Catalog excerpts

Installation, Start-Up and Maintenance Manual EF and EMF Flaked Ice Machines Series 250 through 2306 Ice-O-Matic 11100 East 45th Ave Denver, Colorado 80239 Part Number 9081178-01 Print Date 10/08

Open the catalog to page 1

EF and EMF Series Introduction How To Use This Manual Ice-O-Matic provides this manual as an aid to the service technician in installation and maintenance of the EF and EMF Series flake ice machines. Do not attempt to perform installation, start-up or maintenance unless you have read and fully understand this manual. If at any time you encounter conditions that are not addressed in this manual, call, E-mail or write the Ice-O-Matic Service Department: Ice-O-Matic 11100 E. 45th Ave. Denver, Co. 80239 Attn: Technical Service Department E-Mail: Tech.service@iceomatic.com Telephone Numbers...

Open the catalog to page 2

EF and EMF Series Table of Contents Introduction Page i Table of Contents Page ii Freight Claim Procedure Page iii Warranty Page iv Model Number and Serial Number Format Page 1 Installation Guidelines Page 2-3 Remote Condenser Guidelines Page 4 Electrical and Plumbing Requirements Page 5-7 How the Machine Works Page 8 Start-Up Procedure Page 9-10 General Maintenance Page11 Cleaning Procedure Page 12 Cabinet Care Page 13 Winterizing Procedure Page 14 Maintenance Record Page 15 Page ii

Open the catalog to page 3

EF and EMF Series Freight Claim Procedure Important! Inspect Promptly This merchandise has been carefully inspected and packed in accordance with the carrier’s packing specifications. Responsibility for safe delivery has been assumed by the carrier. If loss or damage occurs, you as the consignee must file a claim with the carrier and hold container for carrier’s inspection. Visible Loss or Damage Any external evidence of loss or damage must be fully described and noted on your freight bill or express receipt and signed by the carrier’s agent. Claim should be filed on a form available from...

Open the catalog to page 4

EF and EMF Series Warranty Ice-O-Matic Parts and Labor Domestic & International Limited Warranty Mile High Equipment LLC (the “Company”) warrants Ice-O-Matic brand ice machines, ice dispensers, remote condensers, water filters, and ice storage bins to the end customer against defects in material and factory workmanship for the following: • Cube ice machines,”GEM” model compressed ice machines ,” MFI” model flake ice machines and remote condensers. - Thirty-six (36) months parts and labor • “EF” and “EMF” model flake ice machines - Twenty-four (24) months parts and labor • CD model...

Open the catalog to page 5

EF and EMF Series Model and Serial Number Format Model and Serial Number Format (Sample of Serial Number) The serial number format and machine specifics are detailed on the data plate. EMF 45 0 A S 2 Design Level Stainless Steel Cabinet Condenser Type: A=Air, W=Water, R=Remote Voltage: 0=115V, 6=230V/60Hz. 5=240V/50Hz. Approximate Production X 10 in 24 hours @70°FA/50°FW Series: Environmental Modular Flaker (Uses HFC Refrigerant) This format is 14 characters long and begins with a date code followed by the Ice-O-Matic identifier, and then a sequential number. This is an entirely numerical...

Open the catalog to page 6

EF and EMF Series Installation Guidelines Installation Guidelines For proper operation of the Ice-O-Matic ice machine, the following installation guidelines must be followed. Failure to do so may result in loss of production capacity, premature part failures, and may void all warranties. Reference the installation parameters prior to installing the machine: Ambient Operating Temperatures Minimum Operating Temperature: 50°F (10°C) Maximum Operating Temperature 100°F (38°C), 110°F (43°C) on 50 Hz. Models. Note: Ice-O-Matic icemakers and dispensers are not approved for outdoor installation....

Open the catalog to page 7

EF and EMF Series Installation Guidelines Set-Up ●Carefully uncrate machine and check for visible damage. If any damage is noted, stop installation and follow instructions on Page iii. Install Junction Box ●Remove skid bolts or screws and lift machine off of the skid. ●Install legs (packaged inside bin) on base of machine or storage bin. ●Remove and discard the 2 bolts at the rear of the EF series cabinet that secure the chassis for shipping. ●Place the EMF series model on top of the bin or bin top, install the downchute seal and attach the ice machine with the hardware provided. Insure...

Open the catalog to page 8

EF and EMF Series Remote Condenser Guidelines Remote Condenser Installation The EMF1106R2 and EMF2306R2 remote ice makers incorporate the mixing valve in the condenser. This configuration allows up to a 100 foot calculated remote line set run. Reference the diagram below to calculate the maximum 100 foot line set run. For proper operation of the Ice-O-Matic ice machine, the following installation guidelines must be followed. Failure to do so may result in loss of production capacity, premature part failure, and may void all warranties. Remote condensers must be installed per local building...

Open the catalog to page 9

EF and EMF Series Electrical and Plumbing Requirements Electrical and Plumbing Requirements: 32, 38 and 48 inch Cabinets TOP VIEW ICE-O-MATIC SIDE VIEW FRONT VIEW REAR VIEW Page 5

Open the catalog to page 10

EF and EMF Series Electrical and Plumbing Requirements Electrical and Plumbing Requirements: EMF 450, 800 1106 Air, Water and Remote Page 6

Open the catalog to page 11

EF and EMF Series Electrical and Plumbing Requirements Electrical and Plumbing Requirements: EMF2300 Air, Water and Remote Page 7

Open the catalog to page 12

EF and EMF Series How the ICE Machine Works A general description of how the Ice-O-Matic Flaker works is given below: Whenever the ON/OFF switch is in the ON position (and the bin control and safety controls are closed) the machine will continuously make ice and deliver it into the storage bin. Water enters a reservoir through the float valve and is gravity fed into the evaporator barrel through an opening in the bottom of the barrel. Water fills the evaporator to the same level as the water in the reservoir. This level is maintained by a float valve which stops the flow of water into the...

Open the catalog to page 13All Ice-O-Matic catalogs and technical brochures

-

CIM0530/0535

2 Pages

-

CIM0430/0436/0435

2 Pages

-

CIM0330/0335

2 Pages

-

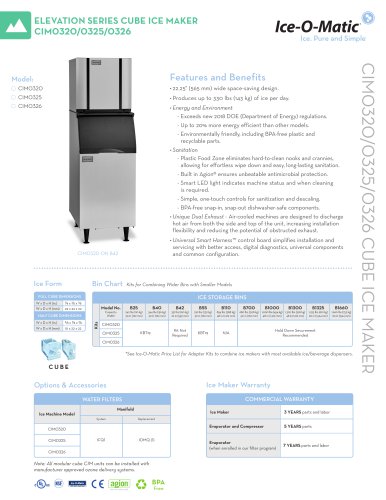

CIM0320/0325/0326

2 Pages

-

CIM2046/2047

2 Pages

-

GEM0450

2 Pages

-

GEM0650/0655

2 Pages

-

MFI1256/1255

2 Pages

-

GEM2006

2 Pages

-

Ec03 IceTM

2 Pages

-

The Elevation series

2 Pages

-

B110 SLOPE-FRONT BIN

1 Pages

-

ICEU86

2 Pages

-

GEM0956/0955

2 Pages

-

ICEU106

2 Pages

-

ICE1806/1807

2 Pages

-

Elevation Series

2 Pages

-

ICEU46

2 Pages

-

ICEU36

2 Pages

-

ICEU56

2 Pages

-

ICEU186

2 Pages

-

ICEF155

2 Pages

-

GEM1306

2 Pages

-

Full Line

20 Pages

-

ICE0726 / ICE0926

2 Pages

-

EC1807 - B2 Series Cuber

102 Pages

-

CD40030 Dispenser

21 Pages

-

ICE0726

2 Pages

-

MFI0800/0805

2 Pages

-

IOD200

2 Pages

-

IOD250

2 Pages

-

IOD150

2 Pages

-

WATER FILTERS

2 Pages

-

Full-Line Product Brochure

20 Pages

-

MFI1256/1255-Flake Ice Maker

2 Pages

-

MFI0800/805-Flake Ice Maker

2 Pages

-

MFI0500-Flake Ice Maker

2 Pages

-

Storage Bins

2 Pages

-

Cube Ice Brochure

8 Pages

-

GEMU090 Series

16 Pages

Archived catalogs

-

MFI1506

2 Pages

-

HIS Line

2 Pages

-

MFI0805

30 Pages

-

B100 Storage Bin - Parts Manual

13 Pages

-

MFI2406-Flake Ice Maker

2 Pages

-

GEM-MFI Series

68 Pages

-

B, EC and ECP Séries

102 Pages

-

MODEL-GEMD270A

28 Pages

-

GEM-MFI Series

30 Pages

-

Ice-O-Matic Full Line Brochure

24 Pages