Catalog excerpts

Plate Heat Exchangers for Heat Recovery in Ventilation Systems Handbook for Design, Installation and Operation

Open the catalog to page 1

Special plate profile The plate surface profile has been designed and extensively tested to provide maximum efficiency. As a result, Hoval cross flow plate heat exchangers yield a dry heat recovery efficiency of more than 80 %. Recirculation bypass option With the exchanger recirculation bypass option the AHU recirculation mixing box is not required with resulting cost savings. Plate crimping The plates are sealed with a double sheet metal fold ensuring good exchanger rigidity and minimizing leakage. Stainless steel exchanger option There are a wide range of options including stainless...

Open the catalog to page 2

1 Principle and Operation_________4 1.1 Heat transmission 1.2 Leakage 1.3 Moisture transmission 1.4 Condensation 1.5 Temperature profile 1.6 Frost limit 1.7 Heat recovery efficiency 1.8 Pressure drop 1.9 Pressure difference 1.10 Hygiene 2 Performance Control___________8 3 Construction__________________9 3.1 Exchanger package in design S 3.2 Exchanger package in designs F and P 3.3 Plate connection 3.4 Casing of designs S and F 3.5 Casing of design P 4 Model Range________________ 11 4.1 Designs 4.2 Series 4.3 Exchanger sizes 4.4 Plate spacing 4.5 Exchanger width...

Open the catalog to page 3

Heat recovery reduces costs and protects the environment Hoval plate heat exchangers are important ele ents in saving energy in industrial and m commercial buildings such as hotels, hospitals, sports halls, office buildings, seminar rooms, swimming pools, drying pro esses, paint spray c booths and extraction plants. They are used in air handling units, duct ork systems and in process w technology. This investment pays off in several ways: ■■ Lower energy consumption ■■ Lower investment for heat generation and distribution ■■ Less damage to the environment No cross-contamination of the...

Open the catalog to page 4

Materials which suit the applications Three series are available to suit a wide variety of applications: ■■ Series V (standard ) Designs S and F with the exchanger package of aluminium and the casing of aluminium extrusions and Aluzinc sheet steel. Design P with the exchanger package and casing of stainless steel. ■■ Series G (corrosion-protected) Designs S and F with coated exchanger package and casing. ■■ Series T ( igh temperature) h Designs S, F and P with a special sealing agent resistant to temperatures up to 200 °C. Reliable in operation Hoval plate heat exchangers have no oving...

Open the catalog to page 5

1 Principle and Operation Hoval plate heat exchangers operate within the guidelines for heat recovery (e.g. Eurovent 10, VDI 2071) as recuperators with joint faces (category 1). The heat releasing and heat absorbing air streams pass along the joint face, through which the heat is directly transmitted. Supply and extract air must therefore be brought together and flow through the heat exchanger. Fig. 1: The air streams, separated by thin plates, pass each other. 1.1 Heat transmission Hoval plate heat exchangers operate on the cross-flow principle. Heat is transmitted via the plates from...

Open the catalog to page 6

The two air streams are separated in the Hoval plate heat exchanger and transmission of moisture is therefore not possible. This is a special advantage when moisture is removed with the warm air, e.g. in swimming pools, drying processes, etc. With the cross-flow heat exchanger, the air streams are not heated and cooled evenly. This means that the temperatures vary along the cross section of the air stream. The computer graphic, calculated by the finite element method, shows this. Because of the temperature variation the verification of the efficiency under operating conditions is...

Open the catalog to page 7

1.7 Heat recovery efficiency If the warm air stream is severely cooled down, it is not only possible for condensation to form, but also to freeze. The cold air temperature at which freezing starts, is called the 'frost limit'. In practice this is rare as several factors must coincide: ■■ Very low temperature of the cold air stream ■■ Cold air volume is greater than warm air volume. ■■ High efficiency of the exchanger ■■ Relatively little condensation ■■ The condensation cannot drain away easily. If several of these circumstances coincide the plate heat exchanger can ice up starting at the...

Open the catalog to page 8

comparison with other constructions, the following should be considered when designing: ■ The pressure difference in the heat exchanger should be ■ The pressure gradient and thus leakage should be from the supply air to the extract air side. The internal pressure difference also may cause a deforma- tion of the plates. The plate spacing is then narrowed and/ or widened, resulting in corresponding variations of pressure drop. Extensive tests have shown that the influence of defor- mation depends on the plate spacing (see diagram 1). The permitted pressure difference between the two air This...

Open the catalog to page 9

Performance Control 2 Performance Control The Hoval plate heat exchanger operates as a temperature moderator between the two air streams. The direction of the heat transmission is of no consequence, i.e. depending on the temperature difference between extract and fresh air, either heat recovery or cool recovery takes place. Therefore performance control of the Hoval plate heat exchanger is not necessary when the extract air temperature is identical to the desired room temperature. In this case, the outside temperature is always either heated or cooled through the plate heat exchanger in...

Open the catalog to page 10

3.2 Exchanger package in designs F and P Hoval plate heat exchangers consist of the exchanger package and the casing. Sizing of the exchanger package (plate size and plate spacing) depends mainly on the air flowrate. To achieve an optimum result with regard to heat recovery efficiency, pressure drop and costs Hoval manufactures different package designs: ■■ design S with plate spacings from 2 mm to 9 mm ■■ designs F and P with plate spacings from 4 mm to 12 mm 3.1 Exchanger package in design S The exchanger package consist of specially formed aluminium plates. Their profile with V-shaped...

Open the catalog to page 11All Hoval Italia catalogs and technical brochures

-

Spare parts list

10 Pages

-

Hoval HomeVent®

1 Pages

-

Gotthard

4 Pages

-

PressVal Intermediate

2 Pages

-

Ceramic Filter

8 Pages

-

CT-plus

4 Pages

-

Max-3

8 Pages

-

TransTherm

12 Pages

-

RoofVent Design Handbook

280 Pages

-

UltraSol and UltraSol eco

115 Pages

-

BioLyt (8-36)

54 Pages

-

ServeLine

8 Pages

-

Modul-plus

4 Pages

-

PowerBloc CHP

8 Pages

-

Product overview

2 Pages

-

BioLyt Wood Pellet Boiler

12 Pages

-

UltraGas® Condensing Gas Boiler

12 Pages

-

SR-plus brochure

8 Pages

Archived catalogs

-

BioLyt. 10-26

10 Pages

-

AgroLyt

14 Pages

-

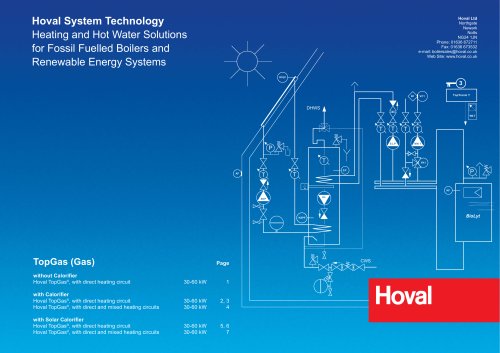

TopGas 30-60

9 Pages

-

Cosmo

10 Pages

-

Uno3-cosmo TCAF

7 Pages

-

MultiJet®

22 Pages