Catalog excerpts

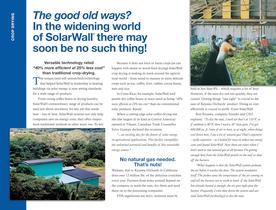

The good old ways? In the widening world of SolarWall® there may soon be no such thing! Versatile technology rated “40% more efficient at 25% less cost” than traditional crop-drying. The unique (and still unmatched) technology that helped SolarWall to leadership in heating buildings via solar energy is now setting standards for a wide range of products. From curing coffee beans to drying laundry, SolarWall’s extraordinary range of products can be used just about anywhere, for any job that needs heat – lots of heat. SolarWall systems not only help companies save on energy costs, they often outperform traditional methods in other ways, too. To wit: Because it does not burn or harm crops (as can happen with steam or wood-fired drying) SolarWall crop drying is making its mark around the agricultural world – from wood to manure to more delicate crops such as tea, coffee, fruit, rubber, cocoa beans, nuts and rice. In Costa Rica, for example, SolarWall roof panels dry coffee beans in ways rated as being “40% more efficient at 25% less cost” than do conventional solar products. Result: When a cutting-edge solar coffee-drying test site (the largest of its kind in Central America) opened in Tilaran, Canadian Trade Counsellor Sylvy Gariepy declared the occasion: “...an exciting day for the future of solar energy in agricultural applications. This facility exemplifies the unlimited potential and benefits of this renewable energy source.” No natural gas needed. That’s nuts! Walnuts, that is. Keyawa Orchards in California dries over 12 million lbs. of the delicious crunchies every year. Farmers from miles around depend on the company to wash the nuts, dry them and send them on to the processing companies. FDA regulations are strict; moisture must be held at less than 8% – which requires a lot of heat. However, if the nuts dry out too quickly, they are ruined. Getting things “just right” is crucial to the taste of Keyawa Orchards’ product. Doing so costeffectively is crucial to profit. Enter SolarWall. Ron Keyawa, company founder and CEO explains: “To dry the nuts, I need air that’s at 110°F, so if ambient is 80°F, then I need a 30° heat gain. I’ve got 600,000 cu. ft./min of air to heat, so at night, when things cool down here, I use a lot of natural gas! That’s expensive – really expensive – so I looked for ways to reduce my energy costs and found SolarWall. Now there are times when I don’t need to run natural gas at all because I’m getting enough heat from the SolarWall panels on the roof to shut off the burners. “What happens is that the SolarWall system preheats the air before it reaches the fans. The system modulates itself. The probes sense the temperature of the air coming in and tell the burners not to work so hard. If the SolarWall has already heated it enough, the air goes right past the burner. Frequently I even shut down the system and use total SolarWall [technology] to dry the nuts. CROP DRYING

Open the catalog to page 1

Canada Conserval Engineering Inc. 200 Wildcat Road, Toronto, ON M3J 2N5 T: 416.661.7057 F: 416.661.7146 E: info@solarwall.com W: www.solarwall.com U.S.A. Conserval Systems Inc. 4242 Ridge Lea Rd., Suite 28, Buffalo, New York 14226 T: 716.835.4903 F: 716.835.4904 E: solarwallUSA@solarwall.com W: www.solarwall.com “In the day, most of the time the system is on low fire – in other words, it’s barely on. Sometime before 10:00 a.m., when the sun starts hitting and the SolarWall really kicks in, I turn off the heater system because I don’t need the burners. Then, after 3:00 p.m. or so, I fire up...

Open the catalog to page 2All Conserval Engineering catalogs and technical brochures

-

Solar Air Heating

2 Pages

-

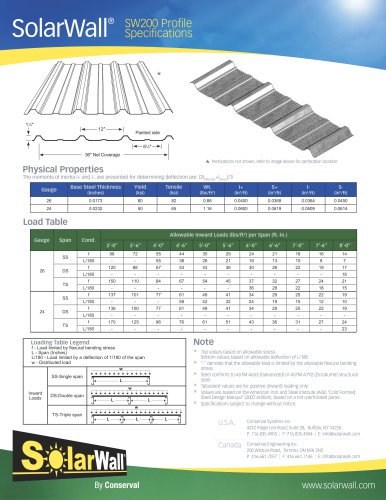

SW200 Profile Specifications

1 Pages

-

Solarwall

5 Pages

-

Institutional

1 Pages

-

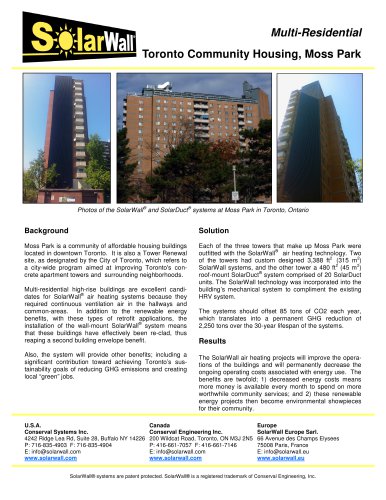

Multi-Residential

1 Pages

-

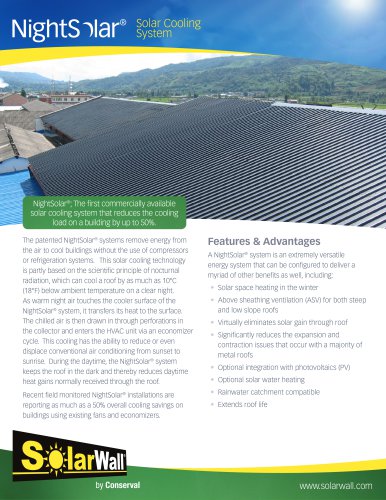

Nightsolar

2 Pages

-

SolarWall Process Drying

2 Pages

-

SolarWall 2-Stage

2 Pages

-

SolarDuctSpec

2 Pages

-

SolarWallFans_2010

11 Pages

Archived catalogs

-

Schools

2 Pages

-

Government & Military

2 Pages

-

Commercial Buildings

2 Pages

-

Industrial

2 Pages

-

Architects

2 Pages

-

SolarDuct and SolarDuct PV/T

2 Pages

-

Solarwall Brochure

7 Pages