Website:

DALIFORM GROUP srl

Website:

DALIFORM GROUP srl

Group: Daliform

Catalog excerpts

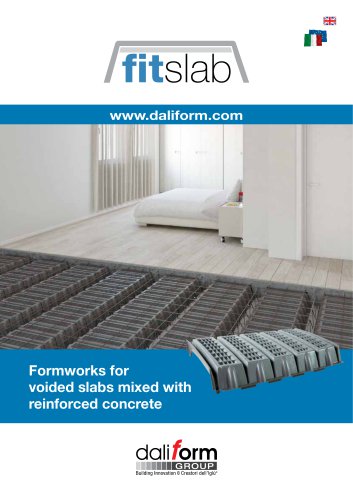

Disposable formwork for two-way voided slabs in reinforced concrete cast on site Building Innovation 6 Creatori dell’lglu’

Open the catalog to page 1

SWITCHBOARD Telephone Fax FOREIGN COMMERCIAL SECRETARY OFFICE Telephone Fax e-mail TECHNICAL SECRETARY OFFICE Telephone Fax e-mail

Open the catalog to page 2

17-boot beton U-Boot Beton® is a recycled polypropylene formwork that was designed to create lightened slabs and rafts. The use of U-Boot Beton® formwork makes it possible to create mushroom pillars, with the possibility to have the mushroom in the thickness of the slab. Thanks to the conic elevator foot, immerging the U-Boot Beton® formworks in the concrete casting will create a gridwork of mutually perpendicular beams closed from the bottom and the top by a flat plate that is created with a single casting; this results in considerable reduction in the use of concrete and steel. U-Boot...

Open the catalog to page 3

System optimised with U-Boot Beton 11 Increased number of floors Possibility to gain floors at the same building height (towers) and building volume. 5 OPTIMISATION OF THE SECTION OF PILLARS REDUCTION IN THE NUMBER OF PILLARS Wider bays. Facilitated use reallocation. 2 LARGE SPAN AND GREAT ARCHITECTURAL FREEDOM Larger spaces. 3 REDUCED SLAB THICKNESS Thinner slabs but with equal loads and clearances, or bigger clearances with an equal thickness. 6 REDUCTION IN THE OVERALL LOAD OF THE STRUCTURE WEIGHING ON THE PILLARS AND THE FOUNDATION 7 LESS DEEP FOUNDATION EXCAVATION Lower costs for...

Open the catalog to page 4

Real advantages We are incorrectly led to estimate the advantage of a slab lightened with U-Boot Beton® limiting it to a mere comparison between savings in concrete and the cost of the formwork on the level of the slabs only. In this way however, as the analysis is immediate and intuitive, it does not account for the various economic, practical and operational advantages provided with U-Boot Beton® for the entire structure: less use of iron in the slabs, pillars and foundation up to a total of 15% (also in the case of variants); less concrete is used not only for the slabs but also for the...

Open the catalog to page 5

Applications U-Boot Beton® is used in all applications that require a structural plate together with the need to use less concrete and therefore for a lighter structure. U-Boot Beton® is the ideal solution for creating slabs with a large span and/or great load-bearing capacity: it is particularly suited for structures that require considerable open spaces, such as executive, commercial and industrial buildings as well as public, civil and residential structures. It makes it possible to more irregularly distribute the pillars, as beams do not need to be created. In the case of yards that are...

Open the catalog to page 6

Photo gallery Tower building - Arch. Paolo Portoghesi Automobile museum of Turin Project Vulcano Buono- Arch. Renzo Piano Hospital Borgo Trento Headquarters of the ITC Lab Kilometro Rosso Arch. Richard Meier

Open the catalog to page 7

Range - parameter and consumption table *Volume related to one possible combination “UP + DOWN”. ** U-Boot® Beton H 24 DOWN with feet >8 cm. *Volume related to one possible combination “UP + DOWN”.

Open the catalog to page 8

* Composed of two single elements Retirement home Building forindustrial use 8

Open the catalog to page 9

* Composed of two single elements Project Treviso Maggiore - Arch. Mario Botta Building for residential use 13

Open the catalog to page 10

Characteristics of a U-Boot Beton® slab and comparison with a full slab Square mesh clearance * Slab inertia calculated on 16 cm rib.

Open the catalog to page 11

Beams in the slab thickness - The spacer joint The U-Boot Beton® lightened plate slab has a perpendicular beam gridwork of the same thickness as the slab that transfers all stresses directly to the pillars around which it will suffice to leave a full zone of variable dimensions based on the shearing forces. Beam dimensioning and their perfect implementation on site depends on the orderly and precise layout of the lightening elements during installation but especially during casting. Correct positioning of the U-Boot Beton® is guaranteed by an effective rigid spacer joint with graduated...

Open the catalog to page 12

Installation REINFORCEMENTS LOWER REINFORCEMENT SIDE SHUTTERING TRADITIONAL SHUTTERING IN WOOD OR METAL REINFORCEMENTS SIDE SHUTTERING 1 The entire surface of the slab to be cast on site is shuttered with wood 2 The U-Boot Beton® formworks are positioned using the lateral deckings (or similar systems), then the lower reinforconcrete bars are positioned in two mutually perpendicular directions according to the design and the lattice for the upper reinforconcrete is arranged. spacers joints to place them at the desired centre distance that will determine the beam width. Thanks to the conic...

Open the catalog to page 13

Application examples: rafts Among the various foundation types, rafts are one of the most well known. They are used above all in ground conditions with little bearing capacity, or with poor quality soil, large thicknesses must be used which increases the construction cost. Thanks to the use of U-Boot Beton® lightened rafts can be created with the same performance but at a considerably lower cost. Once drown in the concrete casting, U-Boot Beton® forms the structure just like two full slabs, with a variable thickness, connected by a perpendicular beam gridwork to form a bidirectional static...

Open the catalog to page 14

U-Boot Beton®: excellence The quality of the used mixture, the innovative shape, the thicknesses and dimensions of the product, the fire safety and strict working techniques make it a product of excellence. U-Boot Beton®, is not subject to deformations, either during or after the casting, either due to the weight of the concrete or the dynamic effect connected to the work operations: it is able to support before casting the workers and fresh concrete, the pressure created during the compression and vibration of the casting, the weight of people, reinforconcretes and equipment guaranteeing...

Open the catalog to page 15

Environmental compatibility Daliform Group has again demonstrated to be extremely precise with regard to respecting health and the environment having been the first to obtain Environmental Compatibility Certification (CCA) for its products. This certificate is very important for U-Boot Beton® because it demonstrates: the lack of dangerous substances in its composition (even if recycled materials are used); the lack of emissivity of toxic substances during the various phases of the product's life and operating cycle, which benefits the health of the intermediate users (production and...

Open the catalog to page 16All DALIFORM GROUP srl catalogs and technical brochures

-

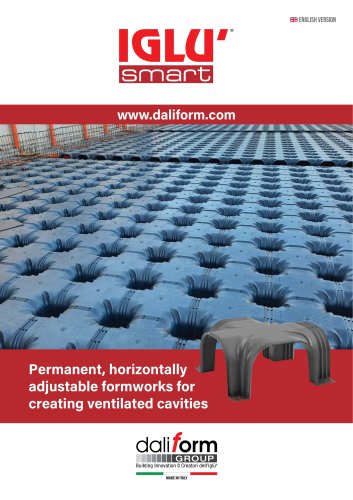

Iglu Smart

8 Pages

-

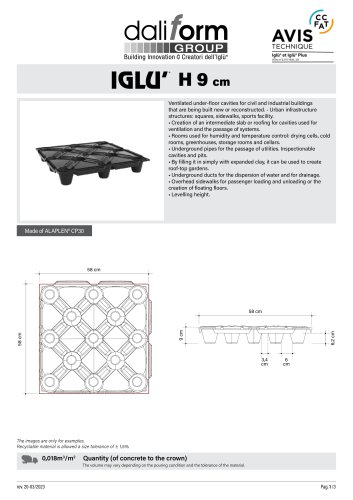

H09-iglu-en

3 Pages

-

H08-iglu-en

3 Pages

-

H06-iglu-en

3 Pages

-

H05-iglu-en

3 Pages

-

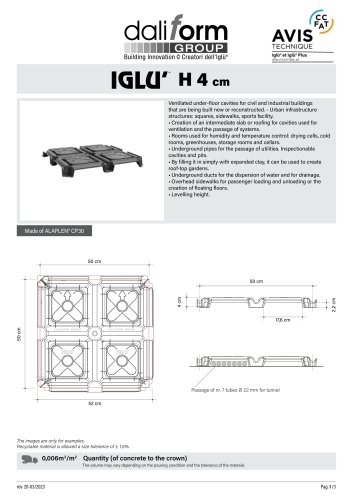

H04-iglu-en

3 Pages

-

U BOOT-SILENCE

8 Pages

-

GREENPARK_EN

8 Pages

-

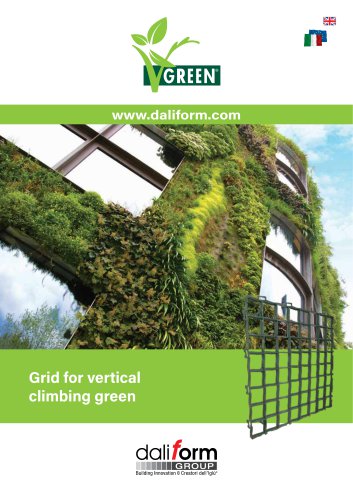

V-Green_EN

4 Pages

-

IGLU-Smart-EN

4 Pages

-

COFFRARGILE

12 Pages

-

IGLU'® VENTILATED ROOF

8 Pages

-

IGLU'®

24 Pages

-

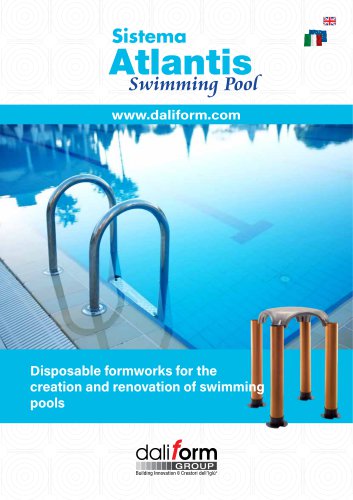

ATLANTIS

16 Pages

-

ISO IGLU'

8 Pages

-

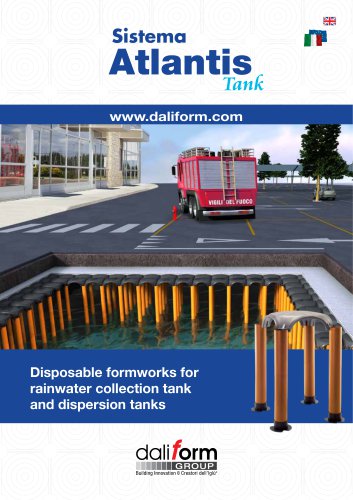

ATLANTIS TANK

20 Pages

-

PARATOPRATICO®

16 Pages

-

E.C.O. by PRATOPRATICO®

8 Pages

-

V-GREEN®

4 Pages

-

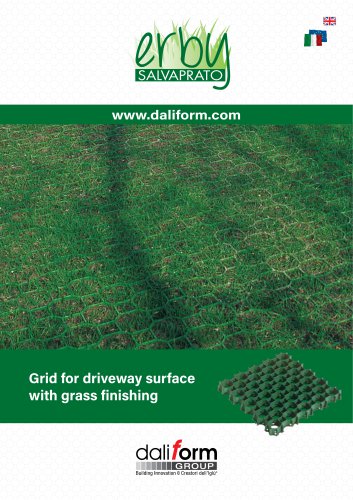

ERBY SALVAPRATO

4 Pages

-

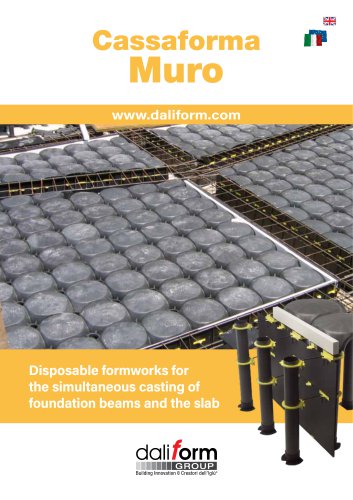

Cassaforma Muro

10 Pages

-

ATLANTIS SWIMMING POOL

12 Pages

-

Company Profile

12 Pages

-

EASY RIDE

4 Pages

-

EASY PARK®

8 Pages

-

U-BOOT SILENCE

8 Pages

-

U-BAHN® BETON

10 Pages

-

IGLU'® GREEN ROOF

12 Pages

-

FIT SLAB

10 Pages

-

Conrete accessories

20 Pages

Archived catalogs

-

EOLO

9 Pages