Catalog excerpts

M-SERIES CRAWLER DOZERS 1150M I 1650M I 2050M TECHNOLOGY THAT PAYS EXPERTS FOR THE REAL WORLD SINCE 1842

Open the catalog to page 1

M-SERIES CRAWLER DOZERS EXPERTS FOR THE REAL WORLD SINCE 1842 1842 1946 Allis-Chalmers is the first manufacturer to introduce a torque converter on dozers. In the 30s they had invented permanently lubricated track rollers and sealed and lubricated tracks. First Case dozer made in cooperation with ATC and promoted under Terratrack brand. Case acquires ATC and is the first manufacturer to introduce tracks counterrotation on the 1000 Series Terratrack dozer

Open the catalog to page 2

HERITAGE A TRADITION OF INDUSTRY FIRSTS FIAT acquires Allis-Chalmers and in the 70s introduces the exclusive “Equistatic” geometry on bulldozer machines. In the late 90s Case launches its exclusive “CASE Extended Life Track” undercarriage. Case introduces the “Dual Path” hydrostatic transmission on the “K” series. Case is the first to introduce SCR technology on the “M” series dozer. Case extends its European product line-up with the n

Open the catalog to page 3

M-SERIES CRAWLER DOZERS LOW EMISSIONS Premium Tier 4 technology The state-of-the-art common rail engine delivers top performance in load response, max torque, power and fuel economy. The combustion is optimised for maximum efficiency: it occurs at high temperatures and uses 100% fresh, cool air, as the air intake is separated from the exhaust. The turbocharged engine with an Air-to-Air intercooler relies on well proven multi injection technology to maximize torque back-up and fuel efficiency with reduced engine noise and vibrations. 1 The high temperature combustion produces a very limited...

Open the catalog to page 4

ENGINE AND TRANSMISSION DRAWBAR PULL LEADERSHIP EXTRA POWERED TRANSMISSION Unmatched drawbar pull The entirely re-engineered transmission offers best-in-class pulling capacity combined with the typical manoeuvrability of the hydrostatic solution. The triple reduction final drive adds a planetary reduction to the standard double one. The hydrostatic transmission can work at a faster speed, reducing the overall pressure and consequently the effort on the single components. The two final drives are directly flanged on the main frame for better effort distribution and easy disassembling for...

Open the catalog to page 5

M-SERIES CRAWLER DOZERS VERSATILE CONTROLS Agile and strong The operator has full control of the massive power of the M Series dozer. The electrohydraulic joystick enables them to customise the reversing and steering sensitivity for faster and more efficient cycles. The decelerator pedal can be set to reduce either travel speed only or both travel and engine speed. Automatic blade functions The advanced electronics functions enable the operator to control specific functions in addition to the standard blade movements: - the on-board computer can be set directly from the joystick; - the blade...

Open the catalog to page 6

CUSTOMIZABLE CONTROLS PRODUCTIVITY BOOSTING ELECTRONICS BLADE CONTROL SET UP Flexible performance The M series is ready to work with the most common blade controls available on the market. The machine can be prepared in the factory for a specific configuration, ensuring perfect wire layout, visibility and component integration, guaranteeing the high standards of reliability of every Case product are maintained. HIGH VERSATILITY Tools for every task A wide offering of implements and equipments can be installed on the new CASE dozer: • Drawbar • 3 shanks parallel ripper • Front cab protections...

Open the catalog to page 7

QUICK GROUND ACCESS FOR SERVICING SAFE AND EASY MAINTENANCE Ground access for servicing The hydrostatic transmission brings less complexity and lower maintenance requirements than a traditional one. Belly plates on the bottom of the machine provide excellent access to controls and transmission components. The final drive installation on the main dozer frame enables dismounting while leaving the hydrostatic components in place. The transmission can even be reached through the cab floor, so it can be serviced directly on the jobsite. The refueling points (Fuel/Ad Blue/Hydraulic Oil) are...

Open the catalog to page 8

THE SCIENCE BIT The Case SiteWatch telematics system uses a high-tech control unit mounted on each machine to collate information from that machine and from GPS satellites. This data is then sent wirelessly through the mobile communication networks to the Case Telematics Web Portal. SiteWatch: centralised fleet control benefits at your fingertips Measure your true asset availability and optimise it • Eliminate the “phantom fleet”: SiteWatch allows to identify spare units or under loaded machines on each site. • Become able to reallocate units where they are more needed. • Forward Maintenance...

Open the catalog to page 9

MAIN REASONS TO CHOOSE THE M-SERIES LOW EMISSIONS - The only dozer with SCR in the market: exceptional efficiency and fuel savings, no losses due to extra cooling needs. EXTRA POWERED TRANSMISSION - Dual path transmission - Continuous power transfer delivers more productivity, stepless shifting, absolute bulldozer controllability. - 3 stages final drives - High transmission final reduction lessens stress on the hydrostatic transmission and increases drawbar pull. BLADE CONTROL SET UP - Leading brands plug and play blade control system. HIGH VERSATILITY - The wide variety of options and...

Open the catalog to page 10

EASY MAINTENANCE HIGH VISIBILITY - The functional groups are located beside the cab for quick intervention. - The transmission components can be checked directly under the cab floor. - The cab, positioned 100 mm forward, ensures best-in-class visibility on the blade corner as well as better bulldozer weight distribution. SUPERIOR COOLING EFFICIENCY - Double cooling surface and no overlapping of radiators. The reversible fan keeps the exchanging area clean and dramatically extends service intervals. BULLDOZER “EQUISTATIC” GEOMETRY - Emphasizes blade tilting while compensating twisting effort...

Open the catalog to page 11

M-SERIES CRAWLER DOZERS 1150M SPECIFICATIONS ENGINE ELECTRICAL SYSTEM Model ___________ Case Family 4, F4HFE613Z*A005 Tier 4 Interim Cylinders ___________________________________________6 Displacement ____________________________________ 6.7 l Fuel injection ____________________________________ Direct Fuel filter ________________________ Spin-on w/ in-line strainer Air intake____________________________________Cross-flow Cooling ________________________________________ Liquid Engine speeds ____________________________________ RPM High idle – no load ___________________________ 2200 +/- 50...

Open the catalog to page 12All Case Construction catalogs and technical brochures

-

Full-Line

12 Pages

-

Compact Track Loaders

24 Pages

-

G-SERIES WHEEL LOADERS

24 Pages

-

CX290D

4 Pages

-

CX210D

28 Pages

-

M-SERIES CRAWLER DOZERS

24 Pages

-

F-SERIES COMPACT WHEEL LOADERS

12 Pages

-

WHEELED EXCAVATORS WX148 I WX168

24 Pages

-

WHEELED EXCAVATORS WX188 I WX218

24 Pages

-

F series

12 Pages

-

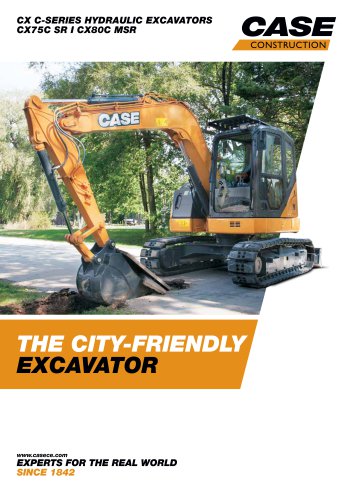

CX75C SR, CX80C MSR

20 Pages

-

SSL-CTL range

20 Pages

-

CX15B, CX18B

16 Pages

Archived catalogs

-

521F, 621F

12 Pages