Catalog excerpts

Technical Manual Electro-Mechanical Cubers Including Under Counter Models Also Covers Electro-Mechanical C Series Machines Manufactured After 1988 Mile High Equipment Company © Ice-O-Matic

Open the catalog to page 1

General Information Model and Serial Number Format A-2 Electrical & Mechanical Specifications A-3 Electrical and Plumbing Requirements A-9 Remote Condenser Installation A-10 Scheduled Maintenance Cleaning and Sanitizing Instructions B-l Troubleshooting Trees Troubleshooting Trees Table Of Contents C-2 Water System Water Distribution and Components D-l Refrigeration System Refrigeration Cycle and Components E-l Pump Down System E-8 Electrical System Compressor and Start Components F-2 Pump Down System F-10

Open the catalog to page 3

Ice-O-Matic provides this manual as an aid to the service technician in installation, operation, and maintenance of the electro- mechanical C, EC and ECP series cube ice machines. If used properly this manual can also help the service technician trou- bleshoot and diagnose most of the problems that may occur with the machine. The first two sections of mis manual provide general and maintenance information. The remainder of the manual beginning with section C provides troubleshooting and service information. Section C contains flow charts called troubleshooting trees. Page C-l provides...

Open the catalog to page 4

iBmml flimfemita / EC and ECP Series Model and Serial Number Format Model Numbers 1-Control system: C = Electro-mechanical C = Computerized <-Cabinet finish: P = Painted S — Stainless steel I-Condenser type: A = Air W = Water R = Remote 1-Cube size: H = Half F = Full J = Jumbo I_Approximate production in 24 hrs: (70°F/21°C air temp, and 50°F/10°C water temp.) Models beginning with "EC" Multiply X 10 Models beginning with "C" Multiply X 100 * Series: C = Cube ice machine EC = Environmental Cuber (uses HFC refrigerant) U = Under Counter Serial Number Date Code First letter in the serial...

Open the catalog to page 5

EC and ECP Series / Oiiiril lnformitSoini Electrical and Mechanical Specifications "C" Series / 60 Cycle Machines # = H (Half cube) or F (Full cube) * Rated Load Amps ** Use refrigerant charge specified on Serial Plate when charging system.

Open the catalog to page 6

\<®mml Iffufoirofilto / EC and ECP Series Electrical and Mechanical Specifications "ECSeries / 60 Cycle Machines

Open the catalog to page 7

EC and ECP Series / Otosral Opfomufco Electrical and Mechanical Specifications "EC" Series / 60 Cycle Machines # = H (Half cube) or F (Full cube) * Rated Load Amps ** Use refrigerant charge specified on Serial Plate when charging system. *** Machine not available at time of printing.

Open the catalog to page 8

itinisrs)! Dnlibinrnflltioini / EC and ECP Series Electrical and Mechanical Specifications "ECP'Series / 60 Cycle Machines # = H (Half cube) or F (Full cube) * Rated Load Amps ** Use refrigerant charge specified on Serial Plate when charging system. *** Machine not available at time of printing.

Open the catalog to page 9

EC and ECP Series / Ssflwal lififomaiOT Electrical and Mechanical Specifications "C'Series / 50 Cycle Machines # = H (Half cube) or F (Full cube) * Rated Load Amps ** Use refrigerant charge specified on Serial Plate when charging system.

Open the catalog to page 10

Electrical and Mechanical Specifications "EC" series / 50 Cycle Machines # = H (Half cube) or F (Full cube) * Rated Load Amps ** Use refrigerant charge specified on Serial Plate when charging system. *** Machine not available at time of printing.

Open the catalog to page 11

EC and ECP Series / Oemi©ril lofonnniioffl Installation Guidelines For proper operation of the ICE-O-MATIC ice machine the following installation guidelines must be followed. Failure to do so may result in loss of production capacity, premature part failures, and may void all warranty. Installation should be performed by a qualified service technician. Ambient Operating Temperatures Minimum operating temperature: 50° F (10° C) Maximum operating temperature: 100° F (38° C) Clearance Requirements Self contained air cooled machines must have a minimum of 6" (15 cm) of clearance at the rear and...

Open the catalog to page 12

ieimsffil lififoTOilta / EC and ECP Series Electrical and Plumbing Requirements Electrical and Plumbing Sizing 1 Electrical Inlet: 7/8" knock-out for remote or ECP water cooled 2 Electrical Inlet: 7/8" in knock-out 3 Water inlet fitting: 3/8" FPT 4 Purge drain: 3/4" FPT (some models may use 9/16"I.D. plastic tubing) 6 Water cooled condenser drain fitting: 1/2" FPT 7 Remote condenser discharge line fitting: 1/2" quick-connect 8 Remote condenser liquid line fitting: 3/8" quick-connect 9 Water cooled condenser inlet fitting: 1800 Series 1/2" FPT All other models 3/8" FPT

Open the catalog to page 13

EC and ECP Series / Otwal iinfoiraaita Remote Condenser Installation For proper operation of the ICE-O-MATIC ice machine the following installation guidelines must be followed. Failure to do so may result in loss of production capacity, premature part failures, and may void all warranty. Installation Guidelines • Ambient operating temperatures: -20° F (-28° C) to 110° F (43° Q * Maximum refrigerant line length: 40 ft. (12.2 m) • Maximum vertical rise: 15ft. (4.6 m) • Minimum condenser height C66/65, EC606/605 and ECP606, condensers must not be installed more than 6' (1.83 meters) below the...

Open the catalog to page 14

mmml M©<m@Mm I EC and ECP Series General Operation A general description of how the C, EC and ECP series cubers work is given below. The remainder of the manual provides more detail about the operation and troubleshooting of these machines. With the ICE/OFF/WASH switch in the ICE position, the compressor, water pump, and condenser fan motor (air cooled machines only) will energize starting the freeze cycle. During the freeze cycle water is circulated over the evaporator(s) where the ice cubes are formed. When the suction pressure has pulled down to the proper cut-in pressure of the timer...

Open the catalog to page 15

idftxsdyfled IMaimfeiiniara / EC and ECP Series Electrical shock and/or injury from moving parts inside this machine can cause serious injury. Disconnect electrical supply to machine prior to performing any adjustments or repairs. Failure to perform the required maintenance at the frequency specified will void warranty coverage in the event of a related fail- To insure economical, trouble free operation of the machine, the following maintenance is required every 3 months. Maintenance Procedure 1. Clean the ice-making section per instructions below. Cleaning should be preformed a minimum of...

Open the catalog to page 17All Ice-O-Matic catalogs and technical brochures

-

CIM0530/0535

2 Pages

-

CIM0430/0436/0435

2 Pages

-

CIM0330/0335

2 Pages

-

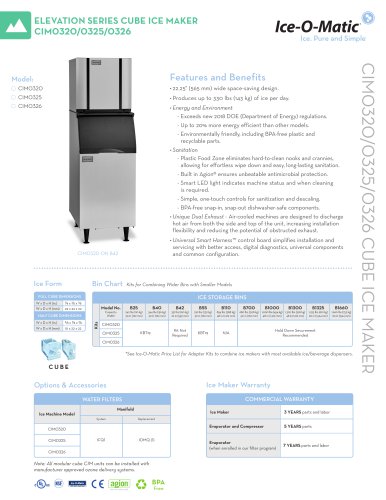

CIM0320/0325/0326

2 Pages

-

CIM2046/2047

2 Pages

-

GEM0450

2 Pages

-

GEM0650/0655

2 Pages

-

MFI1256/1255

2 Pages

-

GEM2006

2 Pages

-

Ec03 IceTM

2 Pages

-

The Elevation series

2 Pages

-

B110 SLOPE-FRONT BIN

1 Pages

-

ICEU86

2 Pages

-

GEM0956/0955

2 Pages

-

ICEU106

2 Pages

-

ICE1806/1807

2 Pages

-

Elevation Series

2 Pages

-

ICEU46

2 Pages

-

ICEU36

2 Pages

-

ICEU56

2 Pages

-

ICEU186

2 Pages

-

ICEF155

2 Pages

-

GEM1306

2 Pages

-

Full Line

20 Pages

-

ICE0726 / ICE0926

2 Pages

-

CD40030 Dispenser

21 Pages

-

ICE0726

2 Pages

-

MFI0800/0805

2 Pages

-

IOD200

2 Pages

-

IOD250

2 Pages

-

IOD150

2 Pages

-

WATER FILTERS

2 Pages

-

Full-Line Product Brochure

20 Pages

-

MFI1256/1255-Flake Ice Maker

2 Pages

-

MFI0800/805-Flake Ice Maker

2 Pages

-

MFI0500-Flake Ice Maker

2 Pages

-

Storage Bins

2 Pages

-

Cube Ice Brochure

8 Pages

-

GEMU090 Series

16 Pages

Archived catalogs

-

MFI1506

2 Pages

-

HIS Line

2 Pages

-

MFI0805

30 Pages

-

B100 Storage Bin - Parts Manual

13 Pages

-

MFI2406-Flake Ice Maker

2 Pages

-

GEM-MFI Series

68 Pages

-

B, EC and ECP Séries

102 Pages

-

MODEL-GEMD270A

28 Pages

-

GEM-MFI Series

30 Pages

-

Series 250 through 2306

20 Pages

-

Ice-O-Matic Full Line Brochure

24 Pages