Catalog excerpts

TECHNICAL INFORMATION

Open the catalog to page 1

CONTENTS STONEPANEL® TYPES STONEPANEL SKY® INSTALLATION GUIDE STONEPANEL® INSTALLATION STONEPANEL SKY® INSTALLATION ENVIRONMENTAL STATEMENT COMPARISON WITH OTHER PANELS STONEPANEL® MODELS SPECIAL PIECES

Open the catalog to page 2

NATURAL STONE PANELS TECHNICAL INFORMATION STONEPANEL® TYPES STONEPANEL SKY® Prefabricated STONEPANEL® panels are made of natural stone attached to a concrete base reinforced with fiberglass mesh to ensure the stones remain attached. STONEPANEL SKY® is the most secure and effective solution for installing stone panels at higher levels. These panels are recommended for installation on surfaces higher than two meters. This model features a stainless steel attachment loop, which ensures the most secure attachment of the STONEPANEL® on a vertical face. NATURAL STONE PANELS

Open the catalog to page 3

INSTALLATION GUIDE STONEPANEL® 1. he same guidelines followed for installation of any other T type of natural stone panels should be followed. In other words, make sure each piece is level and plumb. T 2. he surface to be covered should be measured accurately and the panels purchased should cover at least 5% extra surface area to account for losses caused by cutting. 3. or remodeling or rebuilding projects, any existing surfaF ce coverings should first be removed. For painted walls, the paint should be removed by scraping or grinding. Any cracks or holes should be filled with cement grout....

Open the catalog to page 4

NATURAL STONE PANELS TECHNICAL INFORMATION 4. serrated trowel should be used to apply the adheA sive in a double 6-7 mm layer, covering both the back of the STONEPANEL® panel and the wall surface. It is important to make sure that the adhesive used can support the weight of the piece (6-12 kg depending on model). 5. he lowest row should be installed first, with the individual T STONEPANEL® panels interlocking. In the second row, the location of the joints should be alternated with respect to the first row in order to make the joints less visible. This alternation of pieces should continue...

Open the catalog to page 5

7. rim the panels using a radial saw or a water jet cutter T to accommodate any elements projecting from the wall surface. 8. Walls with corners. a. n the case of walls with corners, always begin instaI llation at the corners using a long piece with a straight end, then use a short piece with a straight end to start the second row, alternating these lengths after that. b. nother option is to use the solid corner pieces from A the STONEPANEL® product line. These are manufactured with a built-in corner ready to be installed. NATURAL STONE PANELS

Open the catalog to page 6

NATURAL STONE PANELS TECHNICAL INFORMATION INSTALLATION GUIDE STONEPANEL SKY® STONEPANEL SKY® panels have a stainless steel attachment loop that allows them to be screwed to the wall using our special anchoring adapter or a piece of perforated metal strip. 1. tart with the anchoring adapter that will allow the S natural stone panel to be attached to the wall (recommended width 12-17 mm). B 2. end the anchoring adapter in half so that two of the holes are aligned and the screw can pass through both. 3. nsert the anchoring adapter through the panel’s atI tachment loop so it faces upwards for...

Open the catalog to page 7

5. rill a hole in the wall for inserting a nylon screw anD chor. This hole must be aligned with the holes that will be used in the anchoring adapter. 6. inally, insert the screw through the adapter and into the F nylon screw anchor, then tighten. The STONEPANEL SKY® panel will be securely attached. 7. ollow the same procedure with the rest of the panels in F the row and with the rest of the rows, so that the anchoring adapters are completely covered by the adhesive and do not interfere with installation of the panels covering them. To prevent variations caused by an uneven wall surface, it...

Open the catalog to page 8

NATURAL STONE PANELS TECHNICAL INFORMATION ENVIRONMENTAL IMPACT Comparative analysis of STONEPANEL® and other sur- facing products' environmental impact. GRANITE FACING STEEL SHEETS Steel sheet TEXTURED PANELS Fiber cement STONEPANEL NATURAL STONE PANELS

Open the catalog to page 9

COMPARISON WITH RESIN-BASED PANELS RUSTIC PANEL ABSENCE OF BREAKAGE DURING TRANSPORT The mesh is not in contact with the entire panel surface. The purpose of the fiberglass mesh is to constrain expansion of the concrete even if the concrete suffers impacts during transport. The panel does not have safety anchoring. PROBLEMS: during transport the mesh does not prevent stones from falling off in the event of breakage. PROBLEMS: Risk of panel falling from the facade in the event that the adhesive fails. Should not be installed at heights above 2m. PREVENTION OF FALLING STONE PANELS AFTER...

Open the catalog to page 10

NATURAL STONE PANELS TECHNICAL INFORMATION LIGHT BLOCK The purpose of the fiberglass mesh is to constrain expansion of the concrete even if the concrete suffers impacts during transport. Does not have reinforcement mesh, so breakage or falling stones are possible during transport. Has a stainless steel anchoring loop embedded in the base. If the installation adhesive fails the panel will remain anchored until it can be replaced. The panel does not have safety anchoring. The stones are attached to the concrete base during manufacture under optimal controlled conditions. Perfect adhesion...

Open the catalog to page 11

STONEPANEL" MODELS STONEPANEL® Multicolor Sandstone STONEPANEL® Weathered Nordic STONEPANEL® Black Sandstone STONEPANEL® Multicolor STONEPANEL® Nile STONEPANEL® Nordic STONEPANEL® Black Blocks STONEPANEL® Weathered Rustic NATURAL STONE PANELS

Open the catalog to page 12

NATURAL STONE PANELS TECHNICAL INFORMATION STONEPANEL® - SPECIAL PIECES Solid corner L-shaped natural stone panel made for installation on corners. The corner is built-in so installation is quick and easy. Solid corner for windows L-shaped natural stone panel, with long end staggered and short end straight. Designed to accommodate junctions with windows. Straight end These differ from the standard STONEPANEL® panels because one of the two ends is straight. These have been created for walls without corners. Both short and long panels with one straight end are available. Double end Natural...

Open the catalog to page 13All CUPA STONE catalogs and technical brochures

-

INFERCOA

8 Pages

-

STONEPANEL®

16 Pages

-

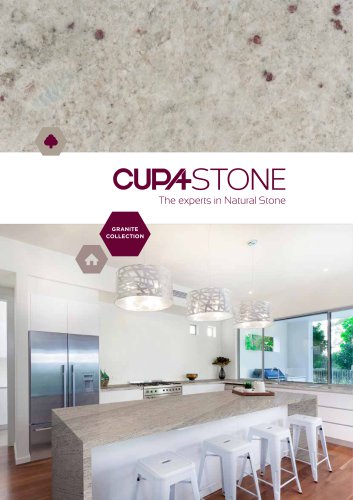

Granites

11 Pages

-

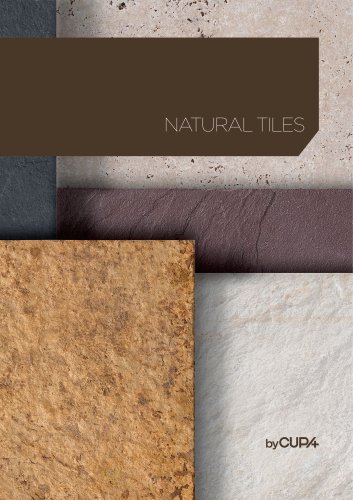

Natural Tiles

65 Pages

-

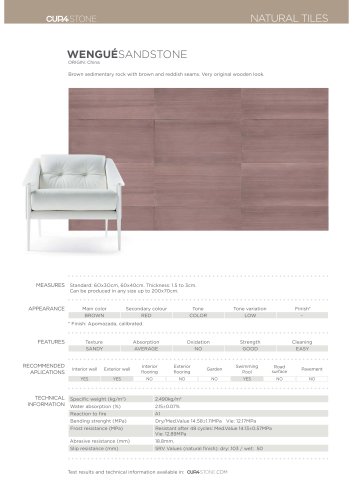

WENGUE-SANDSTONE

2 Pages

-

CARIOCA-BRONZE-QUARTZITE

2 Pages

-

BLUE-PEARL-GRANITE

2 Pages

Archived catalogs

-

trip

2 Pages

-

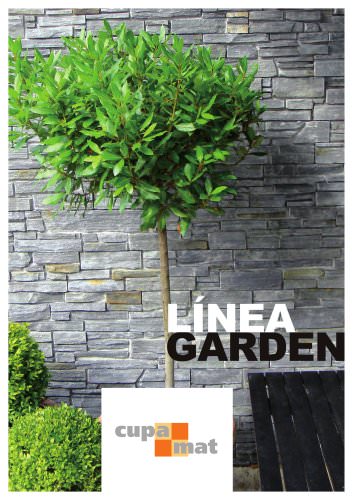

Garden Line

2 Pages