Website:

INTERAL CUHADAROGLU METAL SANAYI

Website:

INTERAL CUHADAROGLU METAL SANAYI

Catalog excerpts

Since 1954 ... C-ALU is a Trademark of CUHADAROGI-U Holding

Open the catalog to page 1

mmumrmmw m wr m ■ u. minim mimj mramufiyy! -, tiiNMinnimii-* bi ■ * m ■ r vgf flip |B iff!' iiiiimiurmiii msems i inVmmimn'i i tm.vmv.Vm f Vi'rVnVmVi H VmiViVi'mm rrntnirirrVVrrir . f i nffinitim r r tj pyrnmYift'iViiii iiYm'ii it t imViii eS MMtimnitmril Jt iVi'iViVi pruViM ■ uiiVimitMi i*M 11 pniViViViViV»V( [ihn t m ini i f m r ■niiViVtVll iVitVi

Open the catalog to page 2

APPROVED QUALITY IN THE ALUMINIUM PROFILE is a leading aluminium extrusion and aluminium profile systems company and a member of ÇUHADARO⁄LU HOLD‹NG A.fi. which vas founded in 1954. The production processes are carried out according to international quality standards suchs as ISO 9001, QUALANOD, QUALICOAT, GOST and Turkish Standards (TSE) accomplishes its production activities in its 70.000 square - meters integrated factory that contains casting line, die shop, extrusion lines, surface treatments units, machining shops, assembling lines and ResearchDevelopment Center. supplies its aluminium...

Open the catalog to page 3

With an experience over a half century, is an integrated enterprise in which all processes are performed with the aluminium billet casting, extrusion lines, molding workshop, surface treatment units, mechanical processing and installation workshops in its factory, located on an area of total 70.000 square meters, in Istanbul. extrudes all of its aluminium products from primary aluminum alloys whose qualities are worldwide approved and certified. performs all operations related to the aluminium billet casting and extrusion process according to the procedures of BS EN ISO 9001:2008....

Open the catalog to page 5

Vertical Casting Line / Senkrechte Giessanlage

Open the catalog to page 6

VERTICAL CASTING LINE We are newly producing primary aluminium billets with a diameter range of 6, 7 and 10 inches for length maximum 7,2 meters. Our high-tech brand new controlling equipments grants us to produce high sensibility billets in according to control chemical composition before and after casting. Our plant achieves highest billet casting quality, with using Wagstaff degassing system which is integrated electromagnetic liquid aluminium mixing technology in order to ensure the lowest hydrogen and lowest inclusion ratio in the aluminium structure. SENKRECHTE GIESSANLAGE Neulich...

Open the catalog to page 7

Mold Production / Werkzeugbau

Open the catalog to page 8

DIE PRODUCTION LINE Being aware of the fact that high product quality and high productivity can only be provided, based on an excellent die develops, designs and produces aluminum design, extrusion dies within its own die shop. makes use of state-of-art machinery and equipment that are operated through CAD/CAM (3-Dimensional Design and Operation System) Technology, which enables the technical properties of each product to be reproduced. The die designs are transferred to the CNC Die-Processing Center via computer system. Thanks to the high-precision bench-machines, it is possible to produce...

Open the catalog to page 9

Extrusion Lines / Strangpresslinien

Open the catalog to page 10

We are realizing our profile manufacturing with 3 extrusion presses. • 1650 Mtons Power: Aluminium Billet Diameter 152 mm (entering size) • 1800 Mtons Power: Aluminium Billet Diameter 178 mm (entering size) • 4000 Mtons Power: Aluminium Billet Diameter 254 mm (entering size) AI_LJ has an annual production capacity of 20.000 tons aluminium extruded sections by means of its 1650-MT, 1800-MT, 4000-MT aluminium extrusion presses. Depending on the geometrical shape of the profiles; we can produce aluminium profiles between 0,4 -...

Open the catalog to page 11

Vertical Anodizing Line / Senkrechte Eloxalanlage

Open the catalog to page 12

SURFACE TREATMENTS UNIT applies mechanical surface pre-treatments, anodizing, and electrostatic powder-coating are applied on aluminium profiles. The Surface Treatments Facilities of are at the leading position in its sector with special pre-treatments, effects, and color alternatives it applies on aluminium surfaces. In the Unit for Mechanical Surface Pre-treatments -besides all kinds of mechanical polishing operations such as wirebrushing, satinizing, etc.- the desired surface effects are provided through etching process in the chemical etching bathes. We are proud to expose, that we have...

Open the catalog to page 13

Machining Process / Mechanische Bearbeitung

Open the catalog to page 14

MECHANICAL PROCESS LINE ’s Machining Shops carry out various operations including both perpandicular and angular precise cutting, drilling, countersinking, milling, bending, punching, bending, and assembling as well as production for special industries (airconditioning cabin production for metro systems, bank ATMs, framings, etc). MECHANISCHE BEHANDLUNGEN In den mechanischen Bearbeitungswerkstätten von werden alle mechanische Behandlungen einschließlich gerade und winklige Feinschnitte, Bohrung, Versenkung, Fräsung, Durchbiegung, Stanzung, und Montage durchgefüh

Open the catalog to page 15

Aluminium has been our passion for oven 56 years. Our main products are; Aluminium Billet: 6XXX serial alloy billets are available from our own high-tech brand new vertical casting line. Aluminium Exturision Profile: We mainly use; EN-AW 3003, EN AW 3004, EN AW 6060, EN AW 6063 EN AW 6082 aluminium alloys for production of aluminium extrusion profiles End-Use Applications of our Aluminium Profiles; • Hydraulic Gear Pumps Bodies • Pneumatic Cylinder Bodies • Photovoltaic Systems • Health Sector Equipment • Automotive Sector • Machinery Sector • Caravan Sector • Cooling Sector • Aviation...

Open the catalog to page 17

CERTIFICATES UNSERE ZERTIFIKATE

Open the catalog to page 18

PRODUCIBILTY GRAPH DIMENSIONS OF THE EXTRUDED ITEMS Maximum width of the section Maximum square of the section Maximum diameter of tubular section Maximum dimension of plate section Maximum weight per meter of the section : 65 kg/m P.S.: These dimensional limits are just for indication. Specific drawings can be evaluated for the producibilty, individually.

Open the catalog to page 19

YOUR BURDEN with Headquarter Hürriyet Mah. Cemil Bengü Cad. No.41 34403 Ka¤›thane - ‹stanbul / Turkey Phone + 90 212 224 20 20 (pbx) Phax + 90 212 224 20 40 Factory Yakuplu Köyü Yolu 34900 Büyükçekmece - ‹stanbul / Turkey Phone + 90 212 875 35 80 (pbx) Phax + 90 212 875 11 08 www.c-alu.com •

Open the catalog to page 20All INTERAL CUHADAROGLU METAL SANAYI catalogs and technical brochures

-

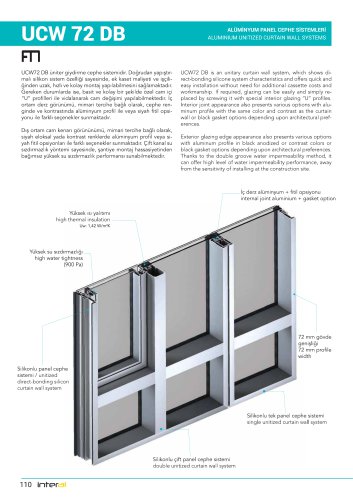

UCW 72 DB

2 Pages

-

IZO KE 50

2 Pages

-

UCW 72 CS

2 Pages

-

SKY 50 - 60 - 70

2 Pages

-

DS 50 VF

2 Pages

-

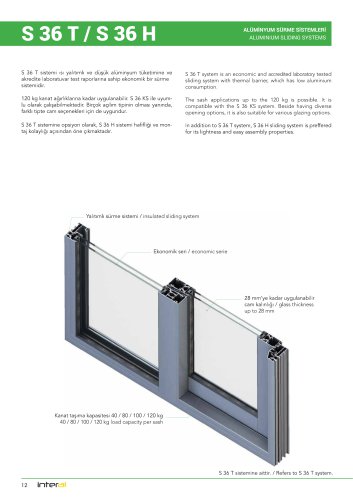

S 36 T / S 36 H

2 Pages

-

Security systems

6 Pages

-

Interwall

34 Pages

-

Product catalogue

31 Pages