Catalog excerpts

SERVICE AND INSTALLATION MANUAL PEARL ICE® / WATER DISPENSER MODEL-GEMD270A Ice-O-Matic 11100 East 45th Ave Denver, Colorado 80239 Part Number 9081407-01 Print Date 9/09

Open the catalog to page 1

SERVICE PARTS MANUAL 22 INCH WIDE ICE SERIES CUBERS MODEL-ICE0320, ICE0520 Includes 50Hz. Units ICE-O-Matic 11100 East 45th Ave Denver, Colorado 80239 Part Number 9081297-01 PD04/02 Rev1/05

Open the catalog to page 2

GEMD270A INTRODUCTION This manual provides the specifications and the step-by-step procedures for the installation, start-up, operation, maintenance and cleaning for the Ice-O-Matic GEMD270A counter top Pearl Iceâ dispenser. NOTE: To retain the safety and performance built into this ice machine, it is important that installation and maintenance be conducted in the manner outlined in this manual. Ice-O-Matic 11100 East 45th Ave. Denver CO 80239 800-423-3367 Table of Contents SPECIFICATIONS · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 2...

Open the catalog to page 3

GEMD270A SPECIFICATIONS GEMD270A: Ice Maker Dispenser, TouchFree, 200 lb ice making capacity, Pearl Ice â, 12 lb storage To keep your Ice-O-Matic Pearl Ice â Dispenser at peak performance levels, periodic maintenance checks must be carried out as indicated in this manual. Important Operating Requirements: Min Max o Air Temperature 50 F 100oF Water Temperature 40oF 95oF Water Pressure 20 psi 70 psi Electrical voltage variations from voltage rating specified on nameplate -10% +10% MACHINE SPECIFICATIONS Model Cond. unit Air GEMD270A Basic electrical 115/60/1 Cabinet Size Finish 34 13/32” high...

Open the catalog to page 4

GEMD270A CABINET DIAGRAMS Page 3

Open the catalog to page 5

GEMD270A GENERAL INFORMATION AND INSTALLATION LOCATION AND LEVELING UNPACKING AND INSPECTION 1. Call your authorized Ice-O-Matic Distributor or Dealer for proper installation. 2. Visually inspect the exterior of the packing and skid. Any severe damage noted should be reported to the delivering carrier and a concealed damage claim form filled in subject to inspection of the contents with the carrier’s representative present. 3. a) Cut and remove the plastic strip securing the carton box to the skid. WARNING: This Ice Dispenser is designed for indoor installation only. If the machine is...

Open the catalog to page 6

GEMD270A ELECTRICAL CONNECTIONS See data plate for current requirements to determine wire size to be used for electrical connections. All Ice-O-Matic ice machines require a solid earth wire. This Ice-O-Matic ice machine is supplied from the factory completely pre-wired and only needs to be plugged into a nearby 115 volt outlet. Make sure that the ice machine is connected to its own circuit and individually fused (see data plate for fuse size). The maximum allowable voltage variation should not exceed -10% and +10% of the data plate rating. Low voltage can cause faulty functioning and may be...

Open the catalog to page 7

GEMD270A WATER SUPPLY AND DRAIN CONNECTIONS GENERAL WATER DRAIN When choosing the water supply for the ice flaker, consideration should be given to: The recommended drain tube is a copper, rigid plastic or reinforced flexible tubing (supplied) with .75" (19mm) I.D. which runs to an open trapped and vented drain. When the drain is a long run, allow1/4" drop per foot. a) Length of run b) Water clarity and purity c) Adequate water supply pressure Note: Although soft, easily kinked vinyl tubing is not recommended for a drain, a short length of ¾” ID vinyl tubing is required to connect a rigid...

Open the catalog to page 8

GEMD270A FINAL CHECK LIST 1. Is the unit in a room where the ambient temperatures are within a minimum of 50°F even in winter months? 2. Is there at least a 6" clearance around the unit for proper air circulation? 3. Is the unit level? 4. Have all the electrical and plumbing connections been made, and is the water supply shut-off valve open? 5. Has the voltage been tested and checked against the data plate rating? 6. Has the water supply pressure been checked to ensure a flowing water pressure of at least 20 psi. 7. Check all refrigerant lines and conduit lines to guard against vibrations...

Open the catalog to page 9

GEMD270A OPERATING INSTRUCTIONS INITIAL START UP After having correctly installed the ice machine and completed the plumbing and electrical connections, perform the following “Start-up” procedure. Remove the control board inspection panel and cover to view the lights on the control board. A. Open the water supply line shutoff valve and turn the main switch on the power supply line to the ON position. The GREEN LED will glow to signal that unit is under power. B. After 3 minutes have elapsed – the stand by period – the unit starts operating by activating systems in following sequence: 1....

Open the catalog to page 10

GEMD270A INITIAL START UP CONTINUED NOTE: If the evaporating temperature has not dropped lower than 30° F within ten minutes of compressor start-up, the evaporating temperature sensor will detect the abnormal temperature and stop the unit operation. In this circumstance, the 3rd warning YELLOW LED will blink (Fig.3). After diagnosing and eliminating the cause of the poor evaporating temperature (insufficient refrigerant in the system, inoperative compressor or inoperative evaporator sensor), push the RESET BUTTON on the control board. Before resuming operation the unit will go through the...

Open the catalog to page 11

GEMD270A signaling that there is a full storage bin (Fig.6). After diagnosing and fixing the cause of the temperature rise, push the RESET BUTTON on the control board. Before resuming operation the unit will go through the usual 3 minute STAND-BY period. E. Check for the correct CUT-OUT and CUT-IN of the float reservoir water level sensors by shutting off the valve on the water supply line. This will cause a gradual decrease of the water level in the float reservoir and as soon as the level gets below the sensors, the flaker stops operating and the 5th YELLOW WARNING LED will glow to signal...

Open the catalog to page 12All Ice-O-Matic catalogs and technical brochures

-

CIM0530/0535

2 Pages

-

CIM0430/0436/0435

2 Pages

-

CIM0330/0335

2 Pages

-

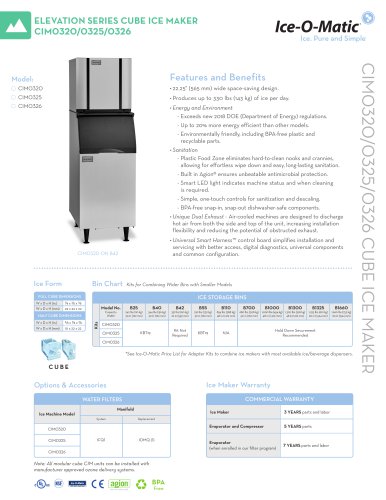

CIM0320/0325/0326

2 Pages

-

CIM2046/2047

2 Pages

-

GEM0450

2 Pages

-

GEM0650/0655

2 Pages

-

MFI1256/1255

2 Pages

-

GEM2006

2 Pages

-

Ec03 IceTM

2 Pages

-

The Elevation series

2 Pages

-

B110 SLOPE-FRONT BIN

1 Pages

-

ICEU86

2 Pages

-

GEM0956/0955

2 Pages

-

ICEU106

2 Pages

-

ICE1806/1807

2 Pages

-

Elevation Series

2 Pages

-

ICEU46

2 Pages

-

ICEU36

2 Pages

-

ICEU56

2 Pages

-

ICEU186

2 Pages

-

ICEF155

2 Pages

-

GEM1306

2 Pages

-

Full Line

20 Pages

-

ICE0726 / ICE0926

2 Pages

-

EC1807 - B2 Series Cuber

102 Pages

-

CD40030 Dispenser

21 Pages

-

ICE0726

2 Pages

-

MFI0800/0805

2 Pages

-

IOD200

2 Pages

-

IOD250

2 Pages

-

IOD150

2 Pages

-

WATER FILTERS

2 Pages

-

Full-Line Product Brochure

20 Pages

-

MFI1256/1255-Flake Ice Maker

2 Pages

-

MFI0800/805-Flake Ice Maker

2 Pages

-

MFI0500-Flake Ice Maker

2 Pages

-

Storage Bins

2 Pages

-

Cube Ice Brochure

8 Pages

-

GEMU090 Series

16 Pages

Archived catalogs

-

MFI1506

2 Pages

-

HIS Line

2 Pages

-

MFI0805

30 Pages

-

B100 Storage Bin - Parts Manual

13 Pages

-

MFI2406-Flake Ice Maker

2 Pages

-

GEM-MFI Series

68 Pages

-

B, EC and ECP Séries

102 Pages

-

GEM-MFI Series

30 Pages

-

Series 250 through 2306

20 Pages

-

Ice-O-Matic Full Line Brochure

24 Pages