Catalog excerpts

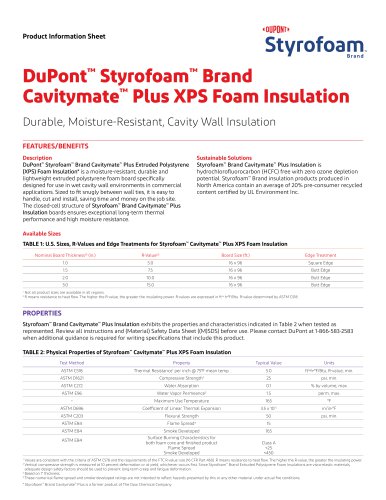

Product Information Sheet DuPont™ Styrofoam™ Brand Cavitymate™ Plus XPS Foam Insulation Durable, Moisture-Resistant, Cavity Wall Insulation FEATURES/BENEFITS Description DuPont™ Styrofoam™ Brand Cavitymate™ Plus Extruded Polystyrene (XPS) Foam Insulation* is a moisture-resistant, durable and lightweight extruded polystyrene foam board specifically designed for use in wet cavity wall environments in commercial applications. Sized to fit snugly between wall ties, it is easy to handle, cut and install, saving time and money on the job site. The closed-cell structure of Styrofoam™ Brand Cavitymate™ Plus Insulation boards ensures exceptional long-term thermal performance and high moisture resistance. Sustainable Solutions Styrofoam™ Brand Cavitymate™ Plus Insulation is hydrochlorofluorocarbon (HCFC) free with zero ozone depletion potential. Styrofoam™ Brand insulation products produced in North America contain an average of 20% pre-consumer recycled content certified by UL Environment Inc. Available Sizes TABLE 1: U.S. Sizes, R-Values and Edge Treatments for Styrofoam™ Cavitymate™ Plus XPS Foam Insulation Nominal Board Thickness(1) (in.) Edge Treatment Square Edge Butt Edge Butt Edge Butt Edge Not all product sizes are available in all regions. 2 R means resistance to heat flow. The higher the R-value, the greater the insulating power. R-values are expressed in ft2• h•°F/Btu. R-value determined by ASTM C518. 1 PROPERTIES Styrofoam™ Brand Cavitymate™ Plus Insulation exhibits the properties and characteristics indicated in Table 2 when tested as represented. Review all instructions and (Material) Safety Data Sheet ((M)SDS) before use. Please contact DuPont at 1-866-583-2583 when additional guidance is required for writing specifications that include this product. TABLE 2: Physical Properties of Styrofoam™ Cavitymate™ Plus XPS Foam Insulation Test Method Typical Value Thermal Resistance1 per inch @ 75°F mean temp. Water Absorption Coefficient of Linear Thermal Expansion Flexural Strength Smoke Developed Surface Burning Characteristics for both foam core and finished product Flame Spread Smoke Developed Values are consistent with the criteria of ASTM C578 and the requirements of the FTC R-value rule (16 CFR Part 460). R means resistance to heat flow. The higher the R-value, the greater the insulating power. Vertical compressive strength is measured at 10 percent deformation or at yield, whichever occurs first. Since Styrofoam™ Brand Extruded Polystyrene Foam Insulations are visco-elastic materials, adequate design safety factors should be used to prevent long-term creep and fatigue deformation. 3 Based on 1” thickness. 4 These numerical flame-spread and smoke-developed ratings are not intended to reflect hazards presented by this or any other material under actual fire conditions. 1 * Styrofoam™ Brand Cavitymate

Open the catalog to page 1

TESTING Applicable Standards DuPont™ Styrofoam™ Brand Cavitymate™ Plus Extruded Polystyrene (XPS) Foam Insulation meets ASTM C578 – Standard Specification for Rigid Cellular Polystyrene Thermal Insulation, which includes: • C272 – Standard Test Method for Water Absorption of Core Materials for Structural Sandwich Constructions • D2842 – Standard Test Method for Water Absorption of Rigid Cellular Plastics • C518 – Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus • D1621 – Standard Test Method for Compressive Properties of Rigid...

Open the catalog to page 2All Dupont Building and Construction catalogs and technical brochures

-

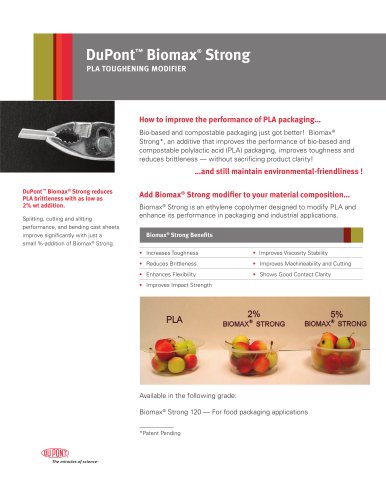

Biomax® Strong

2 Pages

-

NEW Corian® World

47 Pages

-

PLANTEX® COCOMAT

4 Pages