Catalog excerpts

groeri™ STEAMER APPLICATIONS The purchase of a steamer is an important investment that needs to pay off. Whether it be a first time purchase to expand or improve a menu, or a piece to increase volume, we have the right steamer for your application. The below chart will assist in choosing the right Groen steamer for each application by pairing the product being steamed with the style of cooking. STEAMER DEFINITIONS boilerless, high performance ENERGY STAR® rated batch steamer that is also LEED compliant for less than 1.5 gallons of water use per hour. maintenance required with a boiler or generator unit while still delivering flexible and a la carte style cooking. steamer able to handle and dispose of the high fatty proteins of seafood when cooking at less the expense HYPLUS A boiler steamer able to power additional direct steam kettles for a single source power supply. Flexible for All Seafood Applications STYLE & TYPE DEFINITIONS BATCH Batch or production cooking is filling the steam cavity with product and allowing the cooking cycle to run its course without the introduction of new product in the cavity, (example: schools particularly K-12 need to produce large volumes of re-thermed food in a fast timeline as they are not cooking to order but serving in bulk a batch steamer VERSATILE Primarily batch cooking with the flexibility of a la carte cooking when required, (example: on occasion this full service restaurant receives orders for spaghetti, an item on their menu for which the noodles are cooked in the morning via batch style but are re-thermed per order a la carte style during the lunch and dinner times. Therefore, this restaurant requires a unit with the flexibility of operating efficiently in both batch and a la carte cooking.) A LA CARTE A la carte or cook to order is the ability to introduce new product in the steam cavity as required by order, (example: high end restaurants often prepare each dish as it's ordered and require a steamer that can be interrupted in its cooking cycle by placing additional product within the steam cavity with little to no recovery time.) RE-THERM Re-therm is the process of bringing refrigerated or frozen precooked product back to serving temperature. (example: an Italian restaurant prepares full pans of lasagna each night for service the next day. As orders come in, individual pieces are steamed to fill the order.) BOILERLESS Boilerless is producing steam without the use of a boiler or a typical steam generator by use of a water reservoir, eliminating the maintenance required of those units as well as reducing water use. STEAM GENERATOR A steam generator is typically a stainless steel box with independent heat source that produces steam under minimal pressure (.25lb or less) for a steam cavity, introduced as an alternate to the more expensive boiler units. BOILER A mild steel pressure vessel typically rated for 12- 15psi operated by gas or electric power and used to give steam on demand to a steam cavity. CONNECTIONLESS Connectionless steamers are units that require manual water fill and drain and do not require a water or drain connection.

Open the catalog to page 1All GROEN catalogs and technical brochures

-

OM-CC-E_C2-E

28 Pages

-

OPERATOR-MANUAL

28 Pages

-

ELECTRIC-MODEL-HY-3EEF

2 Pages

-

ELECTRIC-MODEL-SSB-3EEF

2 Pages

-

FLOOR-GAS-MODEL-AH1

2 Pages

-

BPM-15EC/EA/EC2T

2 Pages

-

BPM-30/40GC/GA/GC2T

2 Pages

-

BPP-30/40EC/EA/EC2T

2 Pages

-

Retail Foodservice

8 Pages

-

Product Guide

12 Pages

-

HyPerSteam - Model (2)HY-3E

2 Pages

-

Intek - Model XSG

3 Pages

-

Intek - Model XS

3 Pages

-

Intek - Model XS4

3 Pages

-

Cabinet Base - (2)CTDC3-20SM

2 Pages

-

Cabinet Base - (2)CTDC3-20SE

2 Pages

-

Floor Kettle - Model DEE-4

2 Pages

-

Floor Kettle - Model AHS

2 Pages

-

Floor Kettle - Model AH-1

2 Pages

-

Table-Top Kettle - Model TDB

2 Pages

-

CBE-10G

2 Pages

-

Floor Kettles model DHS

2 Pages

-

Water Treatment

2 Pages

-

Combo Ease Story

2 Pages

-

Combo Ease HCCC

1 Pages

-

Electric HyPerSteam

2 Pages

-

Gas HyPerSteam

2 Pages

-

Smart Steam 100

2 Pages

-

Steamer Brochure

12 Pages

-

Braising pan

2 Pages

-

Braising pan Brochure

4 Pages

-

Table Top kettles

1 Pages

-

Core products

2 Pages

Archived catalogs

-

KETTLE BROCHURE

8 Pages

-

COMBO EASE

8 Pages

-

CORE PRODUCTS

8 Pages

-

Vortex100

8 Pages

-

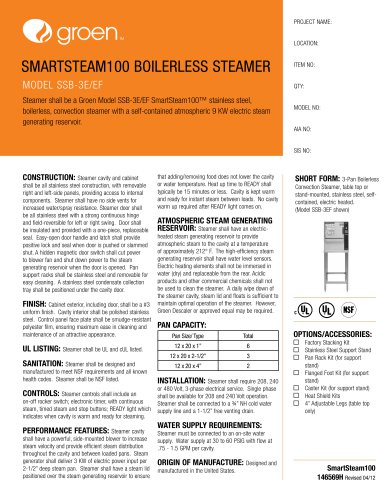

SmartSteam100 Boilerless Steamer

8 Pages

-

ECLIPSE BRAISING PANS

4 Pages