Catalog excerpts

SoilTain® Dewatering High-flow Sludge Dewatering System

Open the catalog to page 1

SoilTain sludge dewatering applications The direct removal of waterlogged sediments and residues from mines, industrial plants, construction sites and sewage works often involves high cost and effort. It therefore tends to be more economical to dewater the sludge prior to any disposal operation. SoilTain tubes offer a fast and cost-effective dewatering solution that is suitable for many different sludge types. Sediments Sediments, which comprise a mixture of mineral and organic material, are often polluted by TBT, PCB and heavy metals such as Mercury or Lead. Mining residuals Mining...

Open the catalog to page 2

The first step is to remove the sludge. Sediments, for instance, can be extracted by a suction dredger. Other sludges may be continuously produced as a by-product. The sludge is conditioned through the addition of a flocculating agent. This causes the particles suspended in the water to agglomerate together into larger flakes, so-called flocs. The gravity drainage process ensures the steady removal of water from the sludge in the technical textile tube. The specific opening size of the high-performance woven textile ensures retention of the solid fraction of the Through the steady process...

Open the catalog to page 3

The ideal solution SoilTain Dewatering Tubes SoilTain tubes offer a fast and economical means of sludge dewatering. The large-format tubes offer high process capacity and dewatering performance while taking up relatively little space. This helps to speed up progress on site. The tubes, which are made of purpose-developed, high-performance woven technical textile material, can be stacked to increase storage capacity still further. Cost savings are also achieved by the lower machinery and associated power and fuel demands for dewatering and transportation of the sludge from the site. The...

Open the catalog to page 4

Three crucial factors \ Filling capacity | m3/day r i i Process time In addition to the filling operation, the dewatering process also includes the subsequent volume reduction phase. The cake, i.e. dry mass, remaining at the end of this process is then suitable for disposal. The short process time achieved by SoilTain could only be matched by mechanical means through the use of some 12 centrifuges, 22 chamber filter presses or 30 belt filter presses. The diagram presents a comparison based on the use of a single centrifuge or press. \ Total cost | I I i Project costs Even the most efficient...

Open the catalog to page 5

Application example: Sediments Dockside maintenance dredging Tributyltin (TBT) was banned worldwide in 2003. It had previously been used as an anti-fouling agent in many ship hull coatings to prevent the growth of marine organisms. As a result, the sediments at Husum docks in northern Germany had been heavily polluted by the toxic chemical. The maintenance dredging operations involved the extraction of 50,000 m3 of polluted dock silt by cutter-suction dredger. To optimise the use of the small area available for dewatering, the SoilTain Dewatering Tubes were stacked two layers high. The...

Open the catalog to page 6

SoilTain® is a registered trademark of HUESKER Synthetic GmbH. HUESKER Synthetic is certified to ISO 9001, ISO 14001 and ISO 50001. E-mail: info@HUESKER.de Internet: www.HUESKER.com □ HUESKERIdeen. Ingenieure. Innovationen. 07/16 B Copyright by HUESKER Synthetic GmbH, Gescher

Open the catalog to page 7All Huesker catalogs and technical brochures

-

Agritec®

4 Pages

-

Basetrac®

11 Pages

-

Handling Waterbodies Responsibly

13 Pages

-

Incomat®

9 Pages

-

eco LINE

3 Pages

-

Fortrac® 3D Geogrid

5 Pages

-

Basetrac

11 Pages

-

Tektoseal Sand

2 Pages

-

Tektoseal Clay

3 Pages

-

NaBento

6 Pages

-

HaTe

4 Pages

-

Tektoseal® Sand

2 Pages

-

Ringtrac®

9 Pages

-

HaTelit® BL

4 Pages

-

Base Reinforcement - Segment

8 Pages

-

SamiGrid

4 Pages

-

SoilTain® Dewatering Tubes

4 Pages

-

Incomat

16 Pages

-

CANAL3

8 Pages

-

Stabilenka

6 Pages

-

Robutec

4 Pages

-

HaTe® Nonwowen

4 Pages

-

Geosynthetics

12 Pages

-

COVERTEC - Biogas and Manure

8 Pages

-

Tektoseal®

4 Pages

-

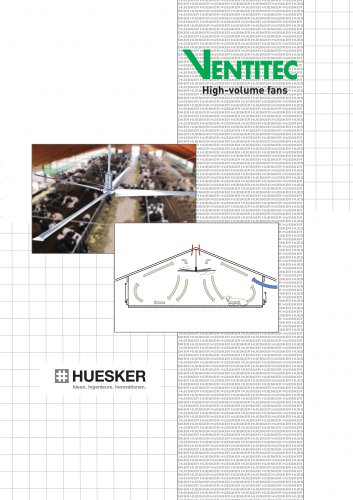

Ventitec

6 Pages

-

Lubratec

12 Pages

-

AGRAR

8 Pages

-

HaTelit ®

12 Pages

-

Fortrac ®

12 Pages

-

Fortrac 3D ®

6 Pages

-

Fornit ®

6 Pages

-

Comtrac ®

4 Pages