom projects. For...

Open the catalog to page 2

When ordering continuous flow panels, the customer must provide a layout indicating the dimensions of the project area as well as the dimensions of all of the individual panels. Most patterns are available as continuous flow. Contact Interlam, Corp. for specific applications. Repeating Pattern Type - Repeating patterns allow the customer to fill a project area of any size using identical standard 4’ X 8’ panels. The standard panels fit together top-to-bottom and left-side to right- side creating a monolithic appearance. In the illustration below, 5 identical repeating panels are shown to...

Open the catalog to page 3

Fixed Set Pattern Type - Fixed sets are two or more non-repeating 4’ X 8’ panels that fit together only one way. Single panels may be selected out of a set, or the entire set may be used in a project. Fixed set panels may also be mirrored. A-B Repeat Type - This type of pattern repeats every other panel. Because of this an “A” and a “B” version of the pattern is manufactured and labeled accordingly. The two versions of the panel are then alternated in the final installation in order to achieve a monolithic appearance. Minimum Recommended Thickness - The minimum thickness given for each...

Open the catalog to page 4All INTERLAM catalogs and technical brochures

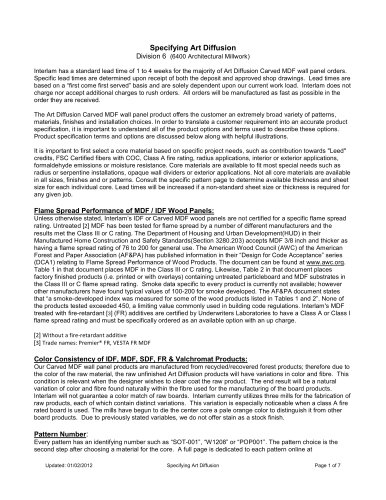

-

METAL SCREENS

2 Pages

-

MOTION I

12 Pages

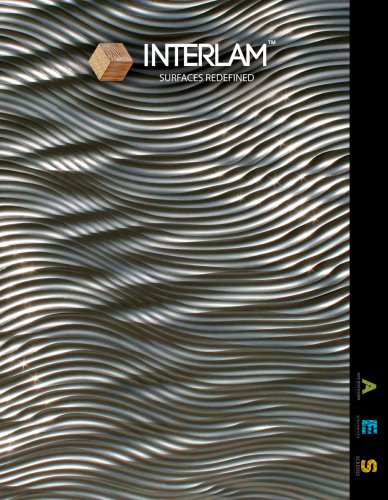

-

INTERLAM

74 Pages

-

MOTION II

4 Pages

-

Specifying Screens

3 Pages

-

Specifying Elements

6 Pages

-

Specifying Art Diffusion

4 Pages

-

INTERLAM BOOKLET

28 Pages