Catalog excerpts

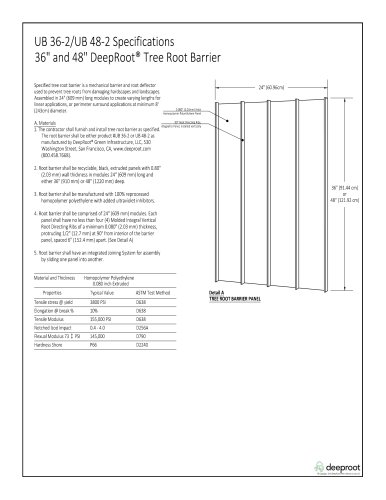

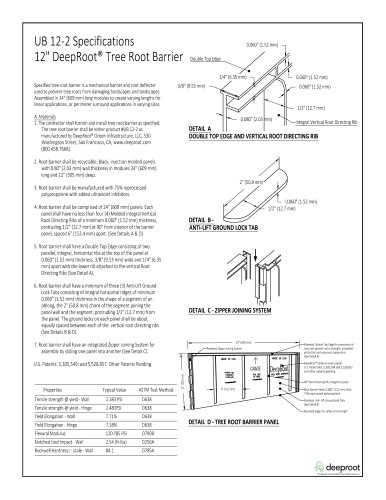

Specified tree root barrier is a mechanical barrier and root deflector used to prevent tree roots from damaging hardscapes and landscapes. Assembled in 24" (609 mm) long modules to create varying lengths for linear applications, or perimeter surround applications in varying sizes. A. Materials 1. The contractor shall furnish and install tree root barrier as specified. The tree root barrier shall be either product #UB 24-2 as manufactured by DeepRoot® Green Infrastructure, LLC, 530 Washington Street, San Francisco, CA, www.deeproot.com (800.458.7668). 2. Root barrier shall be recyclable, black, injection molded panels with 0.80" (2.03 mm) wall thickness in modules 24" (609 mm) long and 24" (609 mm) deep. 3. Root barrier shall be manufactured with 75% reprocessed polypropylene with added ultraviolet inhibitors. 4. Root barrier shall be comprised of 24" (60.96 cm) panels. Each panel shall have no less than four (4) Molded Integral Vertical Root Directing Ribs of a minimum 0.075" (1.90 mm) thickness, protruding 1/2" (12.7 mm) at 90° from interior of the barrier panel, spaced 6" (152.4 mm) apart. (See Details A & D) 5. Root barrier shall have a Double Top Edge consisting of two parallel, integral, horizontal ribs at the top of the panel at 0.060" (1.52 mm) thickness, 3/8" (9.53 mm) wide and 1/4" (6.35 mm) apart with the lower rib attached to the vertical Root Directing Ribs (See Detail A). DOUBLE TOP EDGE AND VERTICAL ROOT DIRECTING RIB 0.075" (1.90 mm) 1/2" (12.7 mm) DETAIL B-ANTI-LIFT GROUND LOCK TAB 6. Root barrier shall have a minimum of twelve (12) Anti-Lift Ground Lock Tabs consisting of integral horizontal ridges of minimum 0.075" (1.90 mm) thickness in the shape of a segment of an oblong, the 2" (50.8 mm) chord of the segment joining the panel wall and the segment, protruding 3/8" (9.53 mm) from the panel. The twelve ground locks on each panel shall be about equally spaced between each of the vertical root directing ribs (Four (4) between each set of ribs, see Details B & D). 7. Root barrier shall have an integrated Zipper Joining System for assembly by sliding one panel into another (See Detail C). U.S. Patents: 5,305,549; and 5,528,857. Other Patents Pending. Properties Typical Value ASTM Test Method Tensile strength @ yield - Wall 2.354 PSI D638 Tensile strength @ yield - Hinge 2.846 PSI D638 Yield Elongation - Hinge 7.01% D638 Notched Izod Impact-Wall 3.84 (ft-lbs) D256A Rockwell Hardness r. scale - Wall 84.4 D785A DETAIL C - ZIPPER JOINING SYSTEM

Open the catalog to page 1All DeepRoot Urban Solutions catalogs and technical brochures

-

UB 36-2/UB 48-2

1 Pages

-

UB 18-2 Specifications

1 Pages

-

UB 12-2 Specifications

1 Pages

-

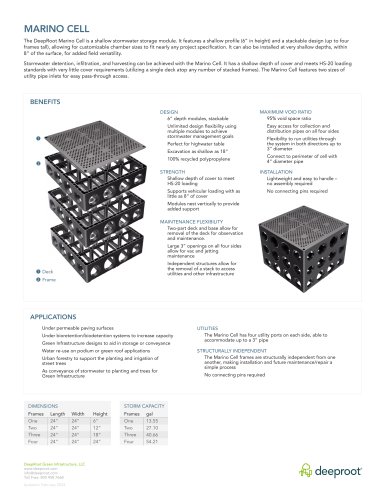

MARINO CELL

1 Pages