Catalog excerpts

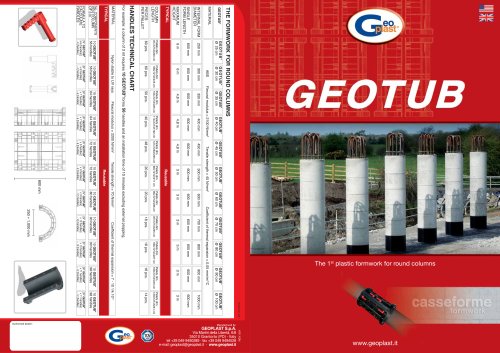

geotub reusable system in ABS • REUSABLE • LIGHT • MODULAR

Open the catalog to page 1

CONSTRUCTION and RESPECT: This is the vision which characterizes the work of Geoplast. To build buildings respecting the environment. Beginning from the choice of the raw materials. Our plastic formwork perfectly embodies this principle. THE ANNUAL WORLD CONSUMPTION OF WOOD IS EQUAL TO 1,5 BILLION M3, OF WHICH 55% IS USED IN CONSTRUCTION After having exhausted the resources of timber in Southeast Asia and Central Africa, logging is causing the deforestation of the Amazon Rainforest, which is considered the green lungs of our Planet. In the last three decades 55 million hectares of...

Open the catalog to page 2

THE FIRST FORMWORK IN ABS GEOTUB is the First Formwork in technopolymer for the construction of round and oval columns; it is a complete system For the production of columns, both for residential and industrial use. Extremely light and modular, GEOTUB is a new idea of reusable formwork, easy to store and cleanable just with water. Why ABS (Acrylonitrile Butadiene Styrene) High mechanical strength Shock resistance Thermal stability (-30°C / + 70°C; -22°F / + 158°F) Very high surface quality Recyclable material

Open the catalog to page 3

The only light, reusable and modular system for the production of round and oval columns light Weighting max 10 kg, GEOTUB can be handled quickly on site without having to use cranes or other mechanical lifting devices Light and easy to assemble, it can be installed and handled by a single person All elements are 600 mm long and only the elements necessary for the pour are used reusable GEOTUB is cost effective as it can be reused more than 100 times when properly used and mantained Concrete dos not stick to plastic: dismantling is extremely easy, the forms can be cleansed using just a...

Open the catalog to page 4

GEOTUB | THE MAIN PANEL Up to 80 kN/m2 fresh concrete pressure max REUSABLE GEOTUB MATERIAL Acrylonitrile Butadiene Styrene Coefficient of thermal expansion SIZE Minimum diameter Maximum diameter The handle The standard fixing item for all Geoplast Formwork Light and intuitive Firmly locks with a simple 90 degree turn Strength (guaranteed by specially engineered materials) HANDLE MATERIAL: POLYAMIDE - COEFFICIENT OF THERMAL EXPANSION 7-10 (1/K 10-5) www.geoplast.it

Open the catalog to page 5

actual size (mm) material weight (kg) package size (mm) No. pieces per pallet No. handles actual size (mm) material weight (kg) package size (mm) No. pieces per pallet No. handles

Open the catalog to page 6

actual size (mm) material weight (kg) package size (mm) No. pieces per pallet No. handles actual size (mm) material weight (kg) package size (mm) No. pieces per pallet No. handles

Open the catalog to page 7

Handle locking GEOTUB HANDLE

Open the catalog to page 8

GEOTUB | TECHNICAL DETAILS GEOTUB POUR HEIGHTS GEOTUB configuration of a column o o o o o 0 Nominal Length of Forms per No. handles Column diameter single form column of 3 mt per column of Length Max. pour height (single pour)

Open the catalog to page 9

REUSABLE COLUMNS All-round advantages GEOTUB is the first reusable plastic formwork for the construction of round columns. It allows a fast and easy dismantling without using releasing agents. The panels are very light: they can be handled and installed by a single person. Properly assembled and dismantled, and cleaned just with water, the product can be reused more than 100 times. Reusable Easier handling Smooth surface

Open the catalog to page 10

MARINE SOLUTIONS Water resistant As for all Geoplast formwork, GEOTUB is particularly suited to build columns when working in presence of water, which can make the work difficult and complicated. In this case the use of GEOTUB is the only possible solution, since it is made of ABS: in fact this material, compared to cardboard and steel, does not suffer from degradation due to natural weathering. Moreover, thanks to its lightness and modularity, the work of the laborers is much easier even in difficult situations such as those mentioned above. Easy to handle Does not suffer weathering...

Open the catalog to page 12

SEISMIC HAZARD ADJUSTMENT Extension of cross section The size of the columns should be adjusted, extending their cross section, to prevent the hazard of earthquakes. GEOTUB modular formwork are easy to handle manually and they allow to work even in narrow spaces, where steel formwork, too heavy and non-dismantlable, can not be used. Moreover, the handles allow a lateral installation, thus avoiding to insert the formwork from the top, as with cardboard ones. Easy to assemble Light panels Easy to handle

Open the catalog to page 13

RENOVATION OF DETERIORATED COLUMNS Protection of exposed reinforcement In the case of deteriorated concrete and exposed rebar it is necessary to repair the columns restoring an adequate concrete cover. GEOTUB formwork system is ideally suited for this kind of repair job as it is installed around the existing columns (unlike carboard tubes which are hindered by the presence of any structure above the columns). Its lightweight makes it much easier to use than heavy metal forms. Quick to assemble Simple to manage Reusable 100 times

Open the catalog to page 14

OVAL COLUMNS The ideal solution for car parks Most of the GEOPLAST formwork panels share the same module, so different systems are compatible with one another. GEOPANEL and the GEOTUB circular column formwork work together very efficiently to produce el- liptic columns. This is a very useful tool for the production of elliptic columns in multi-storey car-parks, much appreciated for their slender looks and the better maneuvering space given to vehicles.

Open the catalog to page 15

PRECAST COLUMNS Serial production of columns GEOTUB system is highly competitive not just for the construction of in-situ poured columns, but also for the creation of precast columns which can be assembled later. ABS formwork are ideal for the mass production of serial columns as it is very strong and it produce a very smooth concrete finish. Additionally it can be reused over than 100 times. Extreme strength Easy to handle inside industrial buildings No dismantling agent required

Open the catalog to page 16

ELECTRICAL GRID PYLONS FOUNDATIONS Foundations for electricity pylons GEOTUB is particularly suited for the construction of new foundations for electricity pylons: this kind of construction site consists of relatively small jobs, often in remote or scarcely accessible locations. The low weight and ease of use make it very simple to han- dle and transport the GEOTUB forms, reducing the production cycle time and improving safety. GEOTUB elements are easily assembled around existing foundations, greatly simplifying rebuilding or reinforcing jobs. Low weight Modular Reusable 100 times

Open the catalog to page 17All GEOPLAST catalogs and technical brochures

-

Geohouse System

20 Pages

-

Formwork Solutions

72 Pages

-

Foundation Solutions

84 Pages

-

Geoplast Catalogue 2022

124 Pages

-

Matrix

8 Pages

-

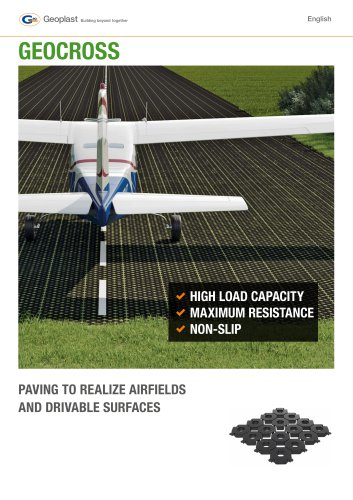

GEOCROSS

10 Pages

-

AQUABOX

26 Pages

-

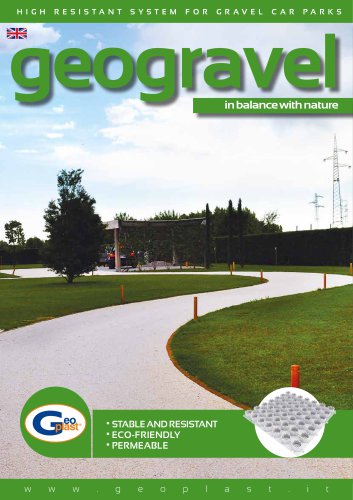

Geogravel

12 Pages

-

Airplast

12 Pages

-

Modulo

32 Pages

-

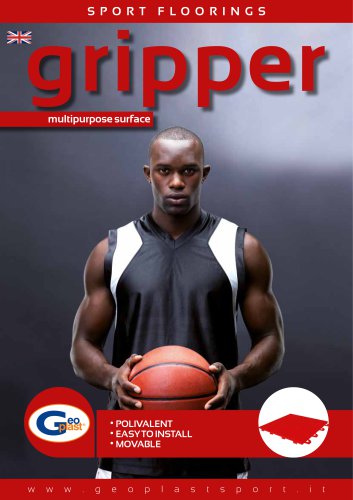

Gripper

16 Pages

-

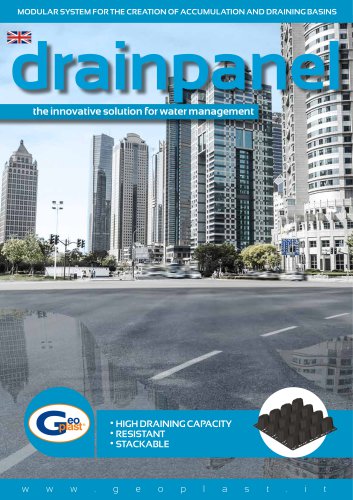

Drainpanel

12 Pages

-

Runfloor

8 Pages

-

Wall-y

8 Pages

-

Geoflor

2 Pages

-

Drening reflue

8 Pages

-

Drening

8 Pages

-

Skydome

8 Pages

-

Skyrail

8 Pages

-

Geopanel Art

2 Pages

-

Geotub

2 Pages

-

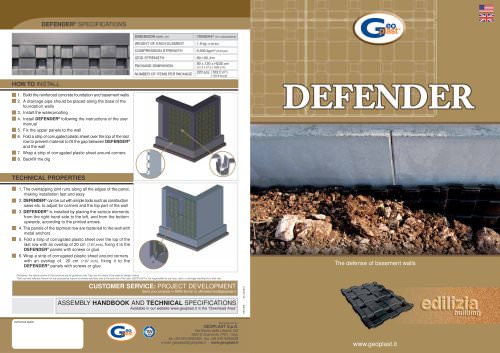

DEFENDER

2 Pages

-

MODULO FREEZE

8 Pages

Archived catalogs

-

MODULO

10 Pages