Catalog excerpts

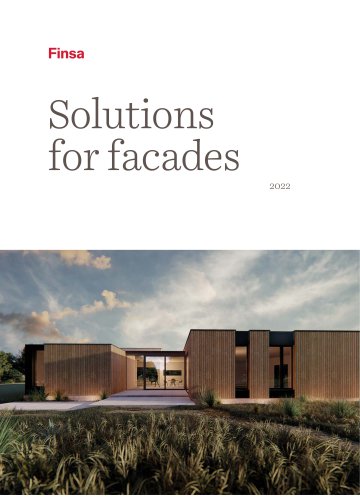

We are Finsa Finsa in numbers Sustainability Savia Thermopine Savia Facades with Thermopine Savia What is Thermopine Savia Heat treatment Categories Process Steps Properties Self-reported carbon footprint CTE DB SI Compliance Use class Range of claddings Standard façade profiles Installation accessories Cuts and finishing Quality criteria Installation Lag screw specifications Construction details Natural ageing Cleaning and maintenance Technical characteristics Thermopine UTV specification Thermopine 3D specification Gradpanel by Thermopine Savia Pictograms guide Efficiency and...

Open the catalog to page 5

Finsa is a company that manufactures technical wood solutions. With almost 90 years of history, it has evolved and positioned itself as one of the leading brands in the sector. Over the years, the company has become more advanced, incorporating new materials and adapting to the new times, while retaining its essence and its main values of sustainability and design. Founded in 1931 as a small sawmill, it has been a pioneer in the manufacture of chipboard and MDF on the Iberian Peninsula, maintaining steady growth from 1931 until today. In recent years, investments have been focused on...

Open the catalog to page 9

According to the latest data for 2019. Cargo ships Local branches Logistics warehouses Lorries with real-time GPS From its beginnings as a small sawmill in 1931, Finsa has gradually grown into a global company. Today, we have 18 of our own branches and, through our export department, we can reach more than 80 countries all over the world. Our commitment to our customers does not end with the manufacture of quality products. We manage your delivery by land or sea, ensuring that it’s on time and in perfect condition, thanks to a large logistical network. In addition, we are continuously...

Open the catalog to page 11

Sustainability Credits for environmental certifications Finsa materials are made from wood, which is a renewable, recyclable, sustainable material. Using our products in construction projects contributes to the obtaining of credits for LEED, BREEAM or VERDE certification seals. These certify the environmental performance of products and systems and, therefore, their contribution to the environmental quality of buildings. Certifications: Wood from sustainable forests The Chain of Custody certifies the movement of raw materials from the forest to the consumer/customer, at all stages of the...

Open the catalog to page 13

Savia is dedicated to the transformation and commercialization of solid wood, is part of Finsa and specializes in the development of solutions and new products in close collaboration with its customers. Experience, production and logistics capacity, human resources and an innovative mindset focused on the development of new solutions in wood: these are values that we have inherited from our industrial group. With all these backgrounds, Savia was born: a company that seeks to open new paths for solid wood, with innovative proposals and developments adapted to current needs. In addition to...

Open the catalog to page 15

Façades with Savia Thermopine As part of its mission to offer wood solutions for architecture and interior design, in recent years, Finsa has developed a durable, non-toxic wood cladding solution for façades that has a low impact on the environment and is sustainable: Savia Thermopine heat-treated pine. The dimensional stability that characterizes this material makes it ideal for façade application, allowing the designer to bring the warmth of high-performance wood to the façade of the building, and providing a skin that is natural and 100% recyclable. UTV channel profile ThermoPine façade....

Open the catalog to page 19

What is Savia Thermopine? Shou Sugi Ban is a traditional Japanese technique that is more than three centuries old. It consists of applying a thermal treatment to wood in order to improve its performance in outdoor environments. This process carbonises the outer layers of the wooden boards, creating a barrier and protecting them from degradation caused by fungi and xylophagous insects. In line with this philosophy, at the beginning of the 20th century, the first scientific studies on the heat treatment of wood were carried out (Tiemann, 1920). While carrying out research on drying at high...

Open the catalog to page 20

Heat treatment The ThermoPine manufacturing process is very environmentally friendly, as it does not use any toxic or polluting products. In order to achieve the thermal modification of the wood, we only use temperatures between 190ºC and 210ºC, depending on the type of heat treatment, and water vapour, all within a vacuum atmosphere that has no oxygen. Due to the degradation of some of the constituent molecules of the wood, such as terpenes or phenols, as a result of the effect of the temperature, a number of completely natural extracts are produced and managed effectively. Essentially, we...

Open the catalog to page 21

Categories Thermopine-S (Stability) Indoors The maximum temperature reached during thermal modification for Thermopine-S is 190°C. In this way, we achieve a nice light brown colour and a considerable improvement in dimensional stability due to the decreased equilibrium moisture content of the wood. It is usually applied indoors. Thermopine-D (Durability) 1 Untreated pine. 2 Thermopine-S. 3 Thermopine-D. The maximum temperature reached during thermal modification of Thermopine-D is 210ºC. With this temperature level, we achieve an elegant dark brown colour. The dimensional stability and...

Open the catalog to page 22

Process stages for heat treatment Stage 1 In this stage, the wood is gradually heated using heat and steam until it reaches temperatures of between 150ºC and 180ºC. At the same time, high temperature drying also takes place, causing a significant decrease in the moisture content of the wood, close to 0%. Heat treatment Once the wood is prepared with the appropriate moisture content, the temperature of the chamber is increased again from 190ºC to 210ºC, depending on the type of heat treatment being carried out. This process uses steam and vacuum to avoid igniting the wood. The duration of...

Open the catalog to page 23All FINSA catalogs and technical brochures

-

catalogo purefloor 2024

23 Pages

-

Workplace

42 Pages

-

Residencial 2022

35 Pages

-

FINFLOOR CATALOGUE 2022

86 Pages

-

INSPIRATIONAL CATALOGUE 2022

77 Pages

-

CONSTRUCTION SOLUTIONS

210 Pages

-

FIBRACOLOUR & TEXTURES

28 Pages

-

FINSA INFINITE TRICOYA

36 Pages

-

HOSPITALITY FINSA PORTFOLIO

45 Pages

-

FINTOP LAM

1 Pages

-

SuperPan FD30

2 Pages

-

THERMOPINE

24 Pages

-

SuperPan

34 Pages

-

FIBRACOLOUR Design

15 Pages

-

FIBRACOLOUR Technical

15 Pages

-

high gloss

2 Pages

-

States of mind and matter

122 Pages

-

EXPRESS RANGE

2 Pages

-

STUDIO NATUR

41 Pages

-

Finfloor LVT

17 Pages

-

Superpan Tech P5

20 Pages

-

Gama Studio

44 Pages

-

SuperpanTech Encoform

12 Pages

-

SuperpanTech P4-P6

12 Pages

-

Light solutions in wood

20 Pages

-

COMPACMEL PLUS

52 Pages

-

Presentation

36 Pages

-

Supreme

2 Pages

-

FINfloor

89 Pages

Archived catalogs

-

2020 Gama duo

100 Pages

-

Purefloor 2018

8 Pages

-

gama duo

16 Pages