Catalog excerpts

• • IMPORTANT INFORMATION • • KEEP FOR OPERATOR • • IMPORTANT INFORMATION • • OPERATOR MANUAL MODELS: CC10-E, (2)CC10-E, C/2-20E, (2)C/2-20E CONVECTION COMBO™ Combination Steamer-Oven THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL. FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE . Information contained in this document is known to be current and accurate at the time of printing/creation. Unified Brands recommends referencing our product line websites, unifiedbrands.net, for the most updated product information and

Open the catalog to page 1

IMPORTANT — READ FIRST — IMPORTANT WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE CODES. SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT. DO NOT INSTALL THE UNIT IN ANY WAY WHICH WILL BLOCK THE RIGHT SIDE VENTS, OR WITHIN 12 INCHES OF A HEAT SOURCE SUCH AS A BRAISING PAN, DEEP FRYER, CHAR BROILER OR KETTLE. LEVEL THE UNIT FRONT TO BACK, OR PITCH IT SLIGHTLY TO THE REAR, TO AVOID DRAINAGE...

Open the catalog to page 2

Table of Contents OPERATOR WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 EQUIPMENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 INSPECTION AND UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 WATER QUALITY AND TREATMENT . . . . . . . . . . . . . . . . . ....

Open the catalog to page 3

OM-CC-E and C/2-E Equipment Description Your Groen Convection Combo™ has a stainless steel cooking chamber, an air heating compartment with electric heating elements and fan, a steam generator with electric heating elements, and a control compartment which houses other electrical components. 27. As a convection oven 28. As a self-contained, pressureless steamer 29. As a combination oven-steamer CC10-E and C/2-20E models differ in cooking chamber size and capacity: All major components of the Convection Combo™ are encased in a 16 gauge stainless steel cabinet. Glass fiber insulation, lines...

Open the catalog to page 4

OM-CC-E and C/2-E Inspection and Unpacking Your Convection Combo™ will be completely assembled in a heavy shipping carton or wooden crate, and attached to a skid. On receipt, inspect the carton or crate carefully for exterior damage. Write down the model number, serial number and installation date and keep this information for future reference. Space for these entries is provided at the top of the Service Log in the back of this manual. CAUTION SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT. CAUTION THIS UNIT IS VERY HEAVY. YOU SHOULD GET HELP AS NEEDED TO LIFT THIS WEIGHT...

Open the catalog to page 5

OM-CC-E and C/2-E Installation and Start-Up WARNING THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE CODES. CAUTION DO NOT INSTALL THE UNIT WITH THE RIGHT SIDE VENTS BLOCKED OR WITHIN 12 INCHES OF A HEAT SOURCE (SUCH AS A BRAISING PAN, DEEP FRYER, CHAR BROILER OR KETTLE). DO NOT INSTALL TO THE LEFT OF ANY OPEN-FLAME EQUIPMENT. DO NOT INSTALL WITHIN FOUR FEET OF A STEAM DRAIN. TO AVOID DRAINAGE PROBLEMS,...

Open the catalog to page 6

OM-CC-E and C/2-E should have separate protection for the upper and lower steamer-ovens. FOR CC10-E Models: The ground terminal is found on the relay bracket below the terminal block. The Convection Combo™ must have a separate ground wire for safe operation. The ground wire must be at least 10 AWG (2.6 mm). CURRENT DEMAND CC10-E MODELS Voltage FOR C/2-20E Models: The ground terminal is found below the terminal block. The Convection Combo™ must have a separate ground wire for safe operation. The ground wire must be at least 8 AWG (3.3 mm) for a 100 amp circuit breaker or 10 AWG (2.6 mm) for...

Open the catalog to page 7

OM-CC-E and C/2-E drain elbow with a clamp. Do not use plastic pipe. The drain must withstand boiling water. NOTE: Improper drain connection will void the warranty. b. CC10-E and C/2-20E With Drain Tank WARNING: DO NOT CONNECT THE DRAIN DIRECTLY TO A BUILDING DRAIN. CC10-E Models: A 1½ inch (4 cm) ID hose may be attached to the supplied drain elbow with a clamp. There must be a free air gap between the end of the hose and the building drain. The free air gap should be as close as possible to the unit’s drain. There must also be no other elbows or other restrictions between the unit drain...

Open the catalog to page 8

Proper Drain Line Connections

Open the catalog to page 9

OM-CC-E and C/2-E Initial Start-Up WARNING ANY POTENTIAL USER OF THE EQUIPMENT SHOULD BE TRAINED IN SAFE AND CORRECT OPERATING PROCEDURES. After the Convection Combo™ has been installed, test it to ensure that it is operating correctly. 1. Remove all literature and packing materials from the interior and exterior of the unit. 2. Check that the cold water supply line is open and that none of the fittings are leaking. 4. High Altitude Operation. At altitudes above 5,000 feet (1524m), the unit will not operate in the Steamer or Combo Modes unless the altitude is set. The Convection Combo™ is...

Open the catalog to page 10

OM-CC-E and C/2-E NOTE: The timer does not control the oven in either the Combo or Oven Modes. Examples: 2 minutes = 00:02 (Just press 2). 1 hour and 30 minutes = 01:30 (Press 1, 3, and 0, or press 9,0 the timer will change to 1:30) 9. To Test Oven Mode Operation, turn on the power and clear the Time/Status display. Press the OVEN touch pad. Set the cook temperature to 350oF (175oC). The WAIT light will come on. Within six minutes from a cold start, the WAIT light should go out and the READY light should come on. When that happens, turn the COOK temperature setting down to 320oF (160oC)....

Open the catalog to page 11All GROEN catalogs and technical brochures

-

OPERATOR-MANUAL

28 Pages

-

ELECTRIC-MODEL-HY-3EEF

2 Pages

-

ELECTRIC-MODEL-SSB-3EEF

2 Pages

-

FLOOR-GAS-MODEL-AH1

2 Pages

-

BPM-15EC/EA/EC2T

2 Pages

-

BPM-30/40GC/GA/GC2T

2 Pages

-

BPP-30/40EC/EA/EC2T

2 Pages

-

Retail Foodservice

8 Pages

-

Product Guide

12 Pages

-

HyPerSteam - Model (2)HY-3E

2 Pages

-

Intek - Model XSG

3 Pages

-

Intek - Model XS

3 Pages

-

Intek - Model XS4

3 Pages

-

Cabinet Base - (2)CTDC3-20SM

2 Pages

-

Cabinet Base - (2)CTDC3-20SE

2 Pages

-

Floor Kettle - Model DEE-4

2 Pages

-

Floor Kettle - Model AHS

2 Pages

-

Floor Kettle - Model AH-1

2 Pages

-

Table-Top Kettle - Model TDB

2 Pages

-

CBE-10G

2 Pages

-

Floor Kettles model DHS

2 Pages

-

Water Treatment

2 Pages

-

Combo Ease Story

2 Pages

-

Combo Ease HCCC

1 Pages

-

Electric HyPerSteam

2 Pages

-

Gas HyPerSteam

2 Pages

-

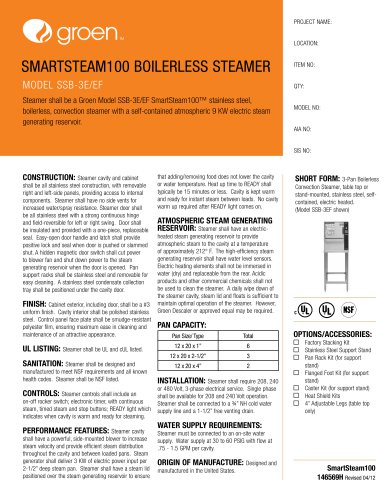

Smart Steam 100

2 Pages

-

Steamer applications

1 Pages

-

Steamer Brochure

12 Pages

-

Braising pan

2 Pages

-

Braising pan Brochure

4 Pages

-

Table Top kettles

1 Pages

-

Core products

2 Pages

Archived catalogs

-

KETTLE BROCHURE

8 Pages

-

COMBO EASE

8 Pages

-

CORE PRODUCTS

8 Pages

-

Vortex100

8 Pages

-

SmartSteam100 Boilerless Steamer

8 Pages

-

ECLIPSE BRAISING PANS

4 Pages