Website:

Bruag Design Factory AG

Website:

Bruag Design Factory AG

Catalog excerpts

Exterior Applications Perforated Façades CELLON® design Perforated Façades and Cladding technical data sheet for planning, construction and installation General Information Production Formats Individual panel division within the following planning formats: Our CELLON® panel is a Compact High-Pressure Laminate Panel (HPL) consisting of 70% cellulose sheets and 30% phenolic resin. The weather-resistant material is ideally suited for external applications such as façade claddings. The raw panels are cut project-specifically using laser technology. The panels are thus pre-cut to to the exact dimensions (incl. boreholes) and with the chosen perforation. After the cutting process the panels are coated. Depending on the perforation and the distance between the fixing points, panels with 8 mm or 10 mm thickness are used. CELLON® Design | Version 2.0

Open the catalog to page 1

When ordering Bruag CELLON® design panels, please note the following: The following file formats can be submitted: DWG / DXF files Cadwork 2D or 3D files Bruag CELLON® design panels must be drawn on a separate layer 1:1 scale drawing Measurement of at least one long and one short side to be able to verify the scale Boreholes (drawn as closed circle), cut-outs etc. are drawn Placeholder/Markings of areas where perforation shall be placed Custom patterns (If you have your own pattern, the following points should be observed) Pattern must be created as CAD drawing (DWG or DXF file) The...

Open the catalog to page 2

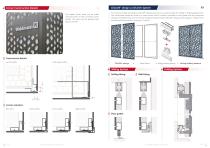

Construction Solutions Substructures for perforated façades are usually made of metal. In addition to conventional square tubes, angles or omega profiles are also suitable. If no substructure should be visible it is also possible to use punctual fixings in the form of Z-profiles. The substructure must be fixed to the wall according to the technical specifications and adapted to the load of CELLON® design panels. UV-resistant Membranes A.1 Continuous profiles on aluminum bracket Visible substructure Due to the open areas of a perforated façade, the layer behind may must meet higher...

Open the catalog to page 3

B.1 Continuous profiles on spacer screws Visible substructure C. Wooden Cross Slats C.1 Continuous metal profiles on wooden cross slats Wall Spacer screw Insulation UV-resistant membranes Metal profile (e.g. omega, Z, square tube) CELLON® façade panels B.2 Punctual profiles on spacer screws Invisible substructure Wall Wooden cross slats Insulation UV-resistant membranes Metal profile (e.g. omega, Z, square tube) CELLON® façade panels C.2 Punctual spacer sleeves on wooden cross slats Invisible substructure Visible substructure Wall Spacer screw Insulation UV-resistant membranes Punctual...

Open the catalog to page 4

E. Ventilated Double Skin Façade Visible substructure E.1 Continuous metal profiles on ventilated double skin façade Visible substructure D.1 Continuous profiles on wooden construction OSB board Insulation Wooden construction FORMBOARD TOP PINE Metal profile (e.g. omega, Z, square tube) 6 CELLON® façade panels OSB board Insulation Wooden construction FORMBOARD TOP PINE Punctual metal profile (e.g. Z, U) 6 CELLON® façade panels Invisible substructure D.2b Punctual spacer sleeves on wooden construction Complement/Renovation of other Wall Constructions Wall Insulation Horizontal slats...

Open the catalog to page 5

Invisible substructure F.2 Punctual spacer sleeves on solid wall H. Plastered External Wall Insulation with Additional Insulation H.1 Continuous metal profiles on double external wall Insulation (+ Plaster) Visible substructure 1 Wall 2 Spacer sleeve 3 CELLON® façade panels G. Plastered External Wall Insulation (Compact façade) G.1 Continuous metal profiles on plastered external wall insulation Wall Insulation Spacer screw Plaster Metal profile (e.g. omega, Z, square tube) 6 CELLON® façade panels G.2 Punctual metal profiles on plastered external wall insulation Wall Insulation Spacer screw...

Open the catalog to page 6

Corner Construction Details The façade corner areas can be made with butt joints or with a common corner profiles. The joint must be planned with approx. 6-8 mm. CELLON® design as Shutter System For the play of light and shadow. CELLON® design panels are very well suitable for sliding or folding applications. The customized panels are fixed on a metal frame, which is directly installed on the façade with the respective sliding or folding fittings. Due to the low weight of the perforated CELLON® design panels (approx. 7-9kg/m2) the handling of the elements is as easy as it can be. +...

Open the catalog to page 7

Bruag AG Bahnhofstrasse 8 8594 Güttingen Switzerland info@bruag.ch www.bruag.ch

Open the catalog to page 8All Bruag Design Factory AG catalogs and technical brochures

-

Innovative Cladding Elements

25 Pages

-

Ventilated Façade Solutions

9 Pages

-

Noise-Virus-Catcher®

1 Pages

-

Zeitgeist 2016

2 Pages

Archived catalogs

-

Acoustics Elements

3 Pages

-

Brève Information CELLON®

2 Pages

-

Zeitgeist 2015

4 Pages