Catalog excerpts

CONTROLS GUIDE APPLICATIONS I

Open the catalog to page 1

GRUNDFOS CONTROLS – INTRODUCTION FOREWORD Do you need controls? The demands for controls increase and are often requested on pumps, when it comes to optimum operation, high reliability and monitoring of data. Therefore, Grundfos has updated the Controls Guide, which gives in a simple manner an overview about applications and the related controls of speed controled pumps and pump systems. We have elaborated a Guide for engineers and technicians who work with design and installation of pumps and pump systems, containing answers to a wide range of controls for pumps. The handbook can either be...

Open the catalog to page 2

GRUNDFOS CONTROLS – CONTENT TABLE OF CONTENT System Application area Application area 8. Const. pressure & On/Off 21. Solar water solution Further information

Open the catalog to page 3

GRUNDFOS CONTROLS - H EATING 1. HEATINGMEDIUM/LARGE BUILDINGS Plan heating systems from the outside in Knowing the flows and temperatures required for radiators, under-floor heating, etc., lets you design your system based on known demands on central equipment. Our external controls and integrated frequency converters ensure maximum system intelligence, flexibility and the lowest costs. Think about the whole system In heating systems, energy efficient pumps are only half the story. With the right system design, you can minimise energy consumption, increase comfort levels and future-proof...

Open the catalog to page 4

GRUNDFOS CONTROLS - H EATING Boiler shunt pump The primary task of the boiler shunt pump is to ensure that the temperature differences between top and bottom of the boiler are not too big, big temperature differences cause tension in the material and thus reduce the life of the boiler. For certain types of fuel there is a risk of corrosion at too low temperatures at the bottom of the boiler. Maximum safety is ensured when using a controlled pump, and the energy saving is optimal. TPE: The pumps have an integrated frequency converter and motor protection. A temperature transmitter with an...

Open the catalog to page 5

GRUNDFOS CONTROLS - H EATING 1.4 HEAT SURFACES 1.5 HEAT RECOVERY The pump is set at uncontrolled, and the signal from the central control unit is connected to the analog entry (0-10V or 0/4-20 mA). Grundfos GO remote control must be used in connection with setting up the pump. Heat recovery The purpose of the system is to recover the heat of the outlet air. The primary task of the pump is to ensure an optimal flow between the heating surfaces. The pump/valve is controlled from the general control unit of the ventilation system. The saving potential of using a controlled pump in stead of...

Open the catalog to page 6

GRUNDFOS CONTROLS - H EATING District hot water circulation The purpose of the system is domestic hot water heating. The function of the circulator pump is to ensure that hot water is always available as close to the tapping point as possible, in order to reduce waste of water and increase the comfort. In certain installations (loading circuits) the pump can at the same time ensure the circulation between the inverter and the storage tank. Normally uncontrolled pumps are used, because usually the flow variation is only small. It may be advantageous to use controlled pumps for adjustment of...

Open the catalog to page 7

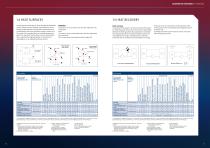

GRUNDFOS CONTROLS - DISTRICT HEATING 2. DISTRICT HEATINGCAMPUS/ LARGE SCALE DH 1 > Power plant 2 > Boiler houses 3 > Substation in distribution net 4 > Local substation with DHW production 5 > Local substation in the building 6 > Mixing loop in the building 2.1 MAIN PUMPS Main Pumps Due to variations in heating demand and flow, we recommend that the main pumps be speedregula ted and installed in parallel. Install a maximum of 3 pump s plus 1 as a standby. The use of speed-regulated pumps maximises the potential energy saving. It is important to check the efficiency at the duty point...

Open the catalog to page 8

GRUNDFOS CONTROLS - DISTRICT HEATING 2.2 BOOSTER PUMPS 2.3.DISTRIBUTED PUMPS In Instead of using a large closed pressure tank, one or more pumps together with an open storage tank will maintain constant static pressure in the system. If the system pressure exceeds the allowable level, a relief valve will lead the water back to the tank. It is recommended that treated water be used. The set point will be the static pressure of the system. It is recommendable always to install a standby pump. If the system is used for refilling the system please note that there is a risk of cavitation in the...

Open the catalog to page 9

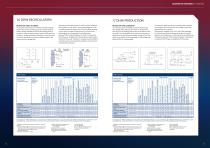

GRUNDFOS CONTROLS - DISTRICT HEATING TPE: The pumps have an integrated frequency converter and motor protection. A temperature transmitter with an output signal of 0/5-10V or 0/4-20 mA should be used. Grundfos GO remote control is used for start-up and later for extracting operating data. TP/NK: These pump types require an external frequency converter and an external regulator. 2.4 BOILER SHUNT PUMPS The primary task of the boiler shunt pump is to ensure that the temperature difference between the top and bottom of the boiler is kept low. Excessive temperature differences cause tension in...

Open the catalog to page 10

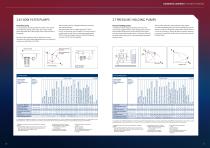

GRUNDFOS CONTROLS - DISTRICT HEATING 2.6 FLOW FILTER PUMPS 2.7 PRESSURE HOLDING PUMPS Flow filter pump It is necessary to continuously filter the water in the system to maintain the quality of the water. This is done using a partial flow filter with a flow of 10% of the maximum flow in the system. By measuring the pressure drop in relation to a known resistance and using a speed-regulated pump, it is possible to maintain constant flow in the filter. TPE:The pumps have an integrated frequency converter and motor protection. A Ap transmitter with an output signal of 0/5-10V or 0/4-20 mA...

Open the catalog to page 11

GRUNDFOS CONTROLS - DISTRICT HEATING Temperature shunt pumps TPE: The pumps have an integrated frequency converter and A temperature shunt must ensure a constant temperature motor protection. at the top of the heat exchanger to avoid tension on the A temperature transmitter with an output signal of 0/5-10V material and to minimize the risk of leakage. The correct or 0/4-20 mA should be used. Grundfos GO remote control is temperature depends on the heat exchanger. used for start-up and later for extracting operating data. TP/NK: These pump types require an external frequency...

Open the catalog to page 12All Grundfos catalogs and technical brochures

-

Product Brochure

6 Pages

-

Conex® DIA-G, DIS-G

2 Pages

-

COMFORT PM AUTOADAPT

2 Pages

-

CMBE BOOSTER

2 Pages

-

GRUNDFOS CMBE TWIN BOOSTER

2 Pages

-

GRUNDFOS CIM/CIU

3 Pages

-

BMS hs, BMS hp, BMST, BMSX

5 Pages

-

PURIFY YOUR BUSINESS

9 Pages

-

GRUNDFOS BACMON

16 Pages

-

ALPHA2, ALPHA2 L

19 Pages

-

ALPHA2 L, Model A

2 Pages

-

ALPHA1 L

2 Pages

-

ALPHA1

2 Pages

-

Grundfosliterature-5141099

8 Pages

-

Grundfosliterature-3223346

4 Pages

-

Grundfosliterature-3579569

8 Pages

-

Grundfosliterature-5616210

8 Pages

-

Grundfosliterature-5565188

7 Pages