Catalog excerpts

Product Data AquaEdge® High-Efficiency Semi-Hermetic Centrifugal Liquid Chillers 500 to 800 Nominal Tons (1758 to 2814 Nominal kW) 19DV 50/60 Hz High-Efficiency Semi-Hermetic Centrifugal Liquid Chillers with Greenspeed® Intelligence, PIC 6 Controls, and HFO-1233zd(E) Refrigerant

Open the catalog to page 1

Features/Benefits The 19DV AquaEdge® chiller’s use of low GWP (global warming potential) refrigerant 1233zd(E) and its high efficiencies obtained from real world operating conditions greatly diminish the effects of potential direct or indirect global warming. Carrier’s AquaEdge centrifugal chillers offer: • The use of non-ozone depleting (ODP=0.00) refrigerant HFO1233zd(E), which is not affected by scheduled US EPA refrigerant phaseouts • An annual leak rate of 0.1%, one of the lowest published in the industry • Semi-hermetic compressor • Variable speed drive • Modular construction • Low...

Open the catalog to page 2

Using air instead of water also eliminates costly maintenance associated with the water cooling pump, heat exchanger and rubber tubing used with water-cooled VFDs. A factory-installed active harmonic filter option is also available. Heat exchanger features The American Society of Mechanical Engineers (ASME) standard requires the use of an independent agency to certify the design, manufacture, and testing of all heat exchangers, ensuring the ultimate in heat exchanger safety, reliability, and long life. Industry first low-pressure hybrid falling film evaporator The hybrid falling film...

Open the catalog to page 3

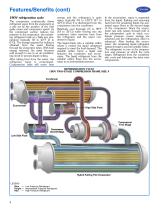

Features/Benefits (cont) 19DV refrigeration cycle The compressor continuously draws refrigerant vapor from the evaporator at a rate set by the position of the inlet guide vanes and compressor speed. As the compressor suction reduces the pressure in the evaporator, the remaining refrigerant boils at a fairly low temperature (typically 38 to 42°F [3 to 6°C]). The energy required for boiling is obtained from the water flowing through the evaporator tubes. With heat energy removed, the water becomes cold enough to use in an air-conditioning circuit or process liquid cooling. After taking heat...

Open the catalog to page 4

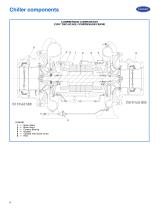

Model number nomenclature19DV TWO-STAGE COMPRESSOR FRAME SIZE 419DV-G44G44 4 Description 19 — High Efficiency Semi-Hermetic Centrifugal Chiller D — Low Pressure V — Variable Speed Drive Evaporator Frame Size, Length, Pass Arrangement, and Tube Count G20 - G4K — Frame G H20 - H4K — Frame H Condenser Frame Size, Length, Pass Arrangement, and Tube Count G22 - G4K — Frame G H22 - H4K — Frame H Compressor Frame Size 4 — 500-800 nominal tons (1758-2813 kW) Special Order Indicator --Standard S — Special Order Motor Code* B — Smallest HP D — Small-Mid HP F — Mid-Large HP H — Largest HP VFD Code* 5...

Open the catalog to page 5

COMPRESSOR COMPONENTS 19DV TWO-STAGE COMPRESSOR FRAME 1ST STAGE SIDE LEGEND 1 — Motor Stator 2 — Motor Rotor 3 — Ceramic Bearing 4 — Impeller 5 — Variable Inlet Guide Vanes 6 — Filter

Open the catalog to page 6

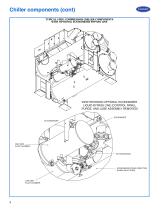

TYPICAL 19DV COMPRESSOR CHILLER COMPONENTS FRONT VIEW 1 — Interconnecting Compressor Piping 2 — VFD Drain (Field Drain Piping Required) 3 — Condenser 4 — Condenser Waterbox Return End 5 — Economizer Isolation Valve (Option) 6 — Economizer 7 — Evaporator Waterbox Return End 8 — Vacuum/Charging Valve (Hidden) 9 — PIC6 HMI Touchscreen Panel 10 — Evaporator Bundle Sight Glasses 11 — Rupture Disc 12 — Suction Elbow 13 — Evaporator Charging Valve and Evaporator Pressure Transducer 14 — First Stage Guided Vane Actuator 15 — Compressor Motor 16 — Moisture Indicator (Hidden) 17 — Evaporator 18 —...

Open the catalog to page 7

Chiller components (cont) TYPICAL 19DV COMPRESSOR CHILLER COMPONENTS WITH OPTIONAL ECONOMIZER BYPASS LINE VIEW SHOWING OPTIONAL ECONOMIZER LIQUID BYPASS LINE (CONTROL PANEL, PURGE, AND LUBE ASSEMBLY REMOVED) ECONOMIZER TO CONDENSER HIGH SIDE FLOAT CHAMBER ECONOMIZER BYPASS DIRECTION (WHEN VALVE OPEN) LOW SIDE FLOAT CHAMBER

Open the catalog to page 8

19DV chiller weight The weight of a 19DV chiller is best obtained by running the chiller selection software. The 19DV has an extensive number of possible combinations of evaporators (including tubing type and length), condensers (including tubing type and length), waterbox types (taking into account heat exchanger passes), compressors, motors, and system accessories. The 19DV selection software will determine the rigging weight, operating weight, corner weight, and spring deflection (if applicable) of any configured unit. Due to rigging and installation considerations, there are times when...

Open the catalog to page 9

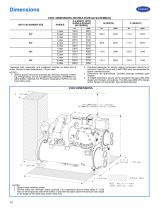

19DV DIMENSIONS (NOZZLE-IN-HEAD WATERBOX) HEAT EXCHANGER SIZE ‘Assumes both evaporator and condenser nozzles on same end of chiller; Nozzle-in-head waterboxes, 150 psi rated. NOTES: 1. Service access should be provided per American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) 15, latest edition, National Fire Protection Association (NFPA) 70, and local safety code. 2. Overhead clearance for service rigging compressor should be at minimum 3 feet (914 mm) with 5 feet (1524 mm) recommended for easier overhead access. 3. Dimensions are approximate. Certified...

Open the catalog to page 10

19DV DIMENSIONS (MARINE WATERBOX, 150 PSIG) ‘Assumes both evaporator and condenser nozzles on same end of chiller; Nozzle-in-head waterboxes, 150 psi rated. NOTES: 1. Service access should be provided per American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) 15, latest edition, National Fire Protection Association (NFPA) 70, and local safety code. 2. Overhead clearance for service rigging compressor should be at minimum 3 feet (914 mm) with 5 feet (1524 mm) recommended for easier overhead access. 3. Dimensions are approximate. Certified drawings available upon...

Open the catalog to page 11

The 19DV chiller can be tailored to the specific requirements of a given application. Please contact your local Carrier representative for a selection. The NG E-CAT selection software analyzes many factors, including specific temperature, fluid type, and flow requirements to automatically configure the chiller’s heat exchanger size, compressor aerodynamic model, and electrical sizing to deliver a chiller optimized to the job requirements. Heat exchangers Flow rate If the evaporator flow is variable, the rate of change of flow should not exceed 50% per minute. Water quality Please consult...

Open the catalog to page 12All CARRIER commercial catalogs and technical brochures

-

40UV-UH-14SI

32 Pages

-

42B-6SI

24 Pages

-

A WORLD OF COMFORT PRINT

10 Pages

-

A WORLD OF COMFORT

20 Pages

-

AirStream™ Room Fan Coils

4 Pages

-

The CRRSA Act (ESSER I)

2 Pages

-

A World of Comfort

2 Pages

-

Carrier-Catalogue-2018-2019

940 Pages

-

Axis™ Overhead Air Terminals

4 Pages

-

AERO® Air-Handling Units

4 Pages

-

30XA

136 Pages

-

30RAP

104 Pages

-

2019 Carrier Ductless

88 Pages

-

Carrier VRF

44 Pages

-

Special Seismic Compliance

1 Pages

-

Axis Overhead Air Terminals

2 Pages

-

Roomtop® 50AH036-072

24 Pages

-

OMNIZONE™ 50BV020-064

64 Pages

-

A World of Comfort

2 Pages

-

Low Noise Type CABINET FAN

16 Pages

-

Performance 16 Heat Pump

4 Pages

-

ComfortVIEW 3

6 Pages

-

VVT Zoning System

8 Pages

-

Heat Reclaim Chillers

2 Pages

-

Airstream Unit Ventilators

2 Pages

-

Airstream Room Fan Coils

2 Pages

-

Aero Air-Handling Units

2 Pages

-

17DA Centrifugal Chiller

2 Pages

-

AXIS? Overhead Air Terminals

3 Pages

-

Comfort? Series

2 Pages

-

GEMINI? 38AKS028-044

40 Pages

-

i-Vu Open Standard & Plus

2 Pages

Archived catalogs

-

ROOMAIR CONDITIONERS

6 Pages

-

AIRSTREAM™ Room Fan Coils

3 Pages

-

Water-Cooled Chillers

3 Pages

-

Antimicrobial Solutions

3 Pages