Catalog excerpts

FOODSERVICE DISPOSER Installation Manual The Danger signal indicates an immediately hazardous situation which, if not avoided, will result in death or serious injury. The Warning signal alerts you to potential hazards or unsafe practices which, if not avoided, could result in severe personal injury or death. The Caution signal alerts you to hazards of unsafe practices which, if not avoided, may result in minor personal injury or property damage. Please be certain that the person who installs or uses this appliance carefully reads and understands the Safety Instructions contained in this manual. www.insinkerator.com/foodservice Part No. 13954 Rev.A

Open the catalog to page 1

The InSinkErator Foodservice food waste disposer is UL® and CSA® Listed when installed in conjunction with InSinkErator mounting adaptors and controls (see Figure See Table 1 (page 4) for the approved disposer/ mounting adaptor combinations. See Table 3 (page 9) for the approved disposer/control combinations. Important - These installation instructions are for the benefit of the installing contractor. InSinkErator and/or InSinkErator Factory Authorized Service Centers do not make original installations. For technical information not covered in these instructions, contact the supplier, an...

Open the catalog to page 3

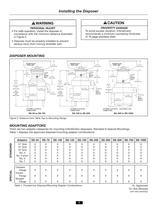

Installing the Disposer PROPERTY DAMAGE To avoid excess vibration, InSinkErator recommends a minimum countertop thickness of 16 gage stainless steel. PERSONAL INJURY • For safe operation, install the disposer in compliance with the minimum distance illustrated in Figure 2. • Disposer must be properly installed to prevent serious injury from moving shredder part. DISPOSER MOUNTING 6-1/2" (165.10 mm) 6-5/8" (168.28 mm) 6-1/2" (165.10 mm) 6-5/8" (168.28 mm) 2-3/4" (69.85 mm) 3-3/8" (85.73 mm) 24-1/4" TO 32-1/2" (615.95 mm TO 825.50 mm) 17" (431.80 mm) (WITH OPTIONAL LEGS INSTALLED) 13" (330.20...

Open the catalog to page 4

Standard InSinkErator Mountings #5 MOUNTING ASSEMBLY Follow these instructions to install a #5 sink flange to a standard 3-1/2 to 4 inch sink opening. (1) Stopper 1. Unscrew the three backup screws (6) until they are flush with the upper mounting flange (5) surface. Pry the retainer ring (7) free from the strainer flange (2) with a screwdriver and separate all mounting assembly parts (2-7). (2) Strainer Flange 2. Form a 3/4" thick ring of top grade oil base putty around the sink opening (use a non-hardening putty). Insert the strainer flange (2) into the sink opening and press firmly in...

Open the catalog to page 5

Standard InSinkErator Mountings #6, #7, & SINK BOWL MOUNTING ASSEMBLIES 1. Place the mounting flange (1) over the existing collar 4. adaptor connection lip or sink bowl flange (this may require some force). 2. Push the mounting flange up out of the way and fit the groove in the mounting gasket (2) onto the connection lip. Make sure the gasket is fully seated 3. Push the mounting flange down over the mounting gasket, fitting the threaded mounting flange fasteners into the recesses in the top of the mounting gasket. Disposer Body Flange -► From the bottom, insert two screws through opposite...

Open the catalog to page 6

Plumbing Connections Install the flow control valve, water solenoid valve, and the syphon breaker according to the direction of the flow arrows marked on each valve body (see Figure 9). PROPERTY DAMAGE These plumbing instructions were written for an experienced competent installer. If the installer is not experienced in plumbing installation, InSinkErator recommends that competent professional assistance is sought. Damage to the disposer or accessories as a result of improper installation is not covered under warranty. All installations must comply with local plumbing codes. NOTE: A syphon...

Open the catalog to page 7

Standard Motor Connection Wiring Diagrams NOTE: The diagrams below show standard motor connection wiring for a manual switch operation. For alternate controls, please refer to the control panel installation manual. 4 5 6 2 MOTOR LEAD WIRE# 1 2 5 11 1 7 L1 6 L2 L1 Figure 11. Incoming 208-230V Single Phase Line Power 12 4 MOTOR LEAD WIRE# 1 L1 7 2 L2 8 3 6 MOTOR LEAD WIRE# Figure 10. Incoming 115V Single Phase Line Power 10 5 4 7 3 L2 4 3 7 5 8 6 9 MOTOR LEAD WIRE# 9 1 Figure 12. Incoming 208-230V Three Phase Line Power 3 L1 L3 2 L2 10 11 12 L3 Figure 13. Incoming 460V Three Phase Line Power 8

Open the catalog to page 8

Electrical Connections ELECTRICAL CONNECTIONS To connect the disposer to the electricity: ELECTRICAL SHOCK • Turn off the electrical supply to the disposer before servicing. Test the circuit with a voltmeter or circuit tester to ensure the power is off. 1. Remove the screw in the center of the disposer terminal box. • Installation must conform to all local electrical codes. 3. Connect an electrical conduit connector to the hole in the bottom of the exposed wiring compartment. 2. Pull the terminal box out of the stainless steel trim shell. • All control centers and disposers must be...

Open the catalog to page 9

Operating Instructions OPERATING THE DISPOSER 1. Make sure there are no foreign objects in the disposer grind chamber. Do not pre-load the disposer with food waste prior to starting. FIRE HAZARD To minimize the possibility of fire, do not store flammable items near the disposer. Do not use or store gasoline or other flammable liquids near the disposer. 2. Push the start button on the control switch. The disposer will run and water will flow into the disposer. 3. Feed food waste into the disposer in a steady, continuous flow. 4. When all food waste is flushed away, push the stop button on...

Open the catalog to page 10

Troubleshooting ELECTRICAL SHOCK Disconnect power before servicing. Troubleshooting for problems other than what is listed below should be performed by a qualified service person. Troubleshooting performed by untrained personnel could result in electrical shock or damage to the disposer. Disconnect power before servicing. PROBLEM Disposer will not start and water does not flow. POSSIBLE CAUSE SOLUTION • Turn on electrical supply. • Electrical disconnect switch has been reactivated and 30-second delay has not yet expired. • Wait 30 seconds and try starting again. • Disposer overload...

Open the catalog to page 11All InSinkErator catalogs and technical brochures

-

SS SERIES

4 Pages

-

HWT-F1000S

1 Pages

-

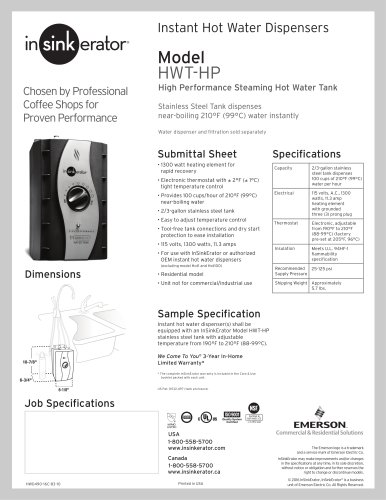

HWT-HP

1 Pages

-

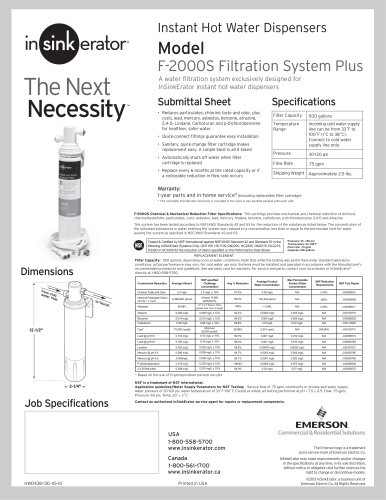

F-2000

1 Pages

-

F-601R

1 Pages

-

F-201R Replacement Filter

1 Pages

-

F-1000 Replacement Filter

1 Pages

-

WASTEXPRESS®

4 Pages

-

HOT WATER DISPENSERS

2 Pages

-

FOOD WASTE DISPOSERS

5 Pages

-

Evolution Compact®

1 Pages

-

Evolution Excel®

1 Pages

-

SinkTop Switch?

2 Pages

-

SST-FLTR

1 Pages

-

H770SS

1 Pages

-

H990-SS

1 Pages

-

H-Wave-SS

1 Pages

-

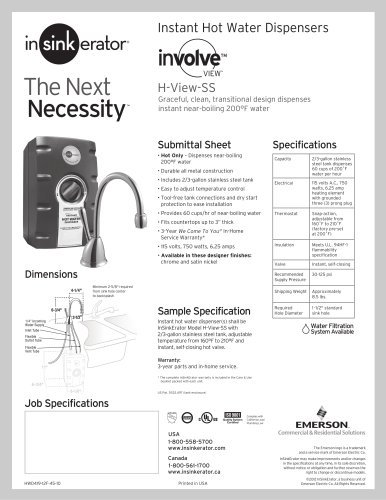

H-View-SS

1 Pages

-

HC-Wave-SS

1 Pages

-

HC-View-SS

1 Pages

-

F-GN1100

1 Pages

-

F-HC1100

1 Pages

-

F-GN2215

1 Pages

-

F-HC2215

1 Pages

-

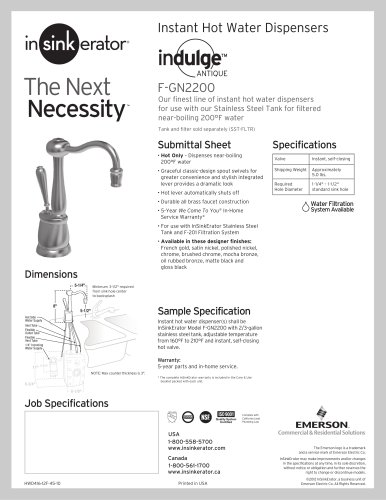

F-GN2200

1 Pages

-

F-HC2200

1 Pages

-

F-HC3300

1 Pages

-

F-H3300

1 Pages

-

SinkTop Switch

2 Pages

-

Water Dispensing

20 Pages

-

Badger 1

1 Pages

-

Badger 5

1 Pages

-

Badger 5XP

1 Pages

-

Pulper Systems Model WX-300

4 Pages

-

Evolution Septic Assist

1 Pages

-

Evolution Cover Control

1 Pages

-

Evolution Essential

1 Pages

Archived catalogs

-

Finish Matching Guide

2 Pages

-

Evolution Compact

1 Pages

-

Evolution Excel

1 Pages

-

Aqua Saver Brochure

2 Pages

-

Hot & Cold Water Now

7 Pages