Catalog excerpts

Model JN Semi-Automatic Dough Divider/Rounder Expandable Pocket Design General Safety, Installation, Instruction & Parts Manual NSF, USDA, UL Listed 4 Machines in 1 Capability 36, 18, 9 & 6-Part Divisions 1-ounce up to 26-ounces each piece “Dutchess . . . Proven Leadership through Research & Development”

Open the catalog to page 1

“DUTCHESS ALL-AMERICAN” MODEL JN Semi-Automatic Dough Divider/Rounder NSF, USDA, UL LIsted - Patented TABLE OF CONTENTS General Rules Machine Specifications Uncrating Installation Operating Instructions Adjustments Head Removal Head Replacement Head Cleaning Machine Cleaning Maintenance Lubrication Troubleshooting Dough Scaling Charts (English & Metric) Assembly Drawing / Parts Listings Head Assemblies Electrical Schematic Safety Labels © 2009 Dutchess Bakers’ Machinery Company, Inc. 302 Grand Avenue, Superior, WI 54880-0039 DUTCHESS TOLL FREE CUSTOMER SERVICE HOTLINE: 1-800-777-4498

Open the catalog to page 2

General Rules GENERAL SAFETY RULES: 1. Equipment should not be operated with safety devices or guards removed. 2. Only qualified personnel should operate this machine. 3. Machines should not be started until all personnel are clear. 4. Service and maintenance procedures should never be performed on a machine in motion. 5. To avoid shock or serious injury, only qualified personnel should perform maintenance on the electrical system. 6. The electric power MUST be OFF before servicing the machine. GENERAL OPERATING RULES: 1. DO NOT operate this machine until you read and understand the...

Open the catalog to page 3

SERVICE & MAINTENANCE: 1. DO NOT service a machine until you are thoroughly qualified, trained and familiar with the tasks to be performed. 2. Never operate any controls while other persons are performing maintenance on the machine. 3. DO NOT bypass a safety device. 4. Always use the proper tool for the job. 5. Never open covers with power on. 6. Electrical power switch is to be turned off, and machine disconnected from the power source, unless absolutely required for a specific service being performed. ELECTRICAL: 1. All electrical maintenance and service should be performed only by...

Open the catalog to page 4

"DUTCHESS ALL-AMERICAN" MODEL JN Semi-Automatic Dough Divider/Rounder Machine Specifications Machine: Weight (with 36-part head) Size (without handle) 450 lb. (168 Kg.) Width: 26-1/2" (673 mm) Depth: 22" (558.8 mm) Height: 60" (1524 mm) Divider Head w/2 same division Dough Pallets: Head Part Number Dough Pallets: Pallet Part Number Part Number Electrical: Standard:

Open the catalog to page 5

UNCRATING This unit weighs 450 pounds, and proper equipment must be used to lift and move. 1. Set the total carton, with machine, on a flat, level surface. CAUTION! Carton staples are sharp - use proper tools to remove staples. Do not pull flaps by hand before removing staples! 2. Cut carton at dotted line at bottom. Lift carton over machine, and remove plastic bag. 3. The rear and side covers on the machine must be removed. Turn the two latches ¼ turn and top edge will move outward. Lift cover upward off retainers. IMPORTANT The covers must be reinstalled on the machine after installation!...

Open the catalog to page 6

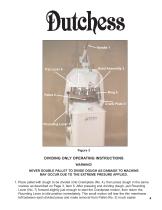

2. Set machine in place with bolts and/or studs properly set and tightened. Seal around the base with an approved silicone sealant, GE RTV 102 or equal. 3. Each machine must be direct wired. See proper wiring diagrams on pages 33 - 32. CAUTION! All electrical connections should be installed by an electrician. All state, local and national electrical codes MUST be complied with. 4. Reinstall side covers. 5. Install handle, with hole topside, fully into socket on ram lever. Tighten supplied set-screw, through hole in handle, with hex key wrench. (See Figure 2 below) 6. Apply a thin coat of...

Open the catalog to page 7

3. Flip the power switch to ON, and leave the motor running until the day's dividing/rounding is complete. 4. Place pallet (No. 2) with weighed dough onto the crankplate (No 4). CAUTION! The pallet must fit snugly and flat on the crankplate with the handle in the forward position. Damage will occur to pallet, divider, and/or crank plate, if pallet is not in proper position. 5. Pull handle (No. 1) down, lowering ring (No. 5) until head assembly (No. 3) comes in contact with the dough. Now it is important for you to exert firm, even pressure on the dough for 3-4 seconds, by pulling or pushing...

Open the catalog to page 8

DIVIDING ONLY OPERATING INSTRUCTIONS WARNING! NEVER DOUBLE PALLET TO DIVIDE DOUGH AS DAMAGE TO MACHINE MAY OCCUR DUE TO THE EXTREME PRESURE APPLIED. 1. Place pallet with dough to be divided onto Crankplate (No. 4), then press dough in the same manner as described on Page 3, Item 5. After pressing and dividing dough, pull Rounding Lever (No. 7) forward slightly just enough to start the Crankplate motion, then return the Rounding Lever to idle position immediately. This small motion will tear the thin membrane left between each divided piece and make removal from Pallet (No. 2) much easier. 4

Open the catalog to page 9

WARNING! Keep hands and clothing clear of all moving parts. EMERGENCY STOP In case of emergency, release rounding lever, flip power switch to OFF, and raise handle. ADJUSTMENTS All adjustments have been made at the factory, however, readjusting may be required upon installation, and periodically during use. 1. Your new Dutchess Divider/Rounder comes equipped with a "Expandable Pocket" design. Experimentation will be required to determine the correct pocket height for each size dough ball. To increase the pocket height, loosen the locking nut by turning counter clockwise. Turn the stop rod...

Open the catalog to page 10

1. Remove front and rear canopies (Fig. 7, No. 5 & No. 6) by lifting up, and out. 2. Pull handle (Fig. 7, No. 1), down until ring (No. 2) is resting on pallet (No. 3). 7. Set pocket height on the stop rod, Fig. 9, at least 1" off the trip plate. Release he trip lever (Fig 10, No. 1). INCREASE DECREASE Figure 7 WARNING! Do not release the handle from your hand, until the handle is returned to its uppermost position. 3. Hold handle in this position, grasp outer edges of the ring (Fig. 8, No. 1) keep fingers out of the divider/plug area. Rotate ring ¼ turn until slots are in line with the arms...

Open the catalog to page 11All DUTCHESS catalogs and technical brochures

-

Model DUT/V-80EL

2 Pages

-

DUT/TXM-20

1 Pages

-

DUT/M140-W

2 Pages

-

DUT/S-100

2 Pages

-

DUT/AV-01

2 Pages

-

DUT/TXM-15

2 Pages

-

DUT/DM-18

2 Pages

-

DUT/DMS-18

2 Pages

-

Model 270

2 Pages

-

Model JN

2 Pages

-

DUT/DXM-SS

2 Pages

-

Model 270C/270CE

2 Pages

-

Model 260

18 Pages

Archived catalogs

-

Model LD-626

6 Pages

-

FRENCH BREAD/BUN & BAGEL SLICER

20 Pages