Website:

DALIFORM GROUP srl

Website:

DALIFORM GROUP srl

Group: Daliform

Catalog excerpts

Disposable formworks dali/brm GROUP Building Innovation 6 Creatori dell’lglu'

Open the catalog to page 1

Ecological, Environmentally FriendlyCertifications SWITCHBOARD Telephone Fax FOREIGN COMMERCIAL SECRETARY OFFICE Telephone Fax e-mail TECHNICAL SECRETARY OFFICE Telephone Fax e-mail

Open the catalog to page 2

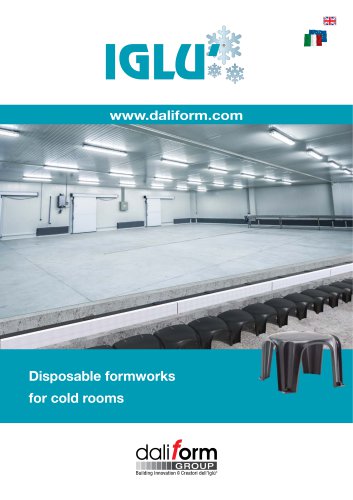

Cold rooms are facilities in which a constant temperature is maintained in order to conserve foods. They are now used everywhere in the food industry and are divided principally into low-temperature cold rooms, called negative cold rooms (in which the temperature can vary from -4° C to -30° C), and medium-temperature, or positive cold rooms (in which the temperature can vary from 0° C to + 4° C). A problem that has always been associated with the construction of negative cold rooms negative is the likelihood that the cold will eventually propagate through the structures and reach the...

Open the catalog to page 3

Advantages • Prevents deformation and lifting of floor (frost heave). • High resistance to distributed and concentrated loads. • Effective ventilation in all directions. • Elimination of freezing air. • Up to 80% reduction in man hours needed to install the ventilated cavity compared to conventional systems. • Drastic reduction in the consumption of reinforced concrete due to the domed shape which enables maximum resistance with minimum thickness. • Adaptability to "out of square” spaces, as the modules can be cut without underpinning. • Ease of positioning due to lightness and simple...

Open the catalog to page 4

Applications Iglu’® is the most secure and economical constructive solution for installing ventilated cavities under both positive and negative cold rooms. It guarantees that the temperature of the cavity remains above zero by removing the moisture present in the substrate. This prevents the freezing and deformation of the foundation sediments (the lean concrete/soil assembly) which pushes the laying surface upwards and causes the floor to crack (a process known as frost heave). The use of Iglu’® for the construction of industrial flooring for cold rooms was established in the 2014 LGPCF...

Open the catalog to page 5

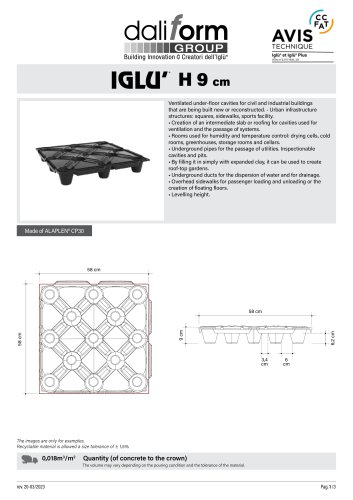

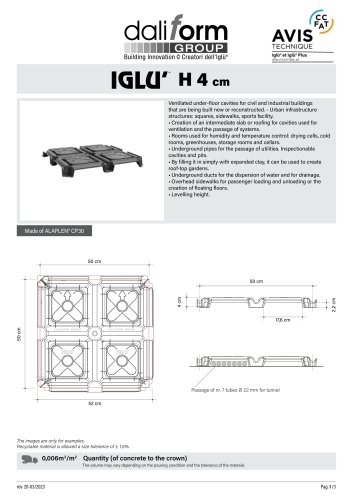

The material is waterproof and can therefore be stored outside. * Recyclable material is allowed a size tolerance of ± 1,5%. ** The volume may vary depending on the pouring condition and the tolerance of the material. Depending on the different heights, the shape of the shuttering will differ from what is shown in the drawing. Hypothesis of ULS calculation based on Iglu® system h27 cm Supposing a distributed load, the table shows minimum slab thickness, reinforcement and pressure on soil depending on lean concrete thickness. Pressures at the bottom of the structure The table expresses,...

Open the catalog to page 6

Case Study: Negative Cold Room with Iglu’® In the case study presented here, it was necessary to create a negative cold room with an under-floor cavity that would allow good air circulation so as to prevent the moisture from forming condensation that would then turn into ice. The design that was developed for achieving this objective involved the use of Iglu’® h 27 cm modules. Due to the domed shape and supporting feet of the modules,Iglu’® guaranteed a higher capacity with respect to the design load, whether distributed or concentrated, and assured that the performance required of the...

Open the catalog to page 7

Photo gallery Negative cold room - Chatillon En Vandellais (France) Negative cold room - France Negative cold room - Italy Negative cold room - Italy Negative cold room - Boisseron (France) Negative cold room - Ed Lens (France)

Open the catalog to page 8

Modalità di esecuzione del vespaio aerato 1 Construct the lateral foundation beams, leaving openings for the ventilation of the under-floor cavity according to the design. 2 Lay the interlocking male/female formworks from left to right and top to bottom, making sure that the arrow marked on the formwork itself is facing upward. 5 Lay the electro-welded mesh on top of the formwork. Cast the concrete from the centre of the arch, allowing it to flow inside the Iglu’® legs to provide a carrier substrate for the subsequent layers and for the floor which will bear the design loads. It is imperative...

Open the catalog to page 9

Fig. 1 - Dry positioning of the first formwork, the arrow is facing the foundation curb. Fig. 2 - Dry positioning sequence of the modules by row. 1 Position the first element to the upper left with respect to the work surface, making sure that the arrow is pointing up (Fig. 1). 2 Unite the elements in sequence, by horizontal row, proceeding from the left towards the right and from the top downwards (following the direction normally used for writing), as shown graphically on the crown of each unit (Fig. 2). 3 To unite the units in sequence, be careful to perfectly link the “male-female”...

Open the catalog to page 10

L-Plast is used for new constructions to create the slab and foundation beams with a single concrete casting; when restructuring is used to easily create reinforcement curbs for existing foundations. Furthermore, L-Plast is ideal for creating air ducts in general, such as for cold rooms, for example (if forced ventilation is necessary) or in geothermal applications where air must be blown into the under-floor cavity. When restructuring, when the existing walls must be reinforced or when an underpinning must be created, L-Plast is a useful work tool that helps creating a new slab or...

Open the catalog to page 11

Iglù®: excellence The quality of the “compound”, the particular shape, the thicknesses, the dimension of the product and the work techniques make Iglù® a product of excellence. Designed for solving problems with Radon and humidity in modern, economic terms, also respecting the environment, Iglù® will not undergo, either during and after the casting, dangerous deformations due not only to the weight of the concrete but also to the dynamic effect of the work operations, such as: the load of the fresh concrete, pressure from casting compression and vibration, the weight of people and...

Open the catalog to page 12All DALIFORM GROUP srl catalogs and technical brochures

-

H09-iglu-en

3 Pages

-

H08-iglu-en

3 Pages

-

H06-iglu-en

3 Pages

-

H05-iglu-en

3 Pages

-

H04-iglu-en

3 Pages

-

U BOOT-SILENCE

8 Pages

-

GREENPARK_EN

8 Pages

-

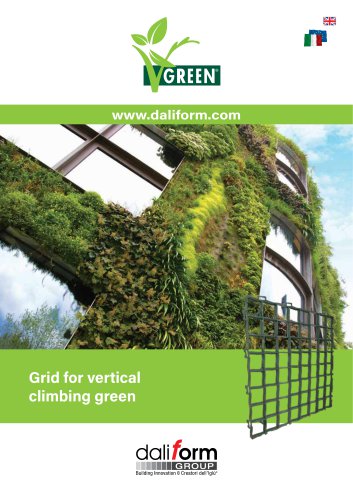

V-Green_EN

4 Pages

-

IGLU-Smart-EN

4 Pages

-

COFFRARGILE

12 Pages

-

IGLU'® VENTILATED ROOF

8 Pages

-

IGLU'®

24 Pages

-

ATLANTIS

16 Pages

-

ISO IGLU'

8 Pages

-

ATLANTIS TANK

20 Pages

-

PARATOPRATICO®

16 Pages

-

E.C.O. by PRATOPRATICO®

8 Pages

-

V-GREEN®

4 Pages

-

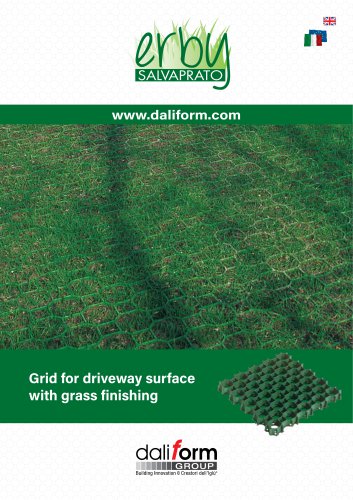

ERBY SALVAPRATO

4 Pages

-

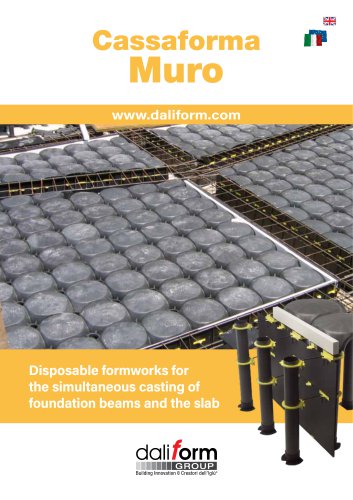

Cassaforma Muro

10 Pages

-

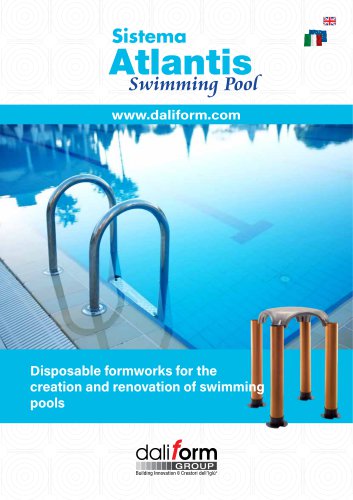

ATLANTIS SWIMMING POOL

12 Pages

-

Company Profile

12 Pages

-

EASY RIDE

4 Pages

-

EASY PARK®

8 Pages

-

U-BOOT SILENCE

8 Pages

-

U-BAHN® BETON

10 Pages

-

IGLU'® GREEN ROOF

12 Pages

-

FIT SLAB

10 Pages

-

U-BOOT® BETON

21 Pages

-

Conrete accessories

20 Pages

Archived catalogs

-

EOLO

9 Pages