Website:

Forbo Flooring Systems

Website:

Forbo Flooring Systems

Group: Forbo

Catalog excerpts

Environmental Product DECLARATiON Marmoleum Tile 2.0 and 2.5MM FORBO FLOORING SYSTEMS RESILIENT LINOLEUM FLOOR COVERING Color t2874 "Coffee" - t2j6j "Rust" -12707 "Barley" ffedbo FLOORING SYSTEMS Marmoleum the most globally used brand of linoleum has been manufactured by Forbo for more than 150 years. Marmoleum is produced having low environmental impacts as a result of the combination of natural renewable materials and high recycle content. Forbo was the first flooring manufacturer to publish a complete Life Cycle Assessment (LCA) report verified by CML in 2000.In addition Forbo is now to publish Environmental Product Declarations (EPD) for all products including full LCA reports. This EPD is using all recognized flooring Product Category Rules and is including additional information to show the impacts on human health and eco-toxicity. By offering the complete story we hope that our stakeholders will be able to use this document as a tool that will translate the environmental performance of Marmoleum into the true value and benefits to all our customers and stakeholders alike. For more information visit: www.forbo-flooring.com

Open the catalog to page 1

This declaration is an environmental product declaration in accordance with ISO 14025 and EN15804 that describes the environmental characteristics of the aforementioned product. It promotes the development of sustainable products. This is a certified declaration and all relevant environmental information is disclosed. This EPD may not be comparable to other declarations if they do not comply with ISO 14025, EN 15804 and the reference PCR.

Open the catalog to page 2

Marmoleum tile 2.0 and 2.5 mm Resilient Linoleum Floor Covering Product Definition Product Classification and description This declaration covers a broad range of designs and colors. Marmoleum is a resilient floor covering complying with all the requirements of EN-ISO 24011: Specification for plain and decorative linoleum. Marmoleum is made from natural raw materials making it preferable ecological floor covering with a beautiful and colorful design. The key raw materials include linseed oil, which comes from the flax plant seeds, gum rosin from pine trees, recycled wood waste of wood from...

Open the catalog to page 3

Environmental Product Declaration FLOORING SYSTEMS Marmoleum tile 2.0 and 2.5 mm Resilient Linoleum Floor Covering According to ISO 14025 & EN 15804 Product Standard The products considered in this EPD have the following technical specifications: o Meets or exceeds all technical requirements in ASTM F 2195 Standard Specification for Linoleum Floor Tile. o Meets or exceeds all technical requirements in EN-ISO 24011 Specification for plain and decorative Linoleum. Marmoleum meets the requirements of EN 14041 EN 13501-1 Reaction to fire Cfl - s1 Fire Testing: o Class 1 when tested in...

Open the catalog to page 4

Environmental Product Declaration (fodbo FLOORING SYSTEMS Marmoleum tile 2.0 and 2.5 mm Resilient Linoleum Floor Covering According to ISO 14025 & EN 15804 Delivery Status Table 1: Specification of delivered product Production of Main Materials Linseed oil : Linseed oil is obtained by pressing the seeds of the flax plant. After filtering a clear golden yellow liquid remains. Gum rosin : Rosin is obtained by wounding pine trees. The crude gum is collected and is separated into turpentine and rosin by distillation. Tall oil : Tall oil is a post industrial waste product coming from the...

Open the catalog to page 5

Marmoleum tile 2.0 and 2.5 mm Resilient Linoleum Floor Covering Production of the Floor Covering Figure 2: Illustration of the Production process Marmoleum tile is produced in several stages starting with the oxidation of linseed oil mixed with tall oil and rosin. With the influence of oxygen from the atmosphere a tough sticky material is obtained called linoleum cement. The linoleum cement is stored in containers for a few days for further reaction and after this it is mixed with wood flour, calcium carbonate, reused waste (if applicable), titanium dioxide and pigments. This mixture is...

Open the catalog to page 6

Environmental Product Declaration FLOORING SYSTEMS Marmoleum tile 2.0 and 2.5 mm Resilient Linoleum Floor Covering According to ISO 14025 & EN 15804 Rejected material and the cuttings of the trimming stage are being reused in the manufacturing process. Packaging materials are being collected separately and externally recycled. Delivery and Installation of the Floor Covering A worldwide distribution by truck and container ship is considered. On average every square meter of Marmoleum is transported as follows: o T ransport distance 40 t truck 694 km o Transport distance 7.5t...

Open the catalog to page 7

Environmental Product Declaration Marmoleum tile 2.0 and 2.5 mm Resilient Linoleum Floor Covering According to ISO 14025 & EN 15804 can be determined. The use phase impacts should be calculated with the foreseen service life to arrive at the total environmental impact. For the calculations the following cleaning regime is considered: 2 - Dry cleaning with a 1.5 kW vacuum cleaner for 0.21 min/m , twice a week. This equates to 0.55 kWh/m2*year. - Once a week wet cleaning with 0.062 l/m2 water and 0.0008 kg/m2 detergent. This result in the use of 3.224 l/m2*year water and 0.04 kg/m2*year...

Open the catalog to page 8

Marmoleum tile 2.0 and 2.5 mm Resilient Linoleum Floor Covering Life Cycle Assessment A full Life Cycle Assessment has bee carried out according to ISO 14040 and ISO 14044. The following Life Cycle Stages are assessed : o Production Stage (Raw material acquisition, transportation to Manufacturing and Manufacturing) o Transport Gate to User o Installation Stage o Use Stage o End of Life Stage Production Raw Material Extraction and Processing Installation loss Coating, Calendaring, Transport Drying, Energies with regional reference End-of Life Cleaning regime Figure 3: Flow chart of the Life...

Open the catalog to page 9

Marmoleum tile 2.0 and 2.5 mm Resilient Linoleum Floor Covering Allocation of multi-input processes The Production and End of Life stage include incineration plants. In these processes different products are treated together within a process. The allocation procedures followed in these cases are based on a physical classification of the mass flows or calorific values. Credits from energy substitution are allocated to the production stage, because the gained energy from energy substitution is lower than the energy input in this stage. The same quality of energy is considered. Allocation...

Open the catalog to page 10All Forbo Flooring Systems catalogs and technical brochures

-

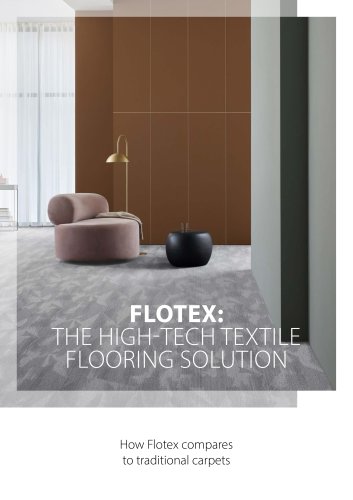

FLOTEX

12 Pages

-

Bulletin Board

11 Pages

-

Marmoleum Click

9 Pages

Archived catalogs

-

Colorex Life sciences

5 Pages

-

Colorex ELECTRONICS

5 Pages

-

Colorex automotive

5 Pages

-

Modul’up 19dB / Modul’up compact

16 Pages

-

showtime

25 Pages

-

TOPSHIELD2

4 Pages

-

TRANSPARENCY SUMMARY SMARAGD

2 Pages

-

TRANSPARENCY SUMMARY ETERNAL

2 Pages

-

EPD SMARAGD

42 Pages

-

EPD ACOUSTIC VINYL

40 Pages

-

EPD MARMOLEUM DECIBEL

44 Pages

-

EPD MARMOLEUM 2.0 AND 2.5MM

53 Pages

-

FORBO LIFE SCIENCES

5 Pages

-

FLOTEX BY TIBOR

24 Pages

-

SARLON ACOUSTIC VINYL BROCHURE

20 Pages

-

Furniture linoleum

13 Pages

-

TRUE TO NATURE allura magazine

31 Pages

-

Sphera® homogeneous vinyl

16 Pages

-

THE NEXT GENERATION OF MARMOLEUM

37 Pages

-

MARMOLEUM MODULAR TEXTURA

2 Pages

-

MARMOLEUM AQUAJET

24 Pages

-

Step safety vinyl

24 Pages

-

Coral entrance flooring

15 Pages

-

MARMOLEUM SPORT

11 Pages

-

CHO brochure

9 Pages

-

Marine Brochure

8 Pages

-

Bus & Coach Brochure

20 Pages

-

Rail Brochure

15 Pages

-

Sarlon Modul'Up brochure

20 Pages

-

Allura LVT brochure

14 Pages

-

Marmoleum Textura Leaflet

1 Pages

-

MARMOLEUM MODULAR

19 Pages

-

Flotex brochure

32 Pages

-

Marmoleum Meets Mendini

46 Pages

-

Westbond

8 Pages

-

Decorative Linoleum Flooring

24 Pages

-

Showtime®

40 Pages

-

Needlefelt

20 Pages

-

COLOREX BROCHURE

26 Pages

-

FORBO MARMOLEUM MAGAZINE

37 Pages

-

ACOUSTIC

16 Pages