Website:

FINSA

Website:

FINSA

Group: FINSA

Catalog excerpts

PCT / EP99 / 09984 EUROPEAN PATENT OFFICE The structural board by FINSA

Open the catalog to page 1

ABOUT FINSA After over 80 years dedicated to wood processing, we remain committed to continue more technical and precise products. With great enthusiasm and backed by extensive experience in the development of wood-based products, we want to share with you the advantages of using technical wooden boards in your projects, and share our commitment to the future of this material. A new generation of technical wood manufactured by FINSA through a process of continuous pressing. An innovative and exclusive product protected by patent no. PCT/EP99/09984 (European Patent Office) Superpan is made...

Open the catalog to page 2

SUPERPAN TECH P6 A high-performance and high-strength wooden board. Ranked as P6 technical class structural board; heavy duty loadbearing boards for use in dry conditions, is a unique solution in the structural panels market. Wood particles Ranked as a P4, load-bearing boards for use in dry conditions. Wood fibre High mechanical strength Equal resistance in any direction of the board Fast and easy installation with conventional woodworking tools Significant savings in installation time and costs Excellent value for money Versatility of formats Wide variety of coating possibilities Smooth...

Open the catalog to page 3

Superpan Tech P4 TECHNICAL FEATURES TEST These physical-mechanical values improve/comply with the P4 classification established in EN 312:2010 European Standard. Table 1 and Table 6: Load-bearing boards for use in dry conditions. MECHANICAL PROPERTIES (according to EN 12369-1) DURABILITY Superpan Tech P4 boards are suitable for Service Class 1 and Class of Use 1 according to EN 312. REACTION TO FIRE Class D-s2, d0 or DFL -s1 according to standard EN 13986. PHYSICAL PROPERTIES Thermal conductivity: 0.12 W/m°K, according to standard EN 13986. Specific heat: 1700 J/kg°K. Resistance factor to...

Open the catalog to page 4

CERTIFICATIONS Superpan Tech P6 has the following certifications: CE Marking Issued by AENOR No. 0099/CPD/A65/0008 MECHANICAL PROPERTIES (according to EN 12369-1) AITIM 24/04/04 quality seal Chain of custody certification PEFC number 14-35-00006 FSC number TT-COC-003279 The mechanical properties of Superpan Tech P6 boards have been tested according to EN 789 in the laboratory of the Joint Unit INIA-AITIM, in April 2012, having achieved the following values: These physical-mechanical values improve/comply with the P6 classification established in EN 312:2010 European Standard. Table 1 and...

Open the catalog to page 5

APPLICATION GUIDE (according to ENV 12872:2000) STACKING Boards should be stacked horizontally upon flat surfaces, conveniently away from the ground and with a sufficient number of supports to prevent the lower panels from overload. Intermediate battens are recommended between every 15 to 20 panels for ventilation, in line with the lower vertical battens. It is recommended that the battens are placed parallel to the shorter sides and along the entire length of the stack. It is recommended that the ends do not exceed 150 mm. When packets are stacked, it is recommended that the supports...

Open the catalog to page 6

CUTTING AND PROFILING The machining quality of the surfaces decreases with increased moisture contents. When greater precision is required, it is recommended that the boards be cut to size after packaging according to the moisture content of the end use. Mechanization with power tools The use of carbide or diamond tools and blades is recommended for increased service life. Saw blades with alternating teeth are recommended. It is recommended that circular saw discs are placed as low as possible in order to prevent chipping when the board comes out the back of the saw. If the speed is too...

Open the catalog to page 7

USE IN MEZZANINES AND FLOOR SLABS The choice of boards for floor slab structural enclosures upon beams depends on the required load stresses, spans, mechanical characteristics and class of service. We recommend using wood-based panels only for floor slab enclosures in conditions corresponding to service class 1. min. 8 mm STARTING TO WORK Structure preparation It is recommended to align and level supporting edge joists, studs and braces. It is recommended that wood, wood-based panels and structural elements not be unnecessarily exposed to more severe climate conditions than those they will...

Open the catalog to page 8

MOUNTING SUPERPAN TECH IN FLOOR SLAB ENCLOSURES We recommend placing tongue and groove boards transversely to the joists, with their shorter sides supported on a joist or upon any other edge support. It is recommended that straight edged boards be continuously supported on all four sides with the shorter sides supported upon joists and the larger ones upon crossbars or joint-covers. All perimeter edges of the board or those obtained from cutting should be supported by studs or joists. It is recommended that the joints of the smaller side of the boards are placed alternately, for whatever...

Open the catalog to page 9

Industrial mezzanines and industrial storage solutions

Open the catalog to page 10

FINSA solutions in wood

Open the catalog to page 12All FINSA catalogs and technical brochures

-

Workplace

42 Pages

-

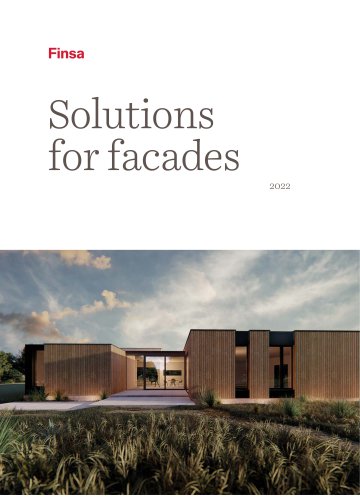

Solutions for facades

114 Pages

-

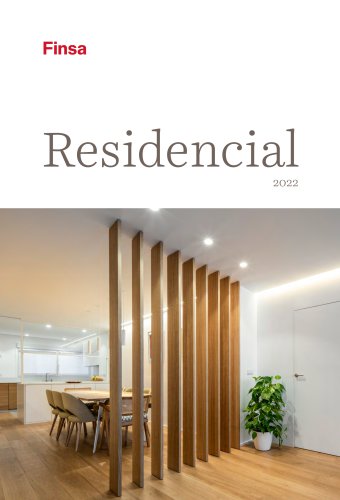

Residencial 2022

35 Pages

-

FINFLOOR CATALOGUE 2022

86 Pages

-

INSPIRATIONAL CATALOGUE 2022

77 Pages

-

CONSTRUCTION SOLUTIONS

210 Pages

-

FIBRACOLOUR & TEXTURES

28 Pages

-

FINSA INFINITE TRICOYA

36 Pages

-

Gama duo

100 Pages

-

HOSPITALITY FINSA PORTFOLIO

45 Pages

-

FINTOP LAM

1 Pages

-

Purefloor

1 Pages

-

SuperPan FD30

2 Pages

-

THERMOPINE

24 Pages

-

SuperPan

34 Pages

-

FIBRACOLOUR Design

15 Pages

-

FIBRACOLOUR Technical

15 Pages

-

high gloss

2 Pages

-

Purefloor

8 Pages

-

States of mind and matter

122 Pages

-

EXPRESS RANGE

2 Pages

-

STUDIO NATUR

41 Pages

-

Finfloor LVT

17 Pages

-

Superpan Tech P5

20 Pages

-

Gama Studio

44 Pages

-

SuperpanTech Encoform

12 Pages

-

Light solutions in wood

20 Pages

-

gama duo

16 Pages

-

COMPACMEL PLUS

52 Pages

-

Presentation

36 Pages

-

Supreme

2 Pages

-

FINfloor

89 Pages