Catalog excerpts

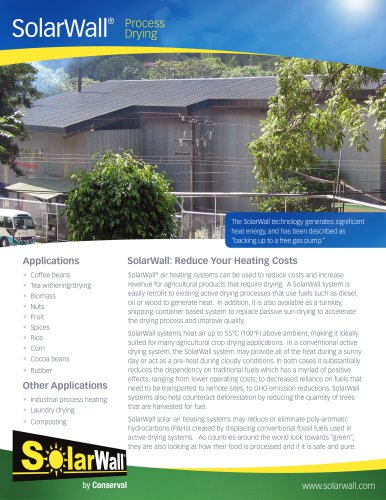

Process Drying The SolarWall technology generates significant heat energy, and has been described as “backing up to a free gas pump.” SolarWall: Reduce Your Heating Costs •• Coffee beans •• Tea withering/drying •• Biomass •• Nuts •• Fruit •• Spices •• Rice •• Corn •• Cocoa beans SolarWall® air heating systems can be used to reduce costs and increase revenue for agricultural products that require drying. A SolarWall system is easily retrofit to existing active drying processes that use fuels such as diesel, oil or wood to generate heat. In addition, it is also available as a turnkey, shipping-container based system to replace passive sun-drying to accelerate the drying process and improve quality. Other Applications •• Industrial process heating •• Laundry drying SolarWall systems heat air up to 55°C (100°F) above ambient, making it ideally suited for many agricultural crop drying applications. In a conventional active drying system, the SolarWall system may provide all of the heat during a sunny day or act as a pre-heat during cloudy conditions. In both cases it substantially reduces the dependency on traditional fuels which has a myriad of positive effects, ranging from lower operating costs, to decreased reliance on fuels that need to be transported to remote sites, to GHG emission reductions. SolarWall systems also help counteract deforestation by reducing the quantity of trees that are harvested for fuel. SolarWall solar air heating systems may reduce or eliminate poly-aromatic hydrocarbons (PAHs) created by displacing conventional fossil fuels used in active drying systems. As countries around the world look towards “green”, they are also looking at how their food is processed and if it is safe and pure.

Open the catalog to page 1

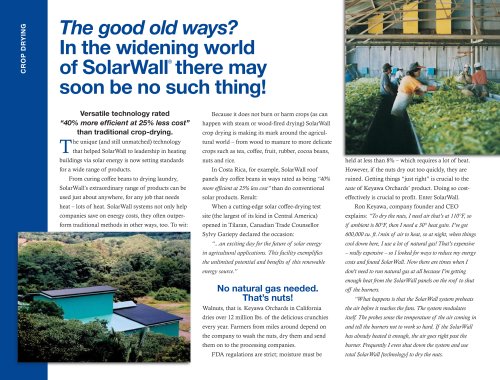

Process Drying No natural gas needed. That’s nuts! Walnuts, that is. Keyawa Orchards in California dries over 12 million lbs. of the delicious crunchies every year. Farmers from miles around depend on the company to wash the nuts, dry them and send them on to the processing companies. FDA regulations are strict; moisture must be held at less than 8% – which requires a lot of heat. However, if the nuts dry out too quickly, they are ruined. Getting things “just right” is crucial to the taste of Keyawa Orchards’ product. Doing so cost-effectively is crucial to profit. Enter SolarWall. Ron...

Open the catalog to page 2All Conserval Engineering catalogs and technical brochures

-

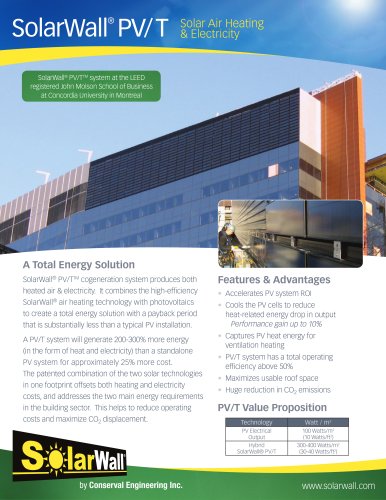

Solar Air Heating

2 Pages

-

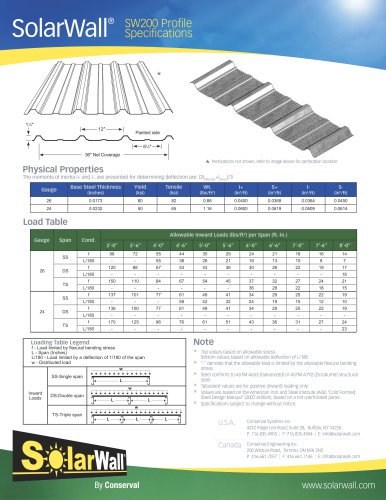

SW200 Profile Specifications

1 Pages

-

Solarwall

5 Pages

-

Institutional

1 Pages

-

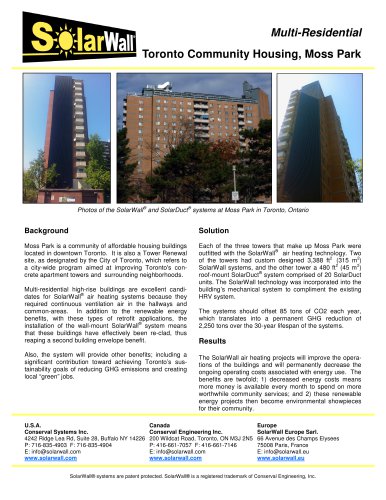

Multi-Residential

1 Pages

-

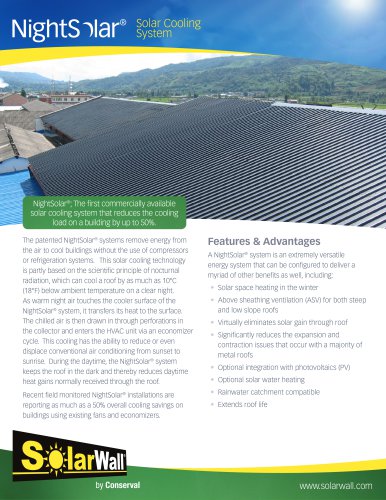

Nightsolar

2 Pages

-

SolarWall 2-Stage

2 Pages

-

SolarDuctSpec

2 Pages

-

SolarWallFans_2010

11 Pages

Archived catalogs

-

Crop Drying

2 Pages

-

Schools

2 Pages

-

Government & Military

2 Pages

-

Commercial Buildings

2 Pages

-

Industrial

2 Pages

-

Architects

2 Pages

-

SolarDuct and SolarDuct PV/T

2 Pages

-

Solarwall Brochure

7 Pages