Catalog excerpts

^■V INNOVATIVE HOME TECHNOLOGY

Open the catalog to page 1

COMPOSITE DECKING Hollow Board 4200x140x24 Hollow Board 2300x140x24 CI-Grey BR-Rose Beige BF-Beech Beige RW-Red Wood CH-Chocolate NE-Dark Black Length tolerance Weight mL - 2,36 ± 0,2kg Brushed Non-slip Reference item example - Hollow Board 4200x140x24 in Beech Beige: DEC01420BF Solid Board 4200x140x24 Solid Board 2300x140x24 CI-Grey BR-Rose Beige BF-Beech Beige RW-Red Wood CH-Chocolate NE-Dark Black Weight mL - 4,17 ± 0,2kg Brushed Non-slip Length tolerance Reference item example - Hollow Board 4200x140x24 in Beech Beige: DEC03420BF Length tolerance Weight mL - 0,69 ± 0,1kg 45,0+1,0 -1,0...

Open the catalog to page 2

Length tolerance CI-Grey BR-Rose Beige BF-Beech Beige RW-Red Wood CH-Chocolate NE-Dark Black CI-Grey BR-Rose Beige BF-Beech Beige RW-Red Wood CH-Chocolate NE-Dark Black 46,0+1,0 -1,0 Reference item example - Fastener 2300x46x8 in Dark Black: DEU21230NE Length tolerance Reference item example - Step 2300x101x56 in Dark Black: DEU22230NE Quick-fix Intermediate Clip PR-Black CZ-Grey CA-Brown Quick-fix Pro Intermediate Clip PR-Black CZ-Grey CA-Brown Reference item example - Quick-fix Intermediate Clip in Black: DEC70001PR Reference item exemple - Quick-fix Pro Intermediate Clip in Black:...

Open the catalog to page 3

Quick-fix Terminal Clip Fastener Holder CI-Grey BF-Beech Beige RW-Red Wood CH-Chocolate NE- Dark Black Inox Screw 6x60 Whith Plug Ø8 Reference item exemple - Quick-fix Terminal Clip in Black: DEC70002PR Reference item exemple - Fastener Holder in Black: DEC70003PR Reference item exemple - Board End Cap 140x24 in Grey: DEC70005CI Reference item example - Inox Screw 6x60 Whith Plug Ø8: DEC80001IX Note: Screw PZ3 with Stainless Steel A2

Open the catalog to page 4

UND/PALLET COLOUR Self Drilling Screw Reference item exemple - Self Drilling Screw 3,5x25 Note: Screw PH2 with Stainless Steel A2 Self Drilling Screw Reference item exemple - Self Drilling Screw 4,2x60 Note: Screw PH2 with Stainless Steel A2 CTOOLToolto Install Reference item exemple - CTOOL Tool to Install Note: Includes 1/4 Bit with 4mm Slit Reference item exemple - 1 /4 Bit with 4mm for CTOOL

Open the catalog to page 5

ESTIMATED AMOUNT BY SQ.M FOR RESIDENTIAL USE BOARD 2300x140x24 QUICK-FIX JOIST 2300x45x27 QUICK-FIX INTERMEDIATE CLIP QUICK-FIX TERMINAL CLIP (The amounts given are merely examples, given that actual need will depend on the typology of the area and the way the decking is applied.) ≈ 3 Und/sq.m ≈ 1,31 Und/sq.m ≈ 20 Und/sq.m ≈ 2 Und/sq.m

Open the catalog to page 6

COMPOSITE DECKING ESTIMATED AMOUNT BY SQ.M FOR COMMERCIAL USE BOARD 2300x140x24 QUICK-FIX JOIST 2300x45x27 QUICK-FIX INTERMEDIATE CLIP QUICK-FIX TERMINAL CLIP ≈ 3 Und/sq.m ≈ 1,52 Und/sq.m ≈ 23 Und/sq.m ≈ 3 Und/sq.m (The amounts given are merely examples, given that actual need will depend on the typology of the area and the way the decking is applied.)

Open the catalog to page 7

GENERAL RULES • Items from the CDECK range should be stored on a flat surface, and the items should be protected from direct exposure to sunlight, rain, snow, and other adverse climatic conditions. • The WPC profiles (e.g.: Boards) should remain on site for at least 48 hours before being fitted, so that the material can adapt to the climatic conditions. • The CDECK profiles are not structural profiles, and should not be installed as suspended constructions. •The CDECK range is a floating deck range, so its boards should never be screwed to the base or fastened to any items other than those...

Open the catalog to page 8

COMPOSITE DECKING The installation surface should be completely flat and stable (e.g. 10 - 15 cm of solid concrete), and should slope for water drainage by at least 5 mm per metre in the direction of the Joists and in the direction of the Boards.

Open the catalog to page 9

2.1 LAGGED ASSEMBLY (ENGLISH ASSEMBLY) 2.2 LAGGED ASSEMBLY (ENGLISH ASSEMBLY) AT 45º

Open the catalog to page 10

COMPOSITE DECKING Board 2300 - 6,5mm Board 4200 - 12mm Residential use MAX. 400mm Commercial use MAX. 350mm

Open the catalog to page 11

FLASH HEAD SCREW CONICAL HEAD SCREW ø6x60

Open the catalog to page 12

COMPOSITE DECKING Irrespective of the distance between the Joists, under no circumstances can the Boards be supported by less than 3 Joists. For assembly involving boards arranged top to top, 2 Joists should always be used (1 for each board) with the respective Clips.

Open the catalog to page 13

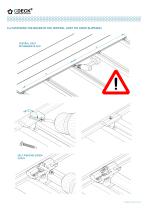

COMPOSITE DECKING 3.6 FASTENING THE BOARD IN THE CENTRAL JOIST (TO AVOID SLIPPAGE) CENTRAL JOIST INTERMEDIATE CLIP SELF PIERCING SCREW 3,5X25

Open the catalog to page 15

COMPOSITE DECKING 4. CDECK STEP ASSEMBLY Conical head screw 6x60 Self piercing screw 4,2x60

Open the catalog to page 17

5. FASTENING THE CDECK FASTENER 5.1

Open the catalog to page 18

COMPOSITE DECKING

Open the catalog to page 19

6.2 PLACING THE BOARD END CAP OF THE BOARD 6.1 OPENING OF HOLES IN THE LOWER PART FOR DRAINAGE/VENTILATION

Open the catalog to page 20

COMPOSITE DECKING 7. USING THE CTOOL TOOL 7.1 CLEARENCE OF THE BOARDS 2300 7.3 CLEARENCE FROM THE FIXED ELEMENTS

Open the catalog to page 21

7.5 POSITIONING OF THE BOARD'S CENTRAL CLAMPING SCREW 7.6 OPENING AND CLOSING KEY FOR THE QUICK-FIX PRO INTERMEDIATE CLIP

Open the catalog to page 22

COMPOSITE DECKING 8. UNINSTALLING AND REINSTALLING BOARDS WITH THE QUICK-FIX PRO INTERMEDIATE CLIP 8.1 INDIVIDUAL OPENING OF THE BOARD 8.2 REINSTALLING THE OPEN BOARD

Open the catalog to page 23

EVITAR ESCORREGAMENTO) 9. CDECK MAINTENANCE 9.1 INITIAL MAINTENANCE During fitting it is common for a lot of dust to be produced, so we recommend the deck to be thoroughly cleaned with water, mild detergent and a soft brush. You can use a garden hose or a high pressure apparatus (at a minimum distance of 30 cm and a maximum pressure of 150 bar), always washing the boards in the direction of the grooves. 9.2 REGULAR MAINTENANCE The composite CDECK is easy to maintain. However, it still needs regular cleaning. As with any covering made of wood, synthetic materials, stone, etc., the CDECK may...

Open the catalog to page 24All IHT LDA catalogs and technical brochures

-

Catalog

40 Pages