Catalog excerpts

TWO COMPONENTS EPOXY ADHESIVE RELIABLE Proven durability evidenced by 30 years of use in timber construction. HIGH PERFORMANCE High-performance two-components epoxy adhesive. The strength of the connection is dependent on the timber due to the adhesives over-performance. VERSATILE In cartridges for practical and fast use, in 3 litre and 5 litre sizes for larger volume joints. CHARACTERISTICS FOCUS TYPES RANGE APPLICATION structural gluing joints with rods, joints with perforated or sandblasted plates 5 products to adapt to all installation requirements applicable by spray, brush, percolation or spatula depending on viscosity VIDEO Scan the QR Code and watch the video on our YouTube channel MATERIAL Two components epoxy adhesive. FIELDS OF USE Shear joints, axial action and moment achievable on • solid timber and glulam • CLT • concrete 146 | XEPOX | EPOXY ADHESIVES AND HOOKED PLA

Open the catalog to page 1

STRUCTURAL Ideal for creating rigid multi-directional joints. STATIC CONSOLIDATION Can be used to rebuild “timber material” in combination with metal rods and other materials. EPOXY ADHESIVES AND HOOKED PLATES | XEPOX | 14

Open the catalog to page 2

CODES AND DIMENSIONS DRUMS ADDITIONAL PRODUCTS - ACCESSORIES CODE mixing nozzle APPLICATIONS XEPOX P - primer Two-components epoxy adhesive with extremely low viscosity and high wetting properties for structural reinforcments through carbon or glass fibre textures. Useful to protect sanded metal sheets SA2,5/ SA3 (ISO 8501) and to realize FRP (Fiber Reinforced Polymers) bits. Applicable by roller, spray and brush. Shelf life 36 months in the original unopened packaging, at temperatures between +5°C and +30°C. Component A classification: Eye Irrit. 2; Skin Irrit. 2; Skin Sens. 1; Aquatic...

Open the catalog to page 3

TECHNICAL FEATURES Properties Stoichiometric volume ratio (A/B)(1) Working life of the mixture Application temperature (maximum relative moisture 90%) Suggested thickness Normal adhesion tension σ Slant shear strength σ 0 50° Slant shear strength σ 0 60° Slant shear strength σ 0 70° Unitary breaking load in compression(3) Thermal expansion coefficient (ranging between -20°C / +40°C) Unitary shear strength by punch tool(4) Elastic modulus in compression The components are packaged in pre-measured quantities, ready to use. The ratio is by volume (not weight). It is best not to use more than...

Open the catalog to page 4

APPLICATION AND CONSERVATION TEMPERATURE ADHESIVE CONSERVATION Epoxy adhesives must be maintained at moderate temperature levels (approximately +16°C/+20°C) both in winter and summer until the moment they are used. Do not store the package in cold temperature environments, as it may increase the viscosity and hinder the pouring and the cartridge extrusion. Do not leave the package exposed to direct sunlight, as heat reduces the polymerisation times. +16°C/+20°C ADHESIVE APPLICATION The advised ambient application temperature is > + 10 °C. If the temperature is too cold, it will be necessary...

Open the catalog to page 5

MOMENT JOINTS WITH PLATES PREPARATION OF METALLIC SUPPORTS The metallic bits reinforcing the joints must be cleaned and ungreased. Smooth sheets must be treated with grade SA2,5/SA3 sanding and then protected through a layer of XEPOX P to avoid their oxidation. Especially during hot seasons, it is necessary to protect the metallic surfaces from direct sunlight. PREPARATION OF TIMBER SUPPORTS Close to the vertical edges, apply continuous strips of adhesive paper tape at about 2÷3 mm from the edge. Next, apply a continuous bead of acetic silicone and apply pressure so that it also adheres to...

Open the catalog to page 6

XEPOX EPOXY ADHESIVE A HISTORICAL FAMILY OF PRODUCTS FOR JOINTS BETWEEN TIMBER ELEMENTS, ABLE TO GUARANTEE AN EXCELLENT RESTORATION OF STRENGTH AND STIFFNESS XEPOX epoxy adhesives are two-component resins specifically formulated to penetrate the microstructure of wood and adhere to it with great effectiveness, and to reduce the typical resin crystallization. The mixture of components A and B causes an exothermic reaction (heat development) and, once hardened, forms a three-dimensional structure with exceptional properties, such as: durability over time, interaction with no humidity,...

Open the catalog to page 7

JOINTS WITH GLUED RODS The indications contained in DIN 1052:2008 and in the Italian standards CNR DT 207:2018 are reported. MINIMUM DISTANCES FOR RODS TENSION Rods glued // to the fibre a2 SHEAR Rods glued // to the fibre SHEAR Rods glued The minimum insertion length is: lmin = max CALCULATION METHOD TENSILE STRENGTH The tensile strength of a rod of diameter d is equal to: steel failure The effective area considers a square of timber with a maximum side of 6d; the area is reduced for smaller distances between the elements or from the edge. timber shear failure timber tensile strength =...

Open the catalog to page 9

SHEAR STRENGTH The shear strength of a rod can be calculated using the well-known Johansen's formulas for bolts with the following measures. For rods glued perpendicularly to the fibre, the bearing stress strength can be increased by up to 25%. fh,k = fh,k,// = 10% fh,k, The bearing stress strength for rods glued parallel to the fibre is 10% of the value perpendicular to the fibre. The hollow effect is evaluated as the strength given by the extraction bonding (failure b). To obtain the strength of a rod bonded at an α angle, it is permitted to interpolate linearly between the strength...

Open the catalog to page 10

MOMENT JOINTS WITH PLATES CALCULATION MODE | HEAD SECTION The stresses due to the moment and the axial action are determined by homogenizing the materials of the section, in the hypothesis of conservation of the flat sections. The shear stress is absorbed only by the plates. It is also necessary to check the stresses acting on the timber section net of the grooved sections. CALCULATION METHOD | MOMENT DISTRIBUTION ON THE STEEL-WOOD-ADHESIVE INTERFACE The moment is distributed over the number of interface surfaces and then broken down into stresses, considering both the polar inertia around...

Open the catalog to page 11All HOLZ TECHNIC catalogs and technical brochures

-

TITAN F

9 Pages

-

TITAN N

17 Pages

-

TITAN PLATE C

8 Pages

-

TITAN PLATE T

4 Pages

-

UV-T

9 Pages

-

WHT PLATE T

4 Pages

-

FACADE BAND UV

2 Pages

-

WINDOW BAND

2 Pages

-

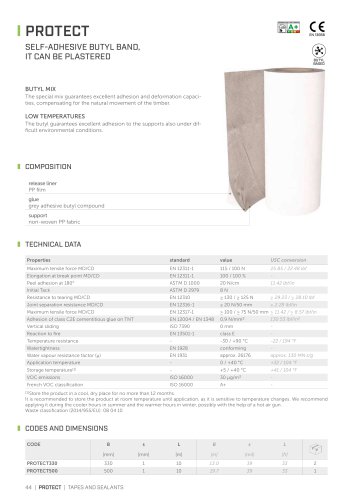

PROTECT

2 Pages

-

LEVEL BAND

1 Pages

-

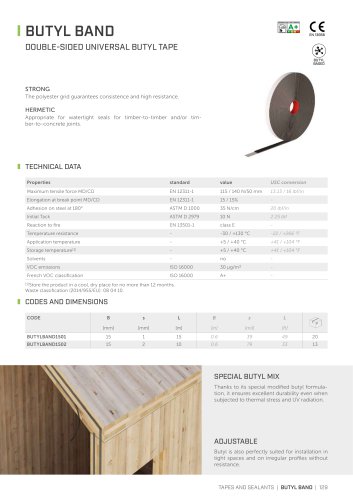

BUTYL BAND

1 Pages

-

ALU BAND

1 Pages

-

AIR GLUE

2 Pages

-

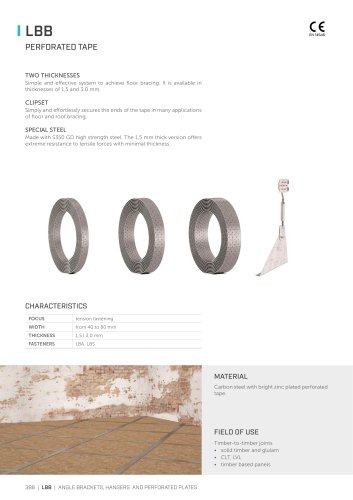

LBB

6 Pages

-

WHT PLATE C

8 Pages

-

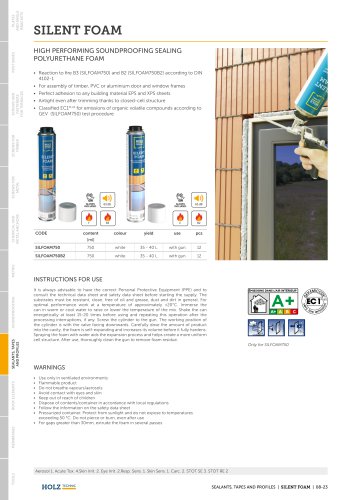

SILENT FOAM

2 Pages

-

GROUND BAND

4 Pages

-

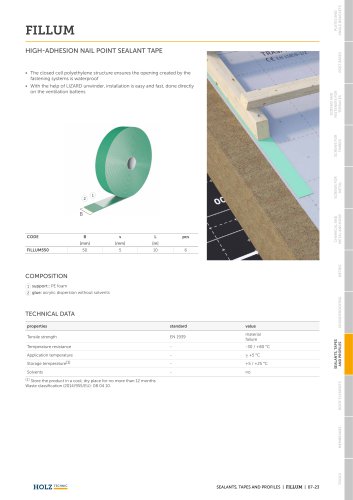

FILLUM

1 Pages

-

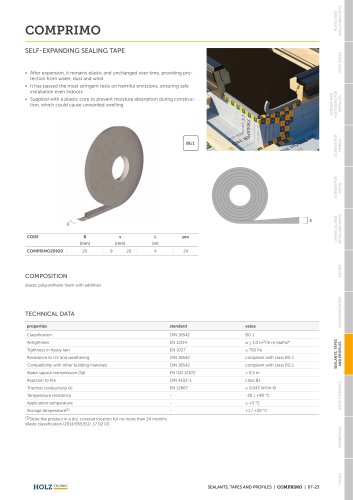

COMPRIMO

1 Pages