Catalog excerpts

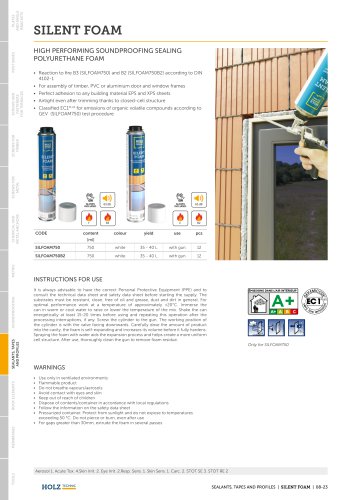

PLATES AND ANGLE BRACKETS POST BASES SILENT FOAM HIGH PERFORMING SOUNDPROOFING SEALING POLYURETHANE FOAM • Reaction to fire B3 (SILFOAM750) and B2 (SILFOAM750B2) according to DIN 4102-1 • Perfect adhesion to any building material EPS and XPS sheets • Airtight even after trimming thanks to closed-cell structure • Classified EC1PLUS for emissions of organic volatile compounds according to GEV (SILFOAM750) test procedure SCREWS AND FASTENERS FOR TERRACES • For assembly of timber, PVC or aluminium door and window frames GLOVES INCLUDED INSTRUCTIONS FOR USE It is always advisable to have the correct Personal Protective Equipment (PPE) and to consult the technical data sheet and safety data sheet before starting the supply. The substrates must be resistant, clean, free of oil and grease, dust and dirt in general. For optimal performance work at a temperature of approximately +20°C. Immerse the can in warm or cool water to raise or lower the temperature of the mix. Shake the can energetically at least 15-20 times before using and repeating this operation after the processing interruptions, if any. Screw the cylinder to the gun. The working position of the cylinder is with the valve facing downwards. Carefully dose the amount of product into the cavity, the foam is self-expanding and increases its volume before it fully hardens. Spraying the foam with water aids the expansion process and helps create a more uniform cell structure. After use, thoroughly clean the gun to remove foam residue. Only for SILFOAM750 Use only in ventilated environments Flammable product Do not breathe vapours/aerosols Avoid contact with eyes and skin Keep out of reach of children Dispose of contents/container in accordance with local regulations Follow the information on the safety data sheet Pressurized container. Protect from sunlight and do not expose to temperatures exceeding 50 °C. Do not pierce or burn, even after use • For gaps greater than 30mm, extrude the foam in several passes ROOF ELEMENTS SEALANTS, TAPES AND PROFILES CHEMICAL AND METAL ANCHORS GLOVES INCLUDED Aerosol 1. Acute Tox. 4.Skin Irrit. 2. Eye Irrit. 2.Resp. Sens. 1. Skin Sens. 1. Carc. 2. STOT SE 3. STOT RE 2

Open the catalog to page 1

PLATES AND ANGLE BRACKETS film formation time 23 °C / 50% RH time required for complete hardening 23 °C / 50% RH acoustic insulation of joints RS,w water vapour resistance factor (μ) water vapour transmission (Sd) thickness: 70 mm temperature resistance once hardened application temperature (spray can, support and environment) transport temperature storage temperature film formation time 23 °C / 50% RH(1) time required for complete hardening 23 °C / 50% RH(1) acoustic insulation of joints RS,w temperature resistance once hardened application temperature (spray can, support and environment)...

Open the catalog to page 2All HOLZ TECHNIC catalogs and technical brochures

-

TITAN F

9 Pages

-

TITAN N

17 Pages

-

TITAN PLATE C

8 Pages

-

TITAN PLATE T

4 Pages

-

UV-T

9 Pages

-

WHT PLATE T

4 Pages

-

XEPOX

14 Pages

-

FACADE BAND UV

2 Pages

-

WINDOW BAND

2 Pages

-

PROTECT

2 Pages

-

LEVEL BAND

1 Pages

-

BUTYL BAND

1 Pages

-

ALU BAND

1 Pages

-

AIR GLUE

2 Pages

-

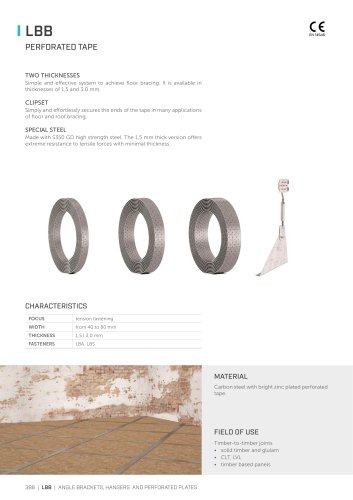

LBB

6 Pages

-

WHT PLATE C

8 Pages

-

GROUND BAND

4 Pages

-

FILLUM

1 Pages

-

COMPRIMO

1 Pages