Catalog excerpts

D-SERIES CRAWLER EXCAVATORS EXPERTS FOR THE REAL WORLD

Open the catalog to page 1

HERITAGE A TRADITION OF INDUSTRY FIRSTS EXPERTS FOR THE REAL WORLD SINCE 1842 1842 CASE is founded. 1869 The first CASE portable steam engine - road construction is born. 1957 The first factory integrated loader/backhoe in the world: a CASE industry first. 1969 CASE begins skid steer loader production. 1992 Sumitomo becomes supplier to CASE Corporation distributing excavators ranging from 7 to 80 tons. 1998 Global Alliance signed between CASE Corporation and Sumitomo. 2001 CASE introduces the first of its CX excavators, powerful new “thinking machines” designed to enhance productivity through...

Open the catalog to page 2

CRAWLER EXCAVATORS D-NA BUILT TO LAST AND CONTROL HIGH RELIABILITY Improved D-esign for D-urable perfomances • The boom and arm have been redesigned according to the latest stress analysis criteria to reduce stress points. • The undercarriage has been redesigned and reshaped to facilitate the welding process, enhancing the reliability of the fabricated structures. The One-Side-Slope lower frame design reduces the time needed to clean the undercarriage. • The size of the undercarriage component has been increased, especially in those parts where a high level of protection is required for...

Open the catalog to page 3

D-SERIES CRAWLER EXCAVATORS Smooth control with the CASE Intelligent Hydraulic System The proven CASE Intelligent Hydraulic System (CIHS) delivers energy savings in all cycle time phases (digging, boom up and swing, dumping). High performance hydraulics control • The new electrically controlled pumps deliver faster cycle times. • Oil flow can be adjusted according to working needs, or increased smoothly while starting travel and boom down. • As a result, the machine responsiveness to operation load is multiplied, resulting in cycle times up to 10% faster than the previous generation. Working...

Open the catalog to page 4

HIGH EFFICIENCY Great performances with low fuel consumption CASE advanced energy management provides solid fuel saving opportunities and lower emissions, and helps to prolong the life of the machine. It consists of 5 Energy Saving controls: • Torque control decreases main pump loads to prevent a drop in engine rpm, with improved sensitivity to control/ monitor main pump loads • Boom Economy Control (BEC) increases fuel efficiency during boom lower and swing operations, like dump unloading • Swing Relief Control (SWC) carefully manages the hydraulic power distribution in slewing operations...

Open the catalog to page 5

D-SERIES CRAWLER EXCAVATORS COMFORTABLE AND SAFE CAB The ultimate interior cab configuration • Superior cab structure with ample legroom for the operator. • Fully adjustable workstation. • New ergonomically designed high back seat with air suspension for excellent comfort. • Optional seat tilting adjustment and seat heater. • Top class features include the 178 mm colour LED Monitor, bluetooth tuner and Radio, spacious storage compartment, 12v accessory plug, clipboard holder, mobile phone holder, warm and cool box, fuse box service connection, storage tray and ergonomic arm rest. SMOOTH...

Open the catalog to page 6

COMFORT RULES FIRST CLASS CAB AND SEAT

Open the catalog to page 7

D-SERIES CRAWLER EXCAVATORS SAFE OPERATION ROPS cab and FOPS level II A safe working environment for the operator: • Reinforced structure of the cab compliant with ROPS/FOPS requirements. • Standard head protection approved to FOPS Level 2. • Wide offering of optional front guards. • Optional factory fitted travel alarm for greater safety on the jobsite around the machine. OUTSTANDING VISIBILITY Cab designed to create a perceptibly safe and secure working environment: • Ample glazed surface. • Rear and side view camera. • Unique 178 mm LED monitor with continuous camera view. • Efficient use...

Open the catalog to page 8

SAFETY AND MAINTENANCE WORK SAFELY IN ALL CONDITIONS SAFE ACCESS TO UPPERCARRIAGE EASY MAINTENANCE Solid and robust platform and handrails • All filters and regular fill points are grouped for easy access. • Engine oil change intervals set at 500 hours. • Radiator and cooler cores mounted side by side for easy access. • Standard 100 l/min refueling pump with automatic cut off. • Optional hydraulic and engine oil sampling port accessible at ground level for easy oil check. • Battery Shutdown Switch for safe maintenance on the electrical system. • All the D-series crawler excavators feature...

Open the catalog to page 9

MAIN REASONS TO CHOOSE THE D-SERIES HIGH PRECISION AND CONTROLLABILITY CASE Intelligent Hydraulic System (CIHS): synonymous with high performance smooth control. HIGH RELIABILITY Reliability and durability with the new redesigned arm, boom and undercarriage. HIGH VERSATILITY - 3 available power modes to match customer needs (A, H, SP) - Auto Power boost job-sensing hydraulic pressure increase. - Retractable undercarriage or LC chassis - Wide offering of track shoes size, included the 600 mm steel double grouser shoes HIGH EFFICIENCY - Energy saving system to take advantage of all fuel...

Open the catalog to page 10

10% FASTER - New electronically controlled hydraulic pumps OUTSTANDING VISIBILITY - Wide glazed area - Rear and side view - Large LED monitor - Optional LED lighting package SMOOTH RIDE, QUIET WORK ENVIRONMENT - Cab with cushioning system - Low noise and vibration COMFORTABLE AND SAFE CAB - Extra spacious cab - Fully adjustable workstation - New high back seat LOW EMISSIONS - EU Stage IV/Tier4 final compliant - No DPF - DOC and SCR-only maintenance-free components SAFE OPERATION AND MAINTENANCE - ROPS cab and FOPS level II - Standard extended handrails and guardrails - Optional factory fitted...

Open the catalog to page 11

THE SCIENCE BIT The Case SiteWatch telematics system uses a high-tech control unit mounted on each machine to collate information from that machine and from GPS satellites. This data is then sent wirelessly through the mobile communication networks to the Case Telematics Web Portal. SiteWatch: centralised fleet control benefits at your fingertips Measure your true asset availability and optimise it • Eliminate the “phantom fleet”: SiteWatch allows to identify spare units or under loaded machines on each site. • Become able to reallocate units where they are more needed. • Forward Maintenance...

Open the catalog to page 12All Case Construction catalogs and technical brochures

-

Full-Line

12 Pages

-

Compact Track Loaders

24 Pages

-

G-SERIES WHEEL LOADERS

24 Pages

-

CX290D

4 Pages

-

CX210D

28 Pages

-

M-SERIES CRAWLER DOZERS

24 Pages

-

F-SERIES COMPACT WHEEL LOADERS

12 Pages

-

WHEELED EXCAVATORS WX148 I WX168

24 Pages

-

WHEELED EXCAVATORS WX188 I WX218

24 Pages

-

F series

12 Pages

-

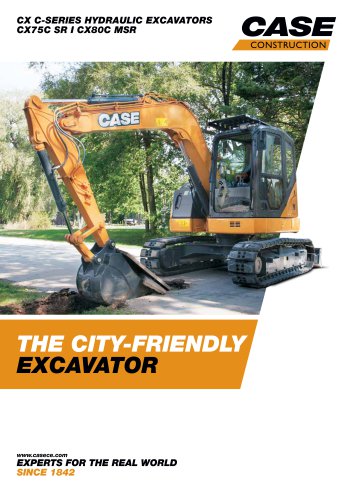

CX75C SR, CX80C MSR

20 Pages

-

SSL-CTL range

20 Pages

-

CX15B, CX18B

16 Pages

Archived catalogs

-

521F, 621F

12 Pages