Catalog excerpts

WE MAKE INFRASTRUCTURE SAFER, STRONGER, AND SMARTER. ROCK BOLTS AND MESHES THIS BROCHURE IS VALID IN THE U.K. AND REPUBLIC OF IRELAND ONLY

Open the catalog to page 1

Contents About us 4 Stabilization vs. Drapery 5 Passive Drapery Systems 5 Stabilisation Systems 5 Rock Bolts 6 Basic Concept 6 GEWI® Threadbar 8 GEWI® Plus Threadbar 9 Accessories10 Expansion Shell Anchors / Rock Bolts with Expansion Shell 11 Meshes 12 Basic Concept 12 Key Features

Open the catalog to page 3

About us DYWIDAG-Systems International are a specialist geotechnical systems supplier with expert technical knowledge and long-standing experience in slope and rock face stabilisation. DYWIDAG-Systems International can provide advice and guidance on how changes can be made to increase the technical or economical efficiencies within the system. Through our strategic partnership with specialist Swiss manufacturer GEOBRUGG we are able to offer complete slope and rock face stabilisation solutions including: ■ Rock Bolts DYWIDAG-Systems International UK was established in 1967 and has provided...

Open the catalog to page 4

Stabilization vs. Drapery Passive Drapery Systems Drapery systems are used to mitigate the effects of rockfall without preventing it. This system aims to control the descent of falling rock by limiting the velocity/energy gained during descent. High Tensile Steel Mesh is used to provide a curtain, beyond which the falling rock cannot pass. Upon detachment from the face, the loose rock will impact on the mesh curtain and then rebound onto the rock face, each time dissipating energy and preventing large amounts of energy from accumulating. Drapery systems utilise bolts at the crest and...

Open the catalog to page 5

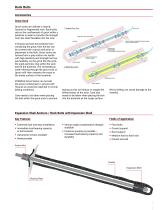

Rock Bolts Basic Concept Rock Bolts are generally formed from solid threadbar systems, i.e. bar, nut, couplers and plates. The steel threadbar is used to bond unstable rock to stable sections, beyond the face, and requires both capacity for tensile and shear loads. Rock bolts are fully bonded and unlike ground anchors are passive installations. Unless it has been severely weathered, rock will usually allow for an open hole to be drilled without any risk of collapse. Solid threadbars offer the most efficient means of transferring load and maintaining the smallest diameter borehole. Due to...

Open the catalog to page 6

Rock Bolts GEWI® GEWI® Steel High Yield Threadbars are formed from a high tensile alloy steel. The bars are manufactured with a coarse left-hand thread over their full length. GEWI® couplers can provide a 100% load transfer between lengths of bar. The bar is also manufactured with flats on either side; these allow the self removal of dirt or debris as the bar is threaded into any female accessory, preventing cross threading and making it ideal for geotechnical applications. GEWI® bar is manufactured in accordance with the German Certificate of Approval (Deutsches Institut für Bautechnik),...

Open the catalog to page 7

Rock Bolts GEWI® Threadbar Key Features ■ Left Handed Thread ■ Coarse Pitch Threadform (d/2), except 63.5mm ■ Standard Load Range Technical Data Nominal Diameter Steel Grade Ultimate Strength Yield Strength CrossSectional Area Diameter Over Threads Thread Pitch Accessories Nominal Diameter Static Coupler

Open the catalog to page 8

Rock Bolts GEWI® Plus Threadbar Key Features ■ Right Handed Thread ■ Reduced Pitch Threadform (d3) ■ Increased Load Range Capacity Technical Data Nominal Diameter Steel Grade Ultimate Strength Yield Strength CrossSectional Area Diameter Over Threads Thread Pitch Accessories Nominal Diameter Static Coupler

Open the catalog to page 9

Rock Bolts Accessories Bearing Plates Bearing plates have a dual purpose: as well as acting as a reaction surface to material moving against the head of the plate, and it secures and transfers load from any facing system into the rock bolts. Size and thickness of the head plate need to be determined during the design phase as each project requires a different plate and it should not be assumed that they are standardized parts. However, for rock bolting, plates tend to be smaller but thicker as bearing failure below the plate is rarely an issue. the plate and the rock bolt; different plates...

Open the catalog to page 10

Rock Bolts Accessories Grout Sock Grout socks are utilised in heavily fissured or fragmented rock. Rock bolts rely on the confinement of grout within a borehole in order to transfer the strength from the steel threadbar into the rock. If fissures prevent the borehole from containing the grout, then the bar can be covered with a grout sock prior to placement in the hole. Grout socks are formed from a poly-cotton mix textile with high elasticity and strength but low permeability. As the grout fills the sock, the solid particles clog within the sock and fill the borehole. The cementitious...

Open the catalog to page 11

Meshes Basic Concept DYWIDAG-Systems International through partnership with specialist Swiss Geohazards solution provider GEOBRUGG offer a range of high-tensile steel, flexible facing meshes. GEOBRUGG have vast experience in reducing the impact of rock fall and developed their first Avalanche Protection Structure made of wire rope net in 1951. These avalanche prevention structures were exposed to rockfalls during snow-free periods, and they succeeded in holding these rocks. Following the success of the Avalanche Barriers, GEOBRUGG developed the TECCO® SYSTEM3. The first mesh was made from...

Open the catalog to page 12

Meshes Accessories The TECCO® SYSTEM3 has been designed to ensure that all the individual components work in harmony to transfer loads efficiently over the entire system. The relationship between the TECCO® Mesh, the Spike Plates and the TECCO® clip T2 & T3 provides a comprehensive facing solution. The TECCO® SYSTEM3 has been designed, tested and approved with the full details covered in the European Technical Approval. Product DELTAX / GREENAX ® European Technical Approval ETA 17/0116 TECCO G65 Stainless Steel Technical Data Roll Size Punching Strength Wire Diameter ULTRACOATING...

Open the catalog to page 13

Geocomposites Basic Concept The Geobrugg mesh range includes two products that are specifically designed for weathered rock or soil retention. TECCO® GREEN (G65/3) and GREENAX® incorporate a threedimensional polypropylene erosion control mat into the high-tensile steel wire mesh. The integrated, reinforced composite is suitable for temporary and permanent erosion control. These Geocomposite products can be used on slopes, embankments and cuttings where vegetation is to be encouraged. The three-dimensional erosion control mat provides an ideal environment for the vegetation to grow, even in...

Open the catalog to page 14All DYWIDAG-Systems International (DSI) catalogs and technical brochures

-

STAY CABLE BRIDGE

13 Pages

-

ANCHOR SYSTEMS

20 Pages

-

POST-TENSIONING SYSTEMS

32 Pages

-

Accessories for Concrete Structures

152 Pages