Catalog excerpts

B The Safe Choice for a Safe Future Geosynthetics for Roads and Pavements Ideen. Ingenieure. Innovationen.

Open the catalog to page 1

Geosynthetics which endure – like our promises.

Open the catalog to page 2

HUESKER – an experienced partner that understands your needs. As geosynthetic specialists with a 150-year manufacturing track record, we have helped to shape the history of road and pavement engineering. Our engineers, customer consultants and manufacturing staff are all equipped to tackle projects which impose a wide diversity of requirements. However complex the project, we have always abided by the principle of delivering no-nonsense solutions that are closely tailored to our customers‘ specific needs. We are conscious that the many physical tonnes of loads carried by our in service...

Open the catalog to page 4

KEY DATA HUESKER products for Roads and Pavements meet all the requirements of: • • • • • • • EN ISO 9001 EN ISO 17025 EN ISO 14001 EN 15381 DIN 18200 CE marking IVG (German Geosynthetics Industry Association) • and other certification systems

Open the catalog to page 6

Guaranteed quality – a solid foundation for safety and stability. Needless to say, your projects are absolutely safe in our expert and experienced hands. Yet we fully understand customers who prefer to apply the “Trust But Verify” principle. Our products are subject to a continuous process of research, development and testing. The quality of our products and services is assured by a comprehensive monitoring, certification and external surveillance regime. Our high-performance, state-of-the-art production lines enable us to respond promptly and flexibly to customers‘ wishes, while...

Open the catalog to page 7

“Hamburg Airport” project: Strengthening of runway shoulders with Fortrac® KEY DATA • Approx. 3,500 m long, 45 m wide runway shoulders • Double-layer assembly with biaxial Fortrac® geogrids • Tensile strengths ranging between 60 and 120 kN/m, as required Airport operator Flughafen Hamburg GmbH (FHG) carried out a project to raise the bearing capacity of the 45 m wide shoulders on either side of the runway in line with the Aerodrome Design Manual of the International Civil Aviation Organization. Airport Pavements The shoulders were required to be strong enough to prevent any aircraft that...

Open the catalog to page 8

KEY DATA • Rehabilitation of approx. 4 km long, 40 m wide runway • Use of HaTelit® C 40/17 geogrids Rehabilitation of Asphalt Pavements “Thumrait Airbase” project, Oman: Extension of service life with HaTelit® The runway at the Thumrait Airbase in Oman was rehabilitated in 2009. The existing construction comprised a concrete pavement with an 18 cm asphalt overlay. After several years of service, the expansion joint in the concrete slabs had propagated as cracks to the pavement surface, leaving no alternative but to repair the runway. The first step in the rehabilitation was to mill off a 14...

Open the catalog to page 9

“A 52 motorway” project: Pavement rehabilitation using HaTelit® The repairs to the damaged pavement surfacing on the section of Germany‘s A 52 motorway between the Neersen and Mönchengladbach interchanges were carried out in July 2009. To ensure the long-term retardation of reflective cracking, which had been the root cause of the damage, and increase the service life of the rehabilitated pavement, Landesbetrieb Straßenbau NRW – the state enterprise responsible for highway maintenance in the German State of North Rhine-Westphalia – opted for the use of HUESKER‘s HaTelit® C 40/17 asphalt...

Open the catalog to page 10

KEY DATA • Approx. 40,000 m2 asphalt reinforcement • Grid laid on existing asphalt base course • Overlaying with 5 cm binder and 3.5 cm SMA surface course • Use of HaTelit® C 40/17 reinforcement Rehabilitation of Asphalt Pavements Work sequence: The first step was to mill off the existing surface course and part of the binder course. HaTelit® C 40/17 asphalt reinforcement was then laid over the entire milled surface by a specialist contractor in accordance with the HaTelit® installation instructions. The installed grid was subsequently overlaid with a 5 cm (0/16S) asphalt binder course and...

Open the catalog to page 11

“Münster-Hamm railway line upgrade” project: Reinforcement of rail section with Comtrac® KEY DATA • Improvement of track subgrade through installation of Comtrac® 50/50 B25 • Works performed with automatic SVV 100 sand distributing and compacting machine • 20 km rail section length Plans to raise the maximum permissible speeds on the Münster-Hamm rail section to over 160 km/h necessitated a comprehensive rehabilitation of the existing track bed. To ensure the future stability of the permanent way and track skeleton, it was necessary to increase the bearing capacity of the subgrade. This...

Open the catalog to page 12

KEY DATA • Construction of crane base with access routes • Use of Fornit® geogrids Working Platforms / Wind Turbines “Sheldon Wind Farm” project: Base reinforcement using Fornit® Sheldon Wind Farm produces wind energy for the town of Sheldon in Wyoming County in the US state of New York. With a maximum output of 129 MW, the wind farm generates enough clean, renewable energy to power some 60,000 households per year. Overall, the project comprises 75 wind turbines, most of which are installed on agricultural land on an approx. 550 m high plateau. At this altitude, the turbines are exposed to...

Open the catalog to page 13

Our portfolio – products that offer fundamental benefits. Whatever ground stabilization challenges you face, HUESKER will supply you with products that embody decades of experience and expertise. In developing our geosynthetics, we have always endeavoured to combine straightforward installation with flexible application. Longevity is a further key issue in production. Ever since the company was founded, over 150 years ago, our manufacturing processes have been subject to continuous, across-the-board technical optimization so as to furnish our customers with premium-quality products at all...

Open the catalog to page 14All Huesker catalogs and technical brochures

-

Agritec®

4 Pages

-

Basetrac®

11 Pages

-

Handling Waterbodies Responsibly

13 Pages

-

Incomat®

9 Pages

-

eco LINE

3 Pages

-

Fortrac® 3D Geogrid

5 Pages

-

Basetrac

11 Pages

-

Tektoseal Sand

2 Pages

-

Tektoseal Clay

3 Pages

-

SoilTain Dewatering

7 Pages

-

NaBento

6 Pages

-

HaTe

4 Pages

-

Tektoseal® Sand

2 Pages

-

Ringtrac®

9 Pages

-

HaTelit® BL

4 Pages

-

Base Reinforcement - Segment

8 Pages

-

SamiGrid

4 Pages

-

SoilTain® Dewatering Tubes

4 Pages

-

Incomat

16 Pages

-

CANAL3

8 Pages

-

Stabilenka

6 Pages

-

Robutec

4 Pages

-

HaTe® Nonwowen

4 Pages

-

Geosynthetics

12 Pages

-

COVERTEC - Biogas and Manure

8 Pages

-

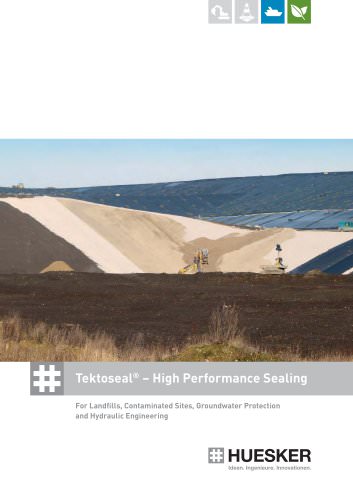

Tektoseal®

4 Pages

-

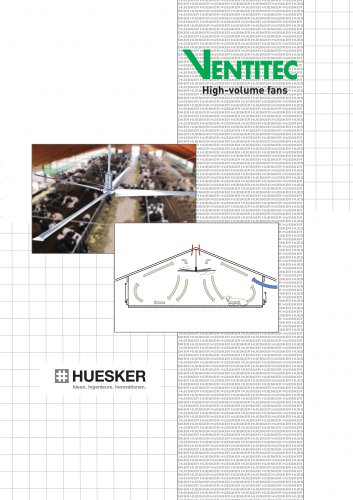

Ventitec

6 Pages

-

Lubratec

12 Pages

-

AGRAR

8 Pages

-

HaTelit ®

12 Pages

-

Fortrac ®

12 Pages

-

Fortrac 3D ®

6 Pages

-

Fornit ®

6 Pages

-

Comtrac ®

4 Pages