Website:

Glamox AS

Website:

Glamox AS

Group: Glamox Group

Catalog excerpts

Dedicated to quality About quality assurance, test procedures and product certification

Open the catalog to page 1

Luxo is dedicated to quality Luxo, as part of the Glamox Group, is a leading supplier of lighting solutions and magnification products. We take pride in providing products of superior technical quality that work reliably under demanding conditions. Technology and expertise Our products and solutions are developed and tested by our engineers at our own research and testing facilities, and manufactured and certified in accordance with all relevant quality and environmental standards. They are based on the latest technology and expertise – and generations of experience. Our quality systems The...

Open the catalog to page 2

The UL/cUL mark designates our products as having met the requirements outlined by the National Electric code. Such products bearing the mark have been tested and approved by the Underwriters Laboratory and Underwriters Laboratory of Canada. The CE mark is a mandatory conformity marking for products sold in the European Economic Area (EEA). It is the manufacturer’s declaration that the product meets the requirements of the applicable EC directives. ENEC is the high quality European mark for electrical products that demonstrates compliance with European safety standards. The two-digit number...

Open the catalog to page 3

Contents Free fall shock tests Vibration testing Impact resistance Climatic testing IP rating (water) IP rating (objects) EMC testing UV radiation testing Photometry Spectrometry Salt mist spray test Sports hall ball tests Component testing Heat measurements Light data simulation Heat simulation Mechanical arm tests Production testing Modern testing facilities As a result of the high demands placed on the quality and durability of our products, the Glamox Group operates modern assessment and testing laboratories in Norway and Germany for the simulation of a wide variety of environmental...

Open the catalog to page 4

The luminaires in Bremen and Molde have been certified in accordance to the requirements of ISO 9001, ATEX and IECEx. The importance of testing and simulations The simulations performed in our laboratories aim to test our products in the most realistic conditions possible. In our environmental test centers, sample specimens of our luminaires undergo rough treatment indeed: They are dropped from a great height in shock tower tests, shaken vigorously by vibration testing equipment, soaked in water and dust, allowed to corrode in salt mist spray chambers and steamed in our climate testing...

Open the catalog to page 5

Free fall shock tests Mechanical shock has the potential for damaging a product. For this reason there are shock resistance requirements based on a number of international standards, depending on a luminaire’s intended application and purpose. We test our luminaires in accordance with these requirements for type approval purposes. Sometimes a shock may result in only minor damage which may not be critical for use. However, cumulative minor damage from several shocks could eventually result in the product becoming unusable, or cause the service life of the product to be shortened. Therefore...

Open the catalog to page 6

Vibration testing Many luminaires need to be tested for resistance to vibration. We have equipment to do pre-qualifying tests for vibration. Within the scope of vibration testing, three different types of tests are performed: Sinusodial vibration, various shock tests and random testing. Vibration testing Our equipment is designed for vertical, horizontal and lateral vibration testing. A slip table with an oil film is used to test products from impact with sinus, random and shock impulses. Acceleration sensors are used to investigate the behaviour of the test subject under the influence of...

Open the catalog to page 7

Impact resistance in sub-zero environments In mechanics, an impact is a high force or shock applied over a short time period when two or more bodies collide. Impact tests are used in studying the toughness of material. A material’s toughness is a factor of its ability to absorb energy during deformation. Brittle materials have low toughness as a result of the small amount of deformation that they can endure. The impact value of a material can also change with temperature. Generally, at lower temperatures the impact energy of a material is decreased. Minus 50°C We test our luminaires with...

Open the catalog to page 8

Climatic testing Environmental simulations in climate test chambers allow us to measure the effects of temperature and humidity on our products in a controlled manner. Climatic testing is required to ensure that our luminaires will perform to standard under the climatic conditions they will encounter in service use. Materials can deteriorate over time, ageing prematurely due to either high or low temperature extremes, while humid conditions may lead to condensation which can be damaging to electronic components. Our climate test chambers have a test space of up to 1,500 liters. They are...

Open the catalog to page 9

Submersion into water The luminaires are tested against ingress of water in up to 1 meter depth. IP rating (water) In our wetrooms we assess the protection of our luminaires against ingress of water, varying over differing degrees of protection, depending upon the requirements for the different types of lighting product. Water pressure tank The luminaires are submerged into a water pressure tank, simulating various depths beyond one meter. Spray water/splash water The luminaires are hosed with varying degrees of power, from fine spray to hard water jets. From rain testing through spray...

Open the catalog to page 10

IP rating (objects) In our laboratories and dust chambers we assess the protection of our luminaires against ingress of solid particles, varying over differing degrees of protection, depending upon the requirements for the different types of lighting product. Solid objects protection There are six levels of protection against the ingress of solid foreign objects, represented by the first digit in the two-digit IP rating of a product. > 50mm: Any large surface of the body, such as the back of a hand, but no protection against deliberate contact with a body part 12.5mm: Fingers or similar...

Open the catalog to page 11All Glamox AS catalogs and technical brochures

-

group-ARIS-S

4 Pages

-

GSX_C70_familiebrosjyre_-17

16 Pages

-

C25-R

3 Pages

-

S80 DALI

3 Pages

-

C75-P

3 Pages

-

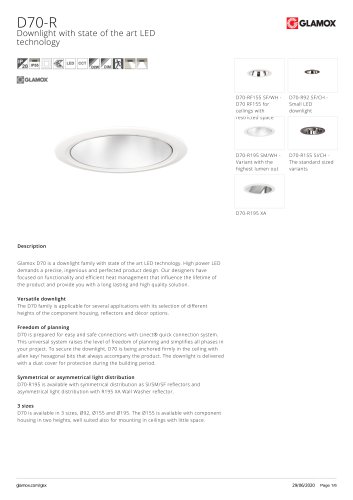

D70-R

6 Pages

-

i75

3 Pages

-

Welcome to our world of light!

149 Pages

-

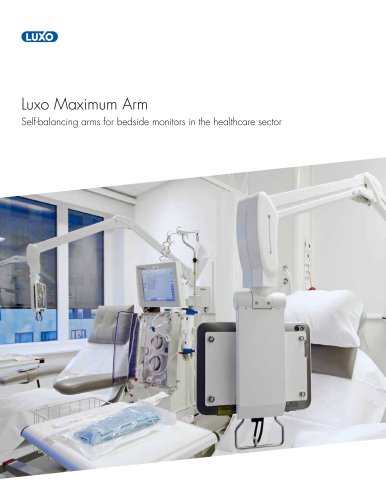

Luxo Maximum Arm

16 Pages

-

Workspace Lighting Catalog

20 Pages

-

LS

2 Pages

-

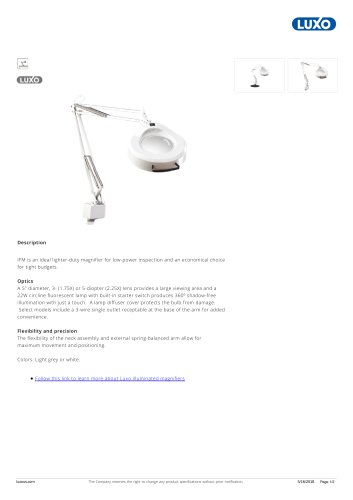

IFM

2 Pages

-

LFM-LED-G2

4 Pages

-

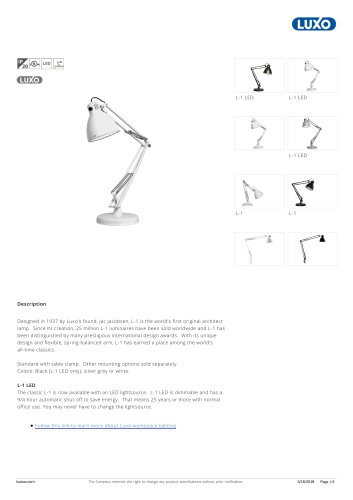

L-1

3 Pages

-

Industrial Products Brochure

20 Pages

-

Maximum

9 Pages

-

Low vision handout

4 Pages

-

Trace

4 Pages

-

Luxo Task Brochure 2016

28 Pages

-

Luxo Microscope Product Lines

12 Pages

-

Trace

6 Pages

-

MLS

1 Pages

-

Perfect balance

28 Pages

-

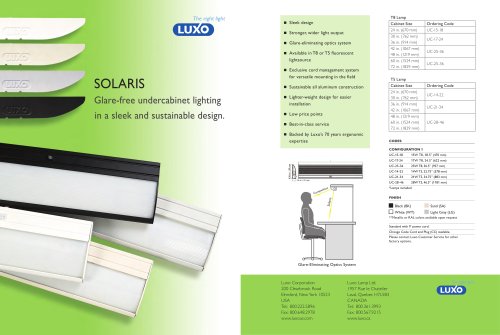

Solaris

2 Pages

Archived catalogs

-

Luxo History Brochure

2 Pages

-

LS

2 Pages

-

2014 Task

28 Pages

-

2014 Luxo Magnification

16 Pages

-

Lighting for Healthcare Brochure

12 Pages

-

Ninety Brochure

16 Pages

-

Luxo Task Brochure

34 Pages

-

L1 70 years

20 Pages

-

Catalogue 2006

308 Pages