Website:

FITT Spa

Website:

FITT Spa

Group: FITT Group

Catalog excerpts

fitt blutech Pressurised fluid transport

Open the catalog to page 1

fitt bLUTECH Pressurised fluid transport

Open the catalog to page 3

FITT, a leading global group established in Italy in 1969 - and today a Benefit Company - is a pioneer in the production and development of solutions for the transfer of fluids for domestic, professional and industrial applications. Ongoing progress The mission of the FITT group is to improve the performance of its customers by providing pipes, hoses and systems for the transport of liquid, gaseous and solid substances, with products at the forefront of technology, design and sustainability. FITT, currently led by Alessandro Mezzalira, was founded in 1969 by his father Rinaldo. With...

Open the catalog to page 4

Innovative and pioneering technology FITT Solutions FITT strongly believes in Open Innovation and works with an international network of partners, universities and research bodies, taking advantage of external organisations for the validation of its own quality tests and protocols, defining the impact of its products. FITT develops state of the art solutions for the handling of fluids, ensuring reliability, safety, performance and ease of use applicable to 9 dedicated and specialised business units. Multiplant production and logistics Flexible logistics, automated and customised, capable of...

Open the catalog to page 5

«The task that we are called to fulfil must contribute to make this world a better place, for us and for future generations» Alessandro Mezzalira CEO THE RESPONSIBLE FLOW: FITT’S SUSTAINABILITY STRATEGY FOR 2030 The FITT journey Corporate responsibility In FITT’s vision, being a responsible company means transforming its business model to achieve an ideal balance, with the objective of creating economic value and having a positive impact on the planet and on people’s lives. FITT is committed to producing state-oftheart products, providing its customers with the best technologies in the...

Open the catalog to page 6

FITT is engaged on two parallel fronts: the management of energy, water and waste, and the development of innovative products. FITT is engaged again on two complementary fronts, one internal and one external. In the area of processes, the most important objective is decarbonisation, with the aim of setting CO2e reduction targets (scopes 1-2-3), to be reached by the FITT GROUP by 2025. With this in mind, in 2023 FITT has started measuring its Carbon Footprint in accordance with the ISO 14064 GHG inventory. As far as sustainable development is concerned, the aim is to make sure that by 2025...

Open the catalog to page 7

FITT Blutech THE PVC PIPE FOR PRESSURISED FLUID TRANSPORT FITT Blutech is the ideal PVC pipe for the transport of pressurised fluids. PVC is the most suitable water supply and distribution pipe material, as it offers superior performance compared to other materials, especially when buried in marshy or brackish soils. PVC is impervious to most solutions containing acids, bases and salts with which it comes into contact during use, preventing the internal surface Scan the QR-Code to find out more! from being attacked by lime scale. This ensures the long-term preservation of the optimal...

Open the catalog to page 8

The FITT Blutech piper ensures: • Excellent water flow characteristics • Reduced susceptibility to fouling due to an inner surface that is not prone to mud and scale deposits • High strength and resistance to external loads • Good flexibility • Resistance to chemical and electrochemical aggression • Abrasion resistance • Ease of installation and assembly • Good quality/price ratio The FITT Blutech complies with: • The requirements of Technical Document Ki-0410, Annex K02 based on the UNI EN ISO 1452-2:2010 and EN 1622:2006 standards, and is, therefore, Kiwa-UNI-marked on the basis of type...

Open the catalog to page 9

Advantages of the integrated seal PowerLock®, the joint system that ensures perfect long-term stability and functionality of the seal FITT Blutech features a socket based joint system with integrated gasket, mechanically pre-inserted during the hot formation of the socket based joint. The PowerN 3000 Lock® gasket consists of a sealing element in EPDM elastomer according to UNI EN 681, co-moulded to a fibre-reinforced polypropylene 2000 stiffening Nring. 3000 1000 2000 This jointing systems ensures the absolute stability of the gasket, and therefore easy assembly, perfect functionality and...

Open the catalog to page 10

The advantages offered by Power Lock® can be seen by all the operators in the sector: DESIGNERS • High gasket performance • Time savings during checks and tests • Hydraulic tightness in case of both positive and negative pressure • Higher joint reliability • 3.0° angular deflection at the joint (high offset) • Internal socket based joint sizes non-susceptible to variations. INSTALLERS • The pipe is delivered with the gasket already fitted, therefore avoiding any loss or damage of the same • No gasket movement • Easy, fast and safe assembly • Considerable reduction in assembly force - which...

Open the catalog to page 11

Test report The IIP test reports show superior performance compared to the parameters of the standard of reference As a rule, the joint is the weakest point in a traditional laid pipeline. However, thanks to its unique PowerLock® jointing system, FITT Blutech boasts excellent tightness capabilities even under extreme operating conditions. To prove the technical superiority of FITT Blutech, FITT requested the Italian Plastics Institute (IIP) to perform rigorous leak tests that demonstrated the capability of the pipe to withstand more severe stress conditions than those contemplated by the...

Open the catalog to page 12

Specification item Supply of unplasticized rigid PVC-U pipes for transporting pressurised fluids, buried and above ground, compliant with the UNI EN ISO 1452 standard. The pipes must also comply with Ministerial Decree of 21/03/1973 (liquid foods), Ministerial Decree no. 174 of 06/05/2004 (water for human consumption) and the requirements of the UNI EN 1622 standard: “Water analysis - Determination of odour threshold (TON) and flavour threshold (TFN)”. The pipes must be extruded from plasticiser-free polyvinyl chloride blends, with the only addition of heavy-metal-free organic OBS...

Open the catalog to page 13All FITT Spa catalogs and technical brochures

-

EPD FITT Sewer Evo

52 Pages

-

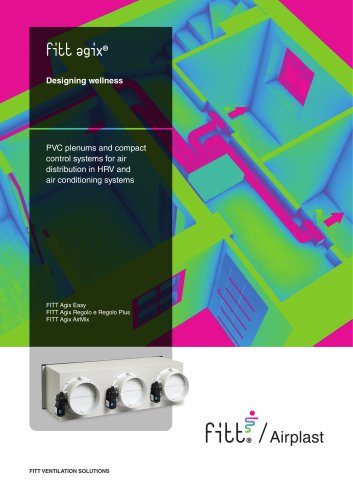

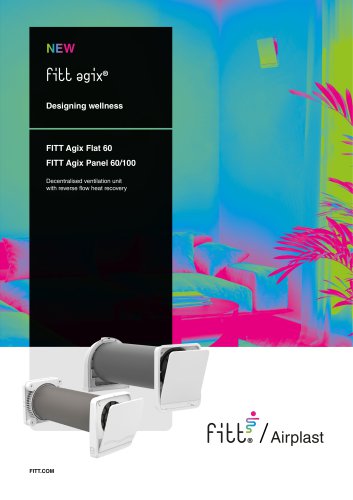

FITT Agix

122 Pages

-

FITT REVIX

4 Pages

-

FITT Pool&SPA Solutions

24 Pages

-

FITT Extra White

1 Pages

-

FITT Refittex White

1 Pages

-

FITT Evapool

1 Pages

-

FITT Idroflex

1 Pages

-

FITT Barrier CDS

1 Pages

-

FITT B-Active Flex

2 Pages

-

FITT B-Active Rigid

2 Pages