Website:

INTERAL CUHADAROGLU METAL SANAYI

Website:

INTERAL CUHADAROGLU METAL SANAYI

Catalog excerpts

efectis trance SASU au capital de 1 512 170 € RCS Versailles B 490 550 712 - Code NAF 743 B Concerning : A double leaves door. Frame : Aluminium profiles, reference CUHADAROGLU Fireboard : Plasterboard with aluminium panel facing each side Reference FIREBOARD (KNAUF) Fire direction: Fire opposite to hinges Clear way dimensions : 2036x 2118 mm (w x h) Overall dimensions : 2200 x 2200 mm (w x h) Applicant : CUHADAROGLU METAL Yakuplu Koyu Yolu TURKEY - 34900 BEYLIKDUZU / ISTANBUL This test report includes 37 sheets. Copies of this document are allowed only in its enterity. The approval of the Test department of the COFRAC certifies the competence of the test laboratories only for the tests covered by the approval. Siege Damaine de Saint-Paul 102. route de Llmours france@efectis.conn F 78471 Samt-Remy-ies-Chevreuse Cedex www.efectis.com

Open the catalog to page 1

Test report n° 09 - H- 261 Page 2 / 37 Fire resistance test of a fire boarded door unit with two leaves, in conformity with the general requirements of standard NF EN 1363-1, the additional or substitute procedures of standard NF EN 1363-2, and the particular requirements of standard NF EN 1634-1 "Fire resistance tests of door-units and closing units - Part 1 : Fire-resistant doors and closing devices". Name : EFECTIS France Adresse : Voie Romaine Test date : June 5th 2009 Profile Manufacturer Address : CUHADAROGLU FP 67 : CUHADAROGLU : Yakuplu Koyu Yolu TURKEY - 34900...

Open the catalog to page 2

5. DESCRIPTION OF TEST SPECIMEN The test specimen (dimensions, fire direction, supporting frame and assembling) was supplied by the Applicant to the Test Laboratory on his own initiative, in conformity with clause 12 of standard NF EN 1363-1. The test specimen was a fire boarded double leaf door-unit with an insulated aluminium framework. : Dimensions Clear way Main leaf Semi fixed leaf Thickness 5.2 PART LIST Established in accordance with the indications provided by the party requesting the test: see plates 1 to 8 5.3 DETAILED DESCRIPTION OF THE SPECIMEN Note: The drawings shown on plates...

Open the catalog to page 3

Test report n° 09 - H- 261 Page 4 / 37 5.3.1.2 Leaves The door-unit consisted of double leaf door, each of them with two fireboards separated by a 68.8 x 70 mm aluminium profile, which cover a clear way of 2030x 2114 mm (w x h). The leaves were fitted out with to security bolts each and they were fixed to the doorframe by three hinges per leaf specified in coming chapter. The leaves were kept close by a door lock associated with a fireproof handle and a door-closer on top on hinge side for each leaf; and a push bar on exposed side for the main leaf. The leaves were made of aluminium...

Open the catalog to page 4

Test report n° 09 - H- 261 Page 5 / 37 The specifications supplied by the Applicant were detailed enough to enable the Test Laboratory to carry out a detailed examination of the test specimen before the test and to check the accuracy of the information supplied. The choice and the definition of this test specimen were carried out by the Applicant according to paragraph 12 of standard NF-EN 1363-1. The assembly of the element was realised by the Applicant. The sealing consists of a silicone strip reference Rubson haute temperature, all around the frame, on the exposed and unexposed side....

Open the catalog to page 5

Test report n° 09 - H- 261 Page 6 / 37 7.3 SUITABILITY (§ 5.1.1.1) The door-leaves of the door-unit were submitted to 25 opening/closing operations by hand at normal operating speed. No visible disorder was noted after this test. 7.3.1 Automatic closing test The test carried out was satisfactory. In conformity with the procedures prescribed in section 10.1.2 of standard NF EN 1634-1, the following clearances were measured: Theoretical Actual > Main leaf • Upper rail • Hinges side • Vertically on lock side • At threshold > Semi fixed leaf Theoretical Actual • Upper rail • Hinges...

Open the catalog to page 6

Test report n° 09 - H- 261 Page 7 / 37 The fire test was carried out with the hinges opposite to fire. The fire test was carried out with the door closers opposite to fire. The locations of the sensors are shown on plate nr 9. The readings are recorded on the plates mentioned hereafter. 8.1.1 Temperature in laboratory The ambient temperature was measured, during the test, by thermocouple n° 7. See plate n° 10. 8.1.2 Temperature in the furnace They were measured in conformity with standard NF EN 1363-1 by 6 plate pyrometers with their metal face towards the back of the furnace: See plate...

Open the catalog to page 7

In conformity with the requirements of standard NF EN 1363-1, the pressure inside the furnace was continuously controlled throughout the whole test. Taking into account the dimensions of the door-unit and the location of the pressure sensor, the prescribed value was established at 16 Pa. See plate nr19 In conformity with the requirements of standards NF EN 1634-1 and NF EN 1363-2, the radiation from the unexposed side of the door-unit was measured and recorded by means of a radiometer: See plate nr 20 Copies of this document are allowed only in its enterity

Open the catalog to page 8

Test report n° 09 - H- 261 Page 9 / 37 In conformity with the standards mentioned in section 1, the times during which the specimen meets the fire resistance criteria may be regarded as follows: 10.1.1 FIRE INTEGRITY of the door unit with door closer 10.1.1.1 Cotton-wool pad Duration : NINETY FIVE MINUTES - (95 min) Cause of limitation : No failure until the and of the test 10.1.1.2 Gap gauge Duration : NINETY FIVE MINUTES - (95 min) Cause of limitation : No failure until the and of the test 10.1.1.3 Sustained lighting Duration : SIXTY EIGHT MINUTES - (68 min) Cause of...

Open the catalog to page 9

Test report n° 09 - H- 261 Page 10 / 37 10.2.1 FIRE INTEGRITY of the door unit with door closer 10.2.1.1 Cotton-wool pad Duration : NINETY FIVE MINUTES - (95 min) Cause of limitation : No failure until the end of the test 10.2.1.2 Gap gauge Duration : NINETY FIVE MINUTES - (95 min) Cause of limitation : No failure until the end of the test 10.2.1.3 Sustained lighting Duration : NINETY FOUR MINUTES - (94 min) Cause of limitation : Sustained flaming for a duration of more than 10 seconds between the leaf and the frame, in the top left corner of the leaf 10.2.2 THERMAL...

Open the catalog to page 10All INTERAL CUHADAROGLU METAL SANAYI catalogs and technical brochures

-

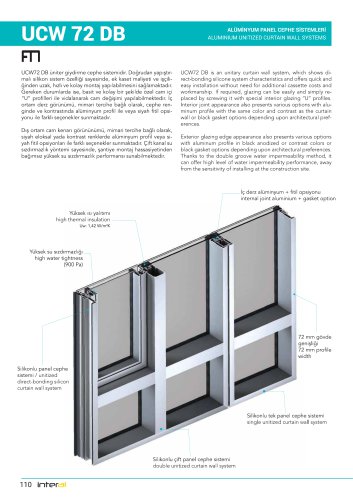

UCW 72 DB

2 Pages

-

IZO KE 50

2 Pages

-

UCW 72 CS

2 Pages

-

SKY 50 - 60 - 70

2 Pages

-

DS 50 VF

2 Pages

-

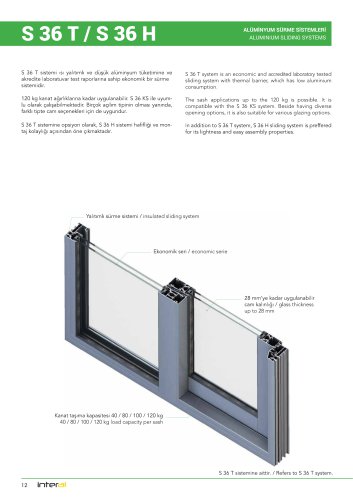

S 36 T / S 36 H

2 Pages

-

Security systems

6 Pages

-

Interwall

34 Pages

-

Product catalogue

31 Pages

-

C-Alu Catalogue

20 Pages