Website:

GLAMOX

Website:

GLAMOX

Group: Glamox Group

Catalog excerpts

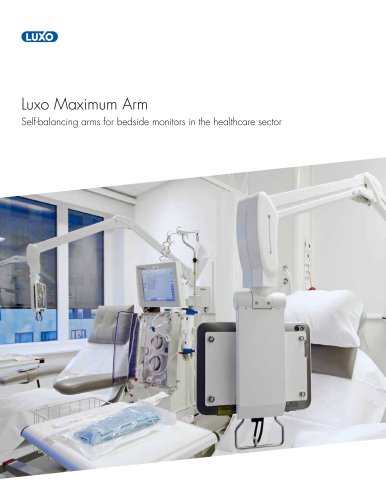

Luxo Maximum Arm Self-balancing arms for bedside monitors in the healthcare sector

Open the catalog to page 1

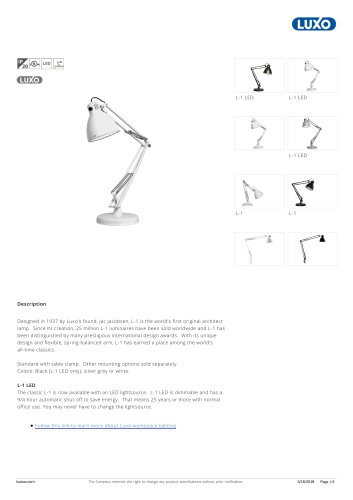

A history of caring for the ealthcare sector h For more than 80 years Luxo has designed innovative, ergonomic lighting products and concepts. Luxo products improve lighting conditions, taking particular care of individual needs. Our history of lighting for the individual began with the development of the Luxo L-1 task light in 1937 The freedom of movement and the ability to place the light . exactly where it was needed forever changed our working environments. L-1 was designed by Luxo’s founder, the industrialist Jac Jacobsen, and is still in production. The lamp arm is balanced by...

Open the catalog to page 3

Perfect balance Maximum strength The Maximum arm has been developed specifically for use with monitors, tablets and patient terminals. It offers long reach, perfect balance, and maximum vertical and horizontal movement. It is easily repositioned as required. The wiring is built into the arm, allowing cabling with connectors to be used without modification. The Maximum arm is made to order. The springs require careful calibration to match the weight of what it is meant to carry. Correctly calibrated, the self-balancing arm with internal gas springs will last for more than 50,000 cycles of...

Open the catalog to page 5

Maximum 150 Load capacity: 1-7 kg The Maximum 150 arm has been developed specifically for use with monitors and patient terminals. It offers a 150 cm reach, very high vertical movement, perfect balance, and is easily and quickly repositioned as required. Wiring is built into the arm, allowing cabling with connectors to be used without modification.

Open the catalog to page 6

Technical information The arm is designed to fully protect the internal wiring. It is designed to allow for 5 cm bending radius, minimizing stress and potential cable breakage. Wiring is built into the arm, not pulled through. The advantage is that cabling with large connectors such as HDMI can be used without modification. The Maximum arm is built to order. This is a self-balancing arm with internal gas springs. The gas springs need careful calibration to give optimum performance. Correctly calibrated, the arm will last for more than 50,000 cycles. Arm family: Maximum arm Arm type: Closed...

Open the catalog to page 7

Maximum 110 Load capacity: 1-10 kg The Maximum 110 arm has been developed specifically for use with monitors and patient terminals. It offers a 110 cm reach, very high vertical movement, perfect balance, and is easily and quickly repositioned as required. It is more compact than the Maximum 150, and can carry weights of up to 10 kg. Wiring is built into the arm, allowing cabling with connectors to be used without modification.

Open the catalog to page 8

Technical information The arm is designed to fully protect the internal wiring. It is designed to allow for 5 cm bending radius, minimizing stress and potential cable breakage. Wiring is built into the arm, not pulled through. The advantage is that cabling with large connectors such as HDMI can be used without modification. The Maximum arm is built to order. This is a self-balancing arm with internal gas springs. The gas springs need careful calibration to give optimum performance. Correctly calibrated, the arm will last for more than 50,000 cycles. Arm family: Maximum arm Arm type: Closed...

Open the catalog to page 9

Product options Colors VESA mount Secure VESA mount for monitor or digital device mounting. It is designed to the VESA 75 standard, a 7 cm by 7 cm .5 .5 hole pattern, and can carry a total weight up to 7 kg. The screen mount has built-in springs to ease the movement of the screen.

Open the catalog to page 10

Grab handle Accessory Grab handle for VESA mount allows for easy adjustability of the screen. The handle can be fitted to the reverse side of the screen permitting easy adjustability. Spigot options Male spigot The inner diameter is 20 mm. The outer diameter (through bracket) is 25 mm. The cables and connectors must fit in a hole with a maximum diameter of 20 mm. Exit through spigot Female spigot The inner diameter is 18 mm. The inner diameter towards the bracket is 32 mm. The cables and connectors must fit in a hole with a maximum diameter of 18 mm. Exit throught bottom joint Cable passage...

Open the catalog to page 11

Product options Arm movement restriction stopper Top position 81.5 cm Stop #1 = 61.5 cm (the arm is restricted from closing by 20 cm) Stop #2 = 41.5 cm (the arm is restricted from closing by 40 cm) In some applications the arm movement needs to be restricted to avoid collisions with the ceiling, wall mounted equipment, ventilation, etc. This is achieved by using a restriction stopper in the arm which keeps the front and back arms from folding onto each other when in a resting position. The further down the arm the stopper is inserted, the more open it will be. (Measurements based on Maximum...

Open the catalog to page 12

Company name: Street address: Phone Contact person City/State/Zip Email address: Available product options Reach length of arm Standard color VESA 75 mount Heat sink Grab Handle Spigot Cable passage Warranty Stopper Wall mount Pack quantities Screen specification Terminal type: Width : cm Phone Smart card reader Headset Keyboard Other 1 Other 2 Cables I I 150 cm □ White RAL 9010 I | Yes □ No (standard) I I Yes □ Male (standard) □ Inside spigot (standard) 5 years □ No stopper □ Stopper position 2 (415 mm) □ Luxo wall bracket □ Maximum wall bracket I I Bulk packing (standard), 15 units...

Open the catalog to page 13

Quality assurance and testing Trust is good. Testing is even better. Because of the high demands on the quality and service life of the Maximum arm, we pay great attention to quality issues and testing. Testing: 30,000 cycles during six weeks All Luxo arms are tested at our own research and testing facilities. We run the Maximum arm (with cables) through cycle tests of 30,000 movements by robot. Each cycle lasts 2 minutes and involves all possible movements of the arm. The procedure takes a total of six weeks of continuous movement – day and night. 14

Open the catalog to page 14

ISO certification The Maximum arm is manufactured in accordance with the ISO 9001 quality standard. The factory also holds the ISO 14001 environmental approval and the ISO 13485 (medical) certificate. Our environmental routines are integrated in our quality systems.

Open the catalog to page 15All GLAMOX catalogs and technical brochures

-

group-ARIS-S

4 Pages

-

GSX_C70_familiebrosjyre_-17

16 Pages

-

C25-R

3 Pages

-

S80 DALI

3 Pages

-

C75-P

3 Pages

-

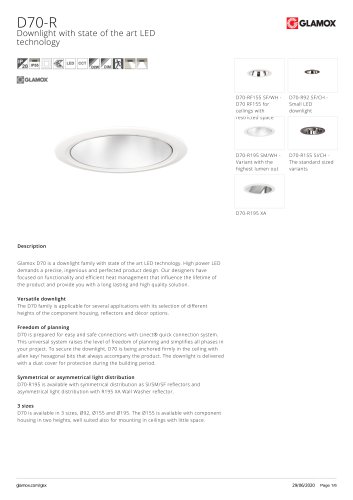

D70-R

6 Pages

-

i75

3 Pages

-

Welcome to our world of light!

149 Pages

-

Workspace Lighting Catalog

20 Pages

-

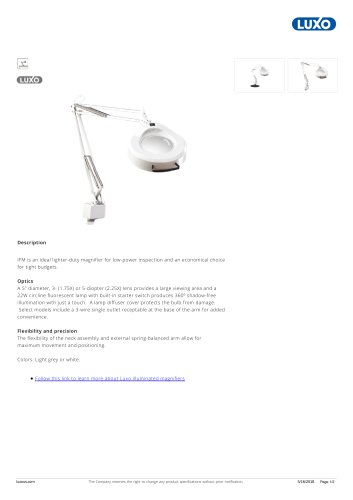

IFM

2 Pages

-

LFM-LED-G2

4 Pages

-

L-1

3 Pages

-

Luxo Quality Brochure

24 Pages

-

Industrial Products Brochure

20 Pages

-

Maximum

9 Pages

-

Low vision handout

4 Pages

-

Trace

4 Pages

-

Luxo Task Brochure 2016

28 Pages

-

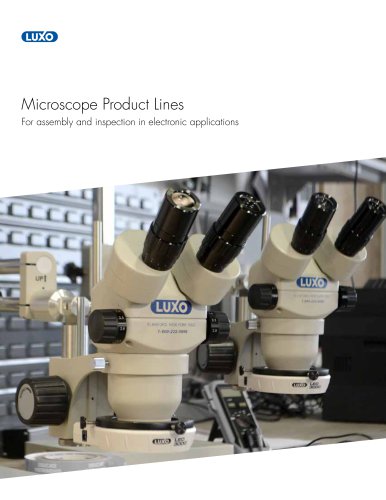

Luxo Microscope Product Lines

12 Pages

-

Trace

6 Pages

-

MLS

1 Pages

-

Perfect balance

28 Pages

-

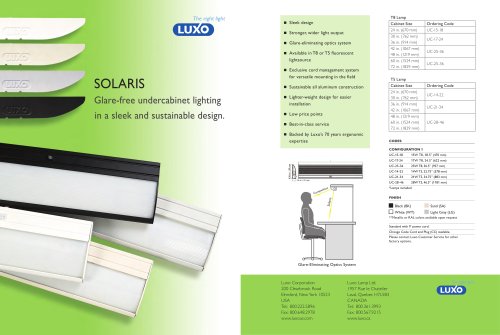

Solaris

2 Pages

Archived catalogs

-

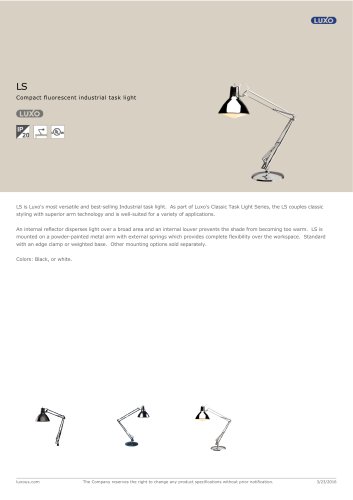

2018 LS

2 Pages

-

Luxo History Brochure

2 Pages

-

2016 LS

2 Pages

-

2014 Task

28 Pages

-

2014 Luxo Magnification

16 Pages

-

Lighting for Healthcare Brochure

12 Pages

-

Ninety Brochure

16 Pages

-

Luxo Task Brochure

34 Pages

-

L1 70 years

20 Pages

-

Catalogue 2006

308 Pages