Catalog excerpts

TECHNICAL INFORMATION VRK 233 CONSTANT VOLUME FLOW CONTROLLER The volume flow controllers VRK are used in complex piping systems for automatically controlling the amount of air distribution. Their task is to maintain a predetermined desired value of the air flow for the supply or exhaust air of a room sustainable and independent from fluctuating channel air pressure. In constant-volume controllers without auxiliary power, the flow control is achieved by an easy-moving, asymmetrical angled control panel that ensures a sensitive response and control behavior even for small amounts of air flow rates. RESPONSE AND CONTROL ACCURACY The controller operates from the minimum pressure difference, which is a function of the volume flow (see diagram), up to the maximum pressure difference of 1000 Pa in a stable control range. Over this entire pressure range, the flow rate deviation is ± 10%. For smaller air speeds below 4 m/s, the flow deviation can be ± 20%. Unfavorable flow conditions, pollution or minor bracing during installation can also cause larger deviations. TEMPERATURE RANGE The control panel is mounted in a smooth and maintenancefree PTFE bushing. The support is not guided through the pipe bodyshell, which means that no leaks or high-frequency whistling sounds occur. A pneumatic piston damper prevents overshoot and oscillation of the control plate and ensures an accurate response and control behavior. The exact balancing of the control plate is ensured by a counterweight arranged vertically on the control plate, which ensures an accurate control response in all orientations. The flow profile in front of the flow controller should be crosssection-filling, since unfavorable flow conditions (such as asymmetric flow, necking, deflection around sharp edges) can negatively affect the response and control behavior. Constant volume flow controller, model VRK - circular, self-regulating with rubber seal air tight Class D laser-welded housing. The components of the controller are largely resistant to aging and temperature resistant from -30°C to +100 °C. As for volume controllers with actuators the limiting operating temperatures of the actuators apply, -30°C to +50°C. CONTROLLER ASSEMBLY The constant-volume flow controllers are shipped with a reference flow rate set at the factory. The volume flow can be changed at any time by the customer and read on a scale by manual adjustment with an Allen wrench (2 mm). Optionally, the air flow setpoint can be varied by an electric actuator. CONSTANT VOLUME FLOW CONTROLLER VRK - P1 Catalogue, specifications subject to change ©

Open the catalog to page 1

TECHNICAL INFORMATION TECHNICAL INFORMATION INSULATION According to DIN EN 12097 an accessibility to the piping system and the volume flow controller for operation and maintenance must be observed. When installing behind redirections or junctions, the free flow section must be at least 2,5 * ND. PIPE BODY CONSTANT VOLUME FLOW CONTROLLER The flow controllers can be implemented with a sound and heat insulation of 50mm thickness. INSTALLATION NOTE The body tubes are made of galvanized sheet steel. These are laser butt welded without disturbing misalignment of the inner and outer shell surface....

Open the catalog to page 2

VRK 233 CONSTANT VOLUME FLOW CONTROLLER • Constant volume flow controller with proof plug connection (only fitting measure) • Automatically regulating without auxiliary energy • Customers can change the amount of air by manual adjustment l1 = Insertion length total length = l1 + 2 * l2 = l3 Controller structure and functioning as before, factory default setting, two-setpoint control via electric adjustment for an operating voltage of 24 volts, 50 Hz, as a two-setpoint controller with no intermediate position, Vmin and Vmax can be fixed by adjusting the mechanical travel stops. Actuator...

Open the catalog to page 3

VRK 233 CONSTANT VOLUME FLOW CONTROLLER NOMINAL DIAMETER FLOW VELOCITY VOLUME FLOW MINIMUM STATIC PRESSURE DIFFERENCE [Pa]: ∆P [Pa] ACCORDING TO DIAGRAM FLOW CONTROLLER MINIMUM RESPONSE PRESSURE DIFFERENCE When dimensioning the tube system, the static minimum response pressure difference of the flow regulator according to this diagram is to be observed. DIMENSIONS - WORKING RANGE SIZE CONSTANT VOLUME FLOW CONTROLLER VRK - P4 Catalogue, specifications subject to change ©20

Open the catalog to page 4

VRK 233 CONSTANT VOLUME FLOW CONTROLLER AIR FLOW NOISE GENERATED BY THE CONTROLLER Wird in einen Raum eingeblasen, tritt durch die Rohrmündungsöffnung und durch die Raumdämpfung eine zusätzliche Dämpfung und damit eine Reduzierung des Schalleistungspegels ein. Gemäß VDI 2081 lassen sich die Raum- und Mündungsdämpfung berechnen. Überschlägig können hierfür ca. 8 dB in If air is gebracht werden. the tube orifice and the room absorption provide an additional damping and thus reduce the sound power Abzug blown into a room, level. According to VDI 2081, the spatial and mouth damping can be...

Open the catalog to page 5

VRK 233 CONSTANT VOLUME FLOW CONTROLLER S: single walled, non-insulated D: double walled, insulated with 50mm mineral wool 1: without power supply 5: with servomotor 24V CONSTANT VOLUME FLOW CONTROLLER VRK - P6 Catalogue, specifications subject to change ©2020

Open the catalog to page 6All GRADA International catalogs and technical brochures

-

SLS_2024

11 Pages

-

MCAS

5 Pages

-

CS400_2022

4 Pages

-

WR230

5 Pages

-

RDR

8 Pages

-

RLV Brochure

11 Pages

-

WP100P

3 Pages

-

DP100S • DP100T

2 Pages

-

A-170 • G-170

3 Pages

-

G-100

3 Pages

-

SLS

6 Pages

-

A780

3 Pages

-

BB

13 Pages

-

SPB

2 Pages

-

GK250

2 Pages

-

WGC

1 Pages

-

DA350

3 Pages

-

SPP

2 Pages

-

SPS

2 Pages

-

SLB

2 Pages

-

SLF

3 Pages

-

VF750

2 Pages

-

GT007

2 Pages

-

URSIL

1 Pages

-

KA

2 Pages

-

RVC

2 Pages

-

BR

13 Pages

-

BS

19 Pages

-

SP900

1 Pages

-

SP800

2 Pages

-

SP700

1 Pages

-

LP400

4 Pages

-

LP300

4 Pages

-

DP100

2 Pages

-

DP150

2 Pages

-

DP100P

6 Pages

-

SP100

2 Pages

-

K6

26 Pages

-

WBP

2 Pages

-

WO331

2 Pages

-

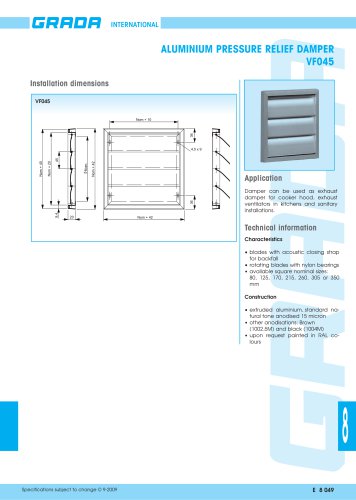

VF045

2 Pages

-

WB900

2 Pages

-

W-801

2 Pages

-

W331

2 Pages

-

JD Short pipe

4 Pages

-

JD Long Pipe

4 Pages

-

VT061

2 Pages

-

RLV

12 Pages

-

AG300

2 Pages

-

AV500

2 Pages

-

Z600

4 Pages

-

VM

2 Pages

-

AK700

7 Pages

-

WR210

3 Pages

-

WS210

3 Pages

-

WS200

4 Pages

-

WS400

3 Pages

-

WR400

2 Pages

-

WR200

2 Pages

-

WR250

2 Pages

-

WT100

4 Pages

-

WS360

2 Pages

-

WT500

3 Pages

-

WR300

2 Pages

-

SE700

2 Pages

-

SE900

2 Pages

-

SE800

2 Pages

-

RT151

4 Pages

-

TE600

4 Pages

-

LT360

12 Pages

-

LT350

12 Pages

-

AS100

4 Pages

-

AH700

3 Pages

-

CB780

2 Pages

-

FH100

4 Pages

-

CB400

2 Pages

-

A250

2 Pages

-

A980

2 Pages

-

GK150

2 Pages

-

A600

9 Pages

-

GP360

2 Pages

-

A710

4 Pages

-

False ceiling

6 Pages

-

EE200

2 Pages

-

EE300

2 Pages

-

EE400

2 Pages

-

DC570

2 Pages

-

DC560

2 Pages

-

DR160

2 Pages

-

EG400

2 Pages

-

TE370

2 Pages

-

CC600

2 Pages

-

CE100

2 Pages

-

DA370

2 Pages

-

DA360

2 Pages

-

DG60

6 Pages

-

TS600

4 Pages

-

TS750

2 Pages

-

DG360

3 Pages

-

MCAS

3 Pages

-

CS400

21 Pages

-

WGR-WGS_PI

2 Pages

-

MSS

8 Pages

-

A100-G100_PI

4 Pages

-

FALSE CEILING DIFFUSERS

6 Pages

-

CS500

2 Pages

-

Z-600

2 Pages

Archived catalogs

-

Select & Go

41 Pages

-

K-30

6 Pages

-

G-801

2 Pages

-

SE600

2 Pages

-

WT100S

2 Pages

-

CE100 / DE100

2 Pages

-

A-100 / G-100

4 Pages