Catalog excerpts

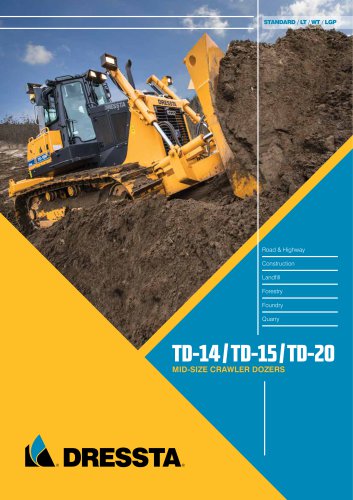

Road & Highway Construction Landfill Forestry Foundry Quarry TD-14 TD-15 TD-20 MID-SIZE CRAWLER DOZERS

Open the catalog to page 1

Engineered for productivity and precision When your business relies on equipment that is durable, productive and backed up by a global network – you can rely on Dressta. Over its 70+ year history, Dressta has developed a reputation for productive equipment tailored to the needs of its hardworking customers. Dressta’s mid-size dozers have the muscle and finesse to get the job done quickly and efficiently. Operator comfort, ease of serviceability and productivity are at the heart of their design, while outstanding power, agility and precision deliver the right performance at any job site....

Open the catalog to page 2

Designed for command and control Controllability equals productivity. Dressta mid-size dozers deliver precise and predictable control with outstanding pushing power. WORK YOUR WAY - BETTER BLADE CONTROL & FASTER OPERATING SPEEDS Dressta dozers put finesse at your fingertips, so that you get faster results, reach final grade in fewer passes, and move more material in less time. This adds up to greater efficiency, which translates to lower costs. A responsive electro-hydraulic, left hand joystick controls travel direction and steering while the right hand joystick gives control of the blade....

Open the catalog to page 4

PRODUCTIVE AND DEPENDABLE ENGINE Dressta’s mid-size dozers are powered by a range of turbocharged Cummins engines which feature a high-pressure common-rail fuel system to ensure efficient performance while supplying the power you need for maximum productivity at the job site. Thanks to the proven common-rail fuel system, this technology delivers a precise quantity of fuel at high pressure and increases fuel economy and performance, decreasing exhaust and noise emissions with consistent performance at every rpm. TD-14M EXTRA / TD-14R / TD-15R EXTRA Engine: Cummins QSB 6.7 Emission Standards:...

Open the catalog to page 5

Heavy duty design Dressta dozers are built with a one-piece mainframe for exceptional strength so you can get on with the toughest of jobs with confidence. The front section of the mainframe supports the radiator, engine, torque converter and transmission, while the rear section supports steering drive and the final drives. Working loads from the blade and rear mounted attachments are evenly distributed through the frame and undercarriage. The robust design includes a heavy-duty undercarriage, available in various options, to enhance performance through stability in different types of...

Open the catalog to page 6

TRACKS SHOES Track gauge Track length on ground Shoes, each side Shoe width

Open the catalog to page 7

Dressta operators will enjoy exceptional in-cab comfort from the performance of the air conditioning system to the location of the controls for optimal operator comfort. The FOPS and 2-post ROPS certified cab provides more space and is equipped with: • Large tinted side and rear sliding windows for cross ventilation and an enhanced view of both the blade and ripper equipment. • Air recirculation system. • Air conditioner / heater / pressurizer. • Noise reduction trim. • Deluxe air suspension seat including 6-way adjustment and arm rests. • Ergonomically designed joystick controls for...

Open the catalog to page 8

RESPONSIVE AND PREDICTABLE STEERING CONTROL TD14, TD15 and TD20 feature a steering drive that is controlled with the left-hand joystick. The joystick controls the transmission in high or low range as well as left or right gradual speed turns. Brakes for parking and downhill control are activated by a foot pedal, and are spring applied and hydraulically released. MAXIMUM VISIBILITY The cab provides clear view to the blade and ripper working areas and the entire job site, with a direct line of sight to the cutting edge, making it easy to follow the flow of material under the blade.

Open the catalog to page 9

Attachments enhance productivity and versatilityA great dozer can only deliver great results with the right attachments. Dressta’s robust blades and rippers are designed to power through even the toughest of material and are suited to a wide range of applications. BLADES The Semi-U Blade design combines the penetration ability of a straight blade with the increased capacity provided by short wings. It is ideal for applications like road and highway construction. The 6-way blade control system is designed for performance and final grade control. With its motion capabilities, these blades are...

Open the catalog to page 10

RIPPERS The single shank ripper option offers a standard shank with exceptional penetration, allowing full use of the remarkable drawbar pull of the machine. An adjustable parallelogram multishank ripper also offers outstanding penetration in various ground conditions and can be used with up to three shanks. Both the single and multi-shank rippers are equipped with best-inclass (largest diameter) pitching cylinders to change the angle of the attack of the ripper shank according to ripping conditions. Ripper (Standard)

Open the catalog to page 11

Servicing made easy Controlling servicing and maintenance costs is critical to achieving maximum lifetime value from your equipment. Keeping your Dressta dozer in top running condition requires less effort, thanks to ground-level access to the engine and all daily maintenance checkpoints. The modular power train layout means every major component can be serviced or replaced in the field in just a few hours. The cooling system features aluminium bar plates for improved heat transfer and reduced resistance to air flow. The modular design makes it easier to access for maintenance and regular...

Open the catalog to page 12

EASY ACCESS AUTOMATIC GREASING All service and maintenance points are clearly marked and easily accessible, with diagnostic points conveniently grouped together. Built-in reminders in the on-board monitoring system help to ensure that servicing is taken care of when needed. An optional automatic greasing system makes servicing even easier, helping to lower maintenance costs and improve machine productivity. This automatic system improves bearing life and reduces the need for repairs by delivering frequent and exact amounts of grease to each bearing.

Open the catalog to page 13All DRESSTA catalogs and technical brochures

-

TD-25_2023

24 Pages

-

TD-25

12 Pages

-

TD-8S TD-9S

24 Pages

-

NEW TD-25

12 Pages

-

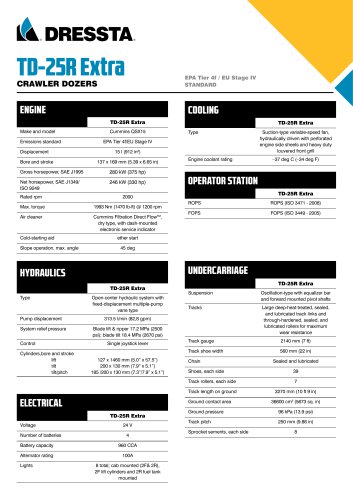

TD-25R Extra

6 Pages

-

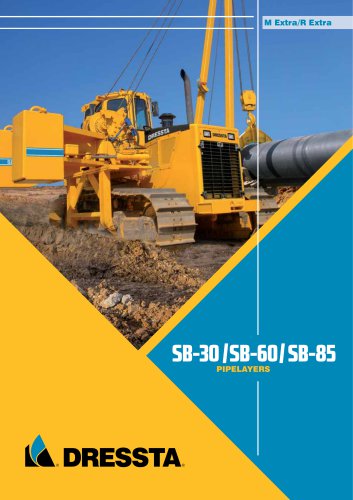

SB-30 SB-60 SB-85

20 Pages

-

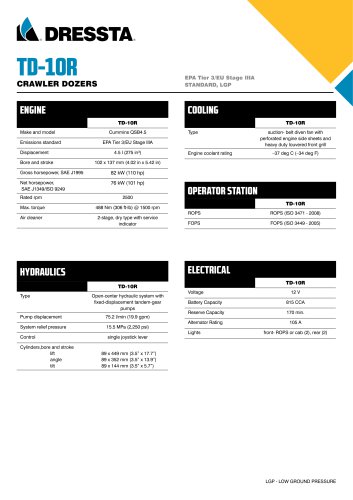

TD-10R

6 Pages

-

TD-40

6 Pages

-

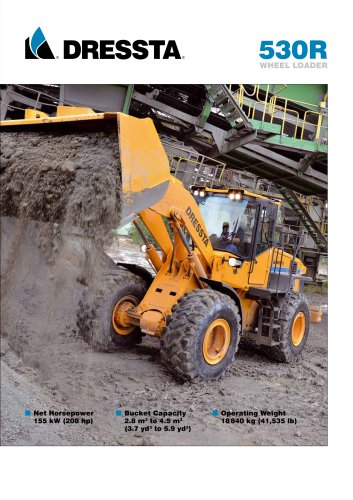

530R

8 Pages

Archived catalogs

-

TD-14 / TD-15 / TD-20

32 Pages

-

TD-8S / TD-9S

24 Pages