Catalog excerpts

How to Specify INTERLAM Laminated Glass Systems An Interlam Design code is an identification number for a particular paper color. One to two sheets of papers are typically used for the construction of the laminated glass. Since the panel can be ordered as single sided or double sided, the ID number of the papers should be designated. The thickness of the overall glass panel will vary based on the thickness of the individual components. The following options apply: 3/16” clear glass + 1 layer EVA+ paper design+ 1 layer EVA+ 3/16” clear glass= Single sided panel .484” 3/16” clear glass + 1 layer EVA+ paper design+ 1 layer EVA+ paper design+ 1 layer EVA + 3/16” clear glass= Double sided panel .539” 1/4” clear glass + 1 layer EVA+ paper design+ 1 layer EVA+ 1/4” clear glass= Single sided panel .609” 1/4” clear glass + 1 layer EVA+ paper design+ 1 layer EVA+ paper design+ 1 layer EVA + 1/4” clear glass= Double sided panel .664” 3/16” ULTRA clear glass + 1 layer EVA+ paper design+ 1 layer EVA+ 3/16” ULTRA clear glass= Single sided panel .484” 3/16” ULTRA clear glass + 1 layer EVA+ paper design+ 1 layer EVA+ paper design+ 1 layer EVA + 3/16” ULTRA clear glass= Double sided panel .539” 1/4” ULTRA clear glass + 1 layer EVA+ paper design+ 1 layer EVA+ 1/4” ULTRA clear glass= Single sided panel .609” 1/4” ULTRA clear glass + 1 layer EVA+ paper design+ 1 layer EVA+ paper design+ 1 layer EVA + 1/4” ULTRA clear glass= Double sided panel .664” Interlam’s Laminated Glass Systems quality complies with ASTM C 1172 safety standards for laminated glass. Produced with a formulated interlayer and substrate designed to laminate under heat and pressure between two pieces of (thickness, type and color) glass. ***** Safety glass can be fabricated by bonding two or more glass panes with a transparent, flexible interlayment material. Laminated glass does qualify as safety glass in compliance with ANSI Z97.1 and CFR 16CFR 1201. When broken, laminated glass tends to remain in place with glass particles adhered to interlayment. Interlam uses EVA high adhesive film, which is made of polymer resins of Ethylene Vinyl Acetate. This product ensures high tensile strength, outstanding cohesion and superior tolerance to higher temperatures.

Open the catalog to page 1

Short Form Specifications: CSI SECTION 8810 INTERIOR LAMINATED GLASS Provide LAMINATED GLASS SYSTEMS per the following: Choose one from each layer 1st outer layer FRONT: 3/16” clear, 3/16” ultra clear, ¼” Clear, ¼” ultra clear 1st inner layer: Provide the pattern and color number from selection offered 2nd inner layer: Same as above if the panels are to be double sided. 2ndouter layer BACK: 3/16” clear, 3/16” ultra clear, ¼” Clear, ¼” ultra clear Laminated Glass Systems panels to be manufactured by: Interlam, Corp. 391 Hickory Street Mount AIry, NC 27030 336-786-6254 p 336-786-9460 f...

Open the catalog to page 2All INTERLAM catalogs and technical brochures

-

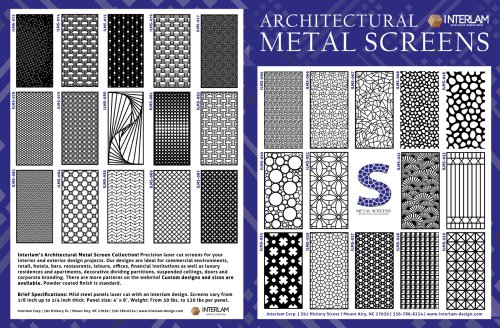

METAL SCREENS

2 Pages

-

MOTION I

12 Pages

-

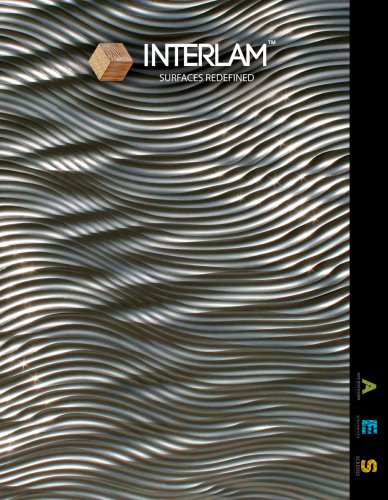

INTERLAM

74 Pages

-

MOTION II

4 Pages

-

Specifying Screens

3 Pages

-

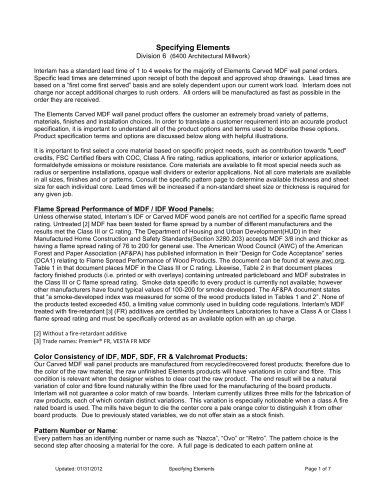

Specifying Elements

6 Pages

-

Specifying Art Diffusion

7 Pages

-

Specifying Art Diffusion

4 Pages

-

INTERLAM BOOKLET

28 Pages