Catalog excerpts

DATA SHEET Product description BITEXTENE/MT waterproofing membranes are produced by co-extruding a specially formulated elastomeric compound consisting of a complex dispersion of rubbers and copolymers in selected distilled bitumens with a non-woven continuous filament stabilized polyester fiber reinforcing mat located midway through the membrane's thickness and acting in total synergy with it. The BITEXTENE/MT Series consists of two versions: BITEXTENE FLEX/MT3 and MT4, with thicknesses of 3 and 4 mm respectively. Both faces are coated with TEXTENE® preformed textured polymer fiber film. BITEXTENE FLEX/MT Series membranes are supplied in strapped rolls, each accompanied by a Quality Control Certificate. They comply with CE marking requirements where applicable, and contain no asbestos, tar or other dangerous substances. Recommended uses BITEXTENE FLEX/MT Series membranes are ideal for all applications calling for excellent bonding to the substrate, as is needed when waterproofing below-grade walls, vehicular traffic-bearing surfaces, etc. Compared to ordinary finishes, the TEXTENE® treatment is cleaner to work with and releases less dust, ensuring low environmental impact at the installation site. The two textured faces improve membrane torch application, making for faster installation and more effective adhesion to the substrate. Membrane suitability for applications where CE marking is required is detailed in the table below(1). For detailed documentation and guidance regarding product application, consult IMPER ITALIA srl Technical Services. (1) In compliance with applicable standards and AISPEC-MBP guidelines. (2) Overcoated with Elastomul series, Parwenol 4822 AL or ALLABIT 822 AL protective paints. Methods of application BITEXTENE FLEX/MT Series membranes are designed for easy torch application after priming, or are secured using mechanical means. They are also suitable for cold application using ADITHENE adhesive. Waterproofing performance will depend to a significant extent on application methods. Designed for versatility and ease of application, BITEXTENE FLEX/MT membranes are laid using standard tools: a propane torch, trowel and cutter. Special care must be taken at joins, which must be overlapped. Membrane must be laid to allow side laps of 8 to 10 cm and end laps of 12 to 15 cm. For detailed documentation and guidance in selecting the most appropriate procedures for any job, consult IMPER ITALIA srl Technical Services, who will be happy to provide assistance and advice in designing special waterproofing systems and helping you make the best use of these materials.

Open the catalog to page 1

(BITEXTENE FLEX/MT SERIES continued) Notes: (1) In compliance with applicable standards and AISPEC-MBP guidelines. (3) Or failure away from joints (2) Not determined, because not relevant for application. (4) Euroclass. As IMPER ITALIA srl has no control over how or where its products are supplied (e.g., over substrates, service conditions, or compliance with instructions), the company cannot accept any liability arising from the use of its product or the results obtained. IMPER ITALIA srl pursues a policy of continuous product improvement. As a result, the company reserves the right...

Open the catalog to page 2All Imper Italia catalogs and technical brochures

-

STAR

2 Pages

-

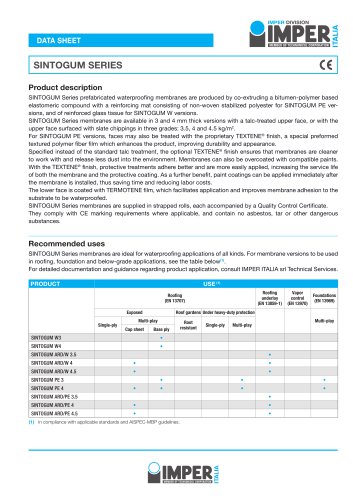

SINTOGUM SERIES

2 Pages

-

PARALON 77 PLUS

2 Pages

-

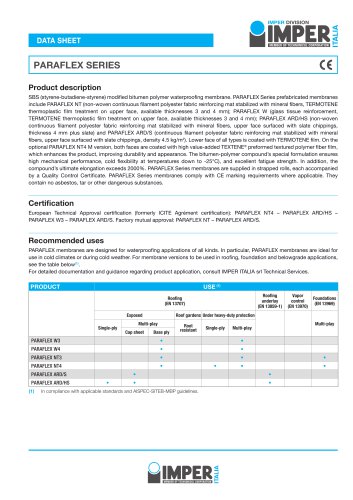

PARAFLEX SERIES

2 Pages

-

CATALOGUE 2014

56 Pages

-

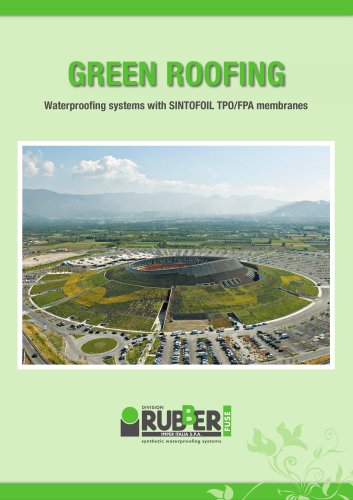

Green Roof

8 Pages

-

Cool Roof

4 Pages

-

Photovoltaic

2 Pages