Catalog excerpts

ENERCON wind energy converters Technology & Service

Open the catalog to page 1

Technology & Service ENERCON turbine technology <■> 2 ENERCON WEC control system 16 3 ENERCON grid integration and wind farm management 20 4 ENERCON remote monitoring 30 6 ENERCON product overview 40

Open the catalog to page 2

Technology & Service ENERCON has been among the top producers of wind energy converters for nearly 30 years company's success are innovation and quality Both highly developed vertical integration and a comprehensive quality management system play a significant role in securing ENERCON's high quality standards Through constant product enhancement and sophistication of the turbine components ENERCON's main objective is to provide its cus- tomers with state-of-the-art products. A tight-knit team of engineers specialised in various fields is constantly working on setting technological...

Open the catalog to page 3

ENERCON turbine technology [Aurich]

Open the catalog to page 4

1. ENERCON turbine technology ENERCON turbine technology The performance and reliability of the gear- less drive system combined with an effi- ciently streamlined rotor blade design provide for optimal returns on investment. Rotor blades When it comes to yield, noise emission and stress minimisation, ENERCON's rotor blade concept has set new standards in the wind energy sector. Due to their modified shape, the blades now not only draw energy from the outer edges of the swept area but also make more efficient use of the inner radius - considerably increasing power output. The new rotor...

Open the catalog to page 5

1. ENERCON turbine technology Annular generator technology Amongst other features, the annular generator is a key component in ENERCON's gearless wind generator design. Combined with the rotor hub it provides an almost frictionless flow of energy while a smaller number of moving components ensure minimum material wear Unlike conventional fast-running generators, ENERCON's annular generator is subjected to little mechanical wear, making it ideal for particularly heavy loads and guaranteeing a long service life It is a low-speed synchronous generator with no direct grid coupling. Output...

Open the catalog to page 6

1. ENERCON turbine technology Tower construction The load-dynamic design of the materials and structure used in ENERCON towers provides the best conditions for transport, installation and use. Over and above the binding national and international norms (e.g. DIN and Eurocode] ENERCON sets its own standards which raise the bar in terms of quality and safety Virtual 3D models of the tower designs are produced during the development phase using the finite element method (FEM). All possible stress factors on the wind turbine are simulated on the model. This means that accurate predictions...

Open the catalog to page 7

1. ENERCON turbine technology Steel towers ENERCON tubular steel towers are manufactured in several individual tower sections connected by means of stress-reducing L-flanges. Unlike con- ventional flange joints, the welding seam of the L-flange lies outside the stress zone ENERCON steel towers are connected to the foun- dation either by means of a specially developed foundation section or a foundation basket The cylindrical foundation section is set on the blinding layer, adjusted to the correct height and precisely aligned with adjusting bolts. Once the foundation is complete, the tower is...

Open the catalog to page 8

ENERCON WEC control system

Open the catalog to page 9

2. ENERCON WEC control system ENERCON WEC control system ENERCON wind turbines are equipped with state-of-the-art microelectronic control tech- nology developed in-house. Sensor system The MPU (main processing unit), the central elem- ent of the control system, is in constant contact with peripheral control elements such as the yaw control and active pitch systems. A large number of sensors continuously monitor the current status of the wind energy converter as well as all the rele- vant ambient parameters. The control system analyses the signals and re- gulates the wind energy converters...

Open the catalog to page 10

ENERCON grid integration and wind farm management

Open the catalog to page 11

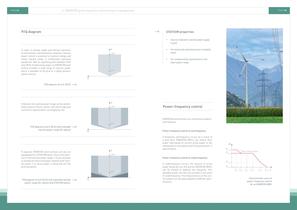

3. ENERCON grid integration and wind farm management ENERCON grid integration and wind farm management ENERCON wind energy converters are equipped with intelligent grid management technology. Fulfilling international grid code requirements, ENERCON WECs guar- antee reliable power feed in any networks Optimum grid integration ENERCON's grid management system is made up of a rectifier, DC Link and modular inverter system To ensure that the generated power is properly fed into the grid, voltage, current and frequency are constantly recorded at the point of reference and transmitted to the WEC...

Open the catalog to page 12

3. ENERCON grid integration and wind farm management h order to achieve stable and efficient operation of transmission and distribution networks, reactive power control is essential to maintain voltage and utilise reactive power to compensate operating equipment. With an operating point between 20% and 100% of rated active power, an ENERCON wind turbine provides a wide range of reactive power which is available to the grid as a highly dynamic system service If desired, the reactive power range can be extend- ed by means of the Q+ option, with which high grid connection requirements can...

Open the catalog to page 13

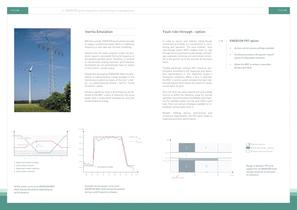

3. ENERCON grid integration and wind farm management Inertia Emulation With this concept, ENERCON wind turbines are able to support conventional power plants in stabilising frequency or even take over the task completely. Owing to the full-scale converter model, the gen- erator speed is decoupled from grid frequency to the greatest possible extent. Therefore, in contrast to conventional rotating machines, grid frequency fluctuations do not automatically have an impact on the turbine's power output Despite the decoupling, ENERCON offers the pos- sibility of making backup energy available to...

Open the catalog to page 14

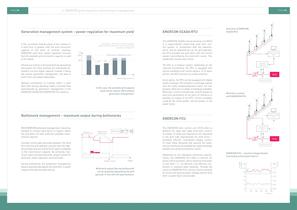

3. ENERCON grid integration and wind farm management Generation management system – power regulation for maximum yield If the cumulative (rated) output of the turbines in a wind farm is greater than the grid connection capacity at the point of common coupling, ENERCON wind farm power regulation ensures that the available grid connection capacity is used to the fullest. Grid capacity = 80 % of the installed cumulative rated power (this would be the feed-in limit without generation management) P Rated power installed per turbine The ENERCON SCADA remote terminal unit (RTU) is a superordinate...

Open the catalog to page 15All Enercon catalogs and technical brochures

-

ENERCON E-CHARGER 600

3 Pages

-

E-CHARGING PARK

2 Pages

-

E-138 EP3

18 Pages

-

Data Sheets Enercon

33 Pages

-

PRODUCT PORTFOLIO

2 Pages

-

EN_PUE_en_web

17 Pages